It”s widely used for circuit board,weaving all kinds of fabrics in the scope of reinforcement ,insulation,corrosion resistance,heat resistance and so on.

Product performance introduction

Fiberglass Yarn Description:

Fiberglass yarn is a fiberglass twisting yarn.Its high strength, corrosion resistance, high temperature resistant, moisture absorption, good electrical insulating performance, used in weaving, casing, mine fuse wire and cable coating layer, the winding of electric machines and appliances insulating material, various machine weaving yarn and other industrial yarn.

Fiber Type: Glass fibers, typically made from soda-lime glass, borosilicate glass, or E-glass

Fiber Diameter: Typically ranges from 3-20 microns (μm)

Fiber Length: Can be continuous filament (not chopped or staple fibers) or chopped fibers of various lengths (e.g., 1/4″, 1/2″, 1″, etc.)

Tex Count: Measures the yarn’s linear density, with common tex counts ranging from 100 to 1000 Tex (1 Tex = 1 gram per kilometer)

Yarn Twist: Can range from 0 to 100 twists per meter (TPM), depending on the intended application and desired yarn properties

Yarn Color: Typically natural white or transparent, but can be colored through dyeing or pigmentation

Yarn Finish: Can have various finishes, such as lubricants, binders, or coatings, to enhance yarn performance and processing

Spinning Method: Can be wound, spooled, or tubed, depending on the specific product and manufacturer

134 Tex E-Glass Fiberglass Yarn Description:

Fiber Type: E-Glass (Electric Glass)

Tex Count: 134 Tex (a measure of the yarn’s linear density, where 1 Tex = 1 gram per kilometer)

Fiber Diameter: 10-12 microns (average fiber diameter)

Fiber Length: Continuous filament (not chopped or staple fibers)

Yarn Twist: 10-20 twists per meter (TPM) (may vary depending on the specific product and manufacturer)

Yarn Color: Natural white or customer-specified colors (dyeing and finishing options available)

Yarn Finish: Sizing and finishing treatments available to enhance yarn performance and processing (e.g., lubricants, binders, and coatings)

Spinning Method: Wound or spooled (may vary depending on the specific product and manufacturer)

134 Tex E-Glass Fiberglass Yarn Properties:

Physical Properties:

- Tex: 134 (Tex is a unit of measurement for the linear density of fibers, where 1 Tex = 1 gram per kilometer)

- Density: 2.55 g/cm³ (typical density of E-Glass fiberglass yarn)

- Fiber Diameter: 10-12 microns (typical fiber diameter of E-Glass fiberglass yarn)

Mechanical Properties:

- Tensile Strength: 3500-4000 MPa (508-580 ksi) (average tensile strength of 134 Tex E-Glass fiberglass yarn)

- Elongation at Break: 4.5-5.5% (average elongation at break of 134 Tex E-Glass fiberglass yarn)

- Modulus of Elasticity: 72-76 GPa (10.5-11.0 million psi) (average modulus of elasticity of 134 Tex E-Glass fiberglass yarn)

Thermal Properties:

- Melting Point: 1400°C (2550°F) (typical melting point of E-Glass fiberglass yarn)

- Thermal Conductivity: 0.8-1.2 W/mK (average thermal conductivity of 134 Tex E-Glass fiberglass yarn)

- Heat Deflection Temperature (HDT): 180-200°C (356-392°F) (average HDT of 134 Tex E-Glass fiberglass yarn)

Electrical Properties:

- Dielectric Strength: 10-15 kV/mm (average dielectric strength of 134 Tex E-Glass fiberglass yarn)

- Volume Resistivity: 10^14 Ω·cm (average volume resistivity of 134 Tex E-Glass fiberglass yarn)

Other Properties:

- Moisture Absorption: 0.2-0.5% (average moisture absorption of 134 Tex E-Glass fiberglass yarn)

- Chemical Resistance: Good resistance to many chemicals, including acids, alkalis, and solvents

- UV Resistance: Good resistance to ultraviolet (UV) light

- Flammability: Self-extinguishing, meets UL94 V-0 rating

Yarn Feature:

1. United quality.

2. Lower bubbles.

3. Consistent tex or linear density.

4. Good uniformity in twist.

5. Good manufacturing property and low fuzz.

6. High heat,Chemical and Flame Reslstance.

Principle of manufacturing:

Step 1: Glass Formula Formation

- The manufacturing process begins with the formation of a glass formula, which involves mixing silica sand, soda ash, limestone, and other ingredients to create a glass batch.

- The glass batch is then heated to a high temperature (around 1400°C) in a furnace to form a molten glass.

Step 2: Fiber Formation

- The molten glass is then formed into fibers through one of two methods:

- Direct Drawing: The molten glass is drawn through a spinneret, which is a metal plate with tiny holes, to create fibers of the desired diameter.

- Marbleizing: The molten glass is cooled and formed into small, spherical marbles, which are then heated and stretched to create fibers.

Step 3: Fiber Cooling and Solidification

- The fibers are then cooled and solidified through a process called “attenuation,” which involves stretching and cooling the fibers rapidly to prevent crystallization.

- The fibers are cooled to around 500°C to 600°C, at which point they become solid and rigid.

Step 4: Fiber Treatment

- The fibers are then treated with a chemical coating, known as a “size,” to improve their strength, durability, and processability.

- The size coating helps to reduce the fiber’s surface energy, making it more compatible with other materials and improving its overall performance.

Step 5: Winding and Texturizing

- The fibers are then wound onto a spindle or bobbin, and may undergo additional processing, such as texturizing, to create the desired yarn texture and properties.

- Texturizing involves crimping or twisting the fibers to create a more textured, bulkier yarn.

Step 6: Yarn Finishing

- The yarn is then treated with additional chemicals, such as lubricants, finishes, or dyes, to enhance its performance, appearance, and processability.

- The yarn may also undergo additional processing, such as winding, cutting, or packaging, to prepare it for use in various applications.

Step 7: Quality Control

- The final step involves quality control measures, such as testing the yarn’s strength, elasticity, and other properties to ensure it meets the required specifications.

This is a general overview of the principle of manufacturing fiberglass yarn. The exact process may vary depending on the specific manufacturer and the intended application of the yarn.

134 Tex E-glass Fiberglass Yarn Application:

1.Woven Fiberglass mesh (general yarn for warp, roving for weft)

2. Weaving various electronic cloth

3. Braided cable wire Cladding

4.Braided casing

5.Braided fuse

6.Insulation materials for making electrical windings ,etc.

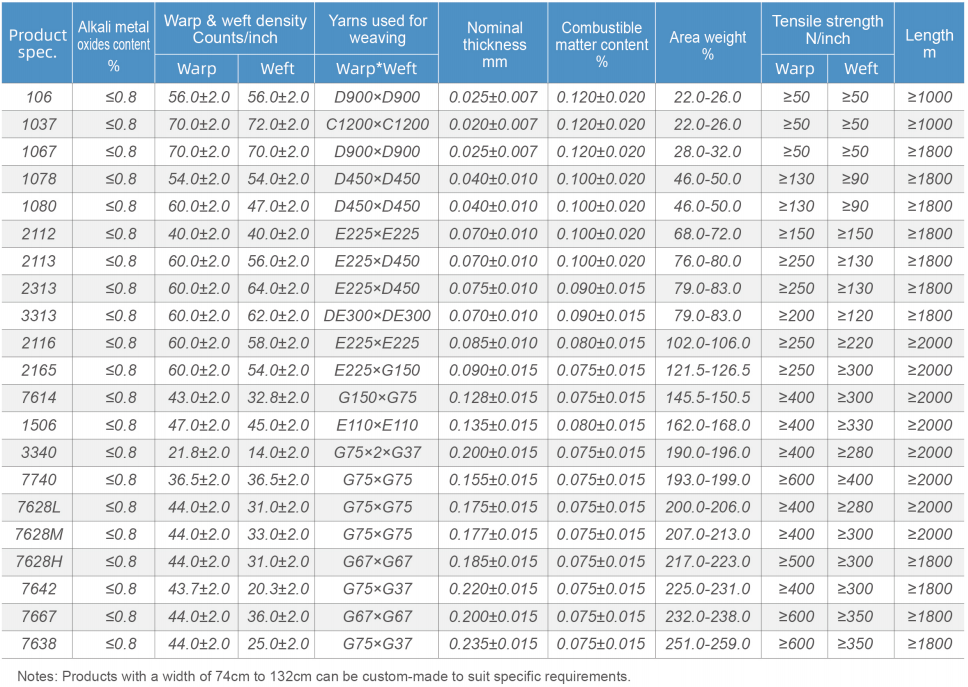

Technical Data:

Packaging And Storage:

The products are mainly packaged in cartons or metal frames. Unless otherwise specified, the products should be stored in a dry, cool and moisture-proof area. The room temperature should be maintained in an appropriate range,preferably between 15°C~35°C. lt is best if the product is used within 12 months after the production date. The products should be kept in their original packaging prior to use.

To ensure safety and avoid damage to the products, the pallets should be stacked no more than two layers high When the pallets are stacked in 2 layers, special care should be taken to correctly and smoothly move the upper pallet.

Strong Market Presence:

As trusted fiberglass yarn suppliers, we offer competitive wholesale prices and ensure reliable supply across various sectors. Whether you need robust weaving solutions, durable casing materials, or efficient electrical insulation, our E-Glass Fiberglass Yarn meets your requirements with excellence. Count on our commitment to quality and innovation to enhance your manufacturing processes.

Contact us today to learn more about our E-Glass Fiberglass Yarn offerings and how we can support your specific needs. Elevate your industrial operations with our premium fiberglass yarn solutions!

After-sales service:

Fast delivery, affordable prices, enthusiastic full service, contact us immediately.

134 Tex E-glass Fiberglass Yarn

Series :

Proxy Products >application

Braided fuse Insulation materials for making electrical windings ,etc.

Brand name :

TFcomposite

Product name :

134 Tex texturised fiberglass yarn

Material :

Fiberglass

Fiberglass Yarn :

For Fiberglass Cloth

FAQ

Q :

What's the MOQ?

A :

Usually 1 Ton

Q :

What's your delivery time for production?

A :

If we have stock , can delivery in 7 days ; if without the stock, need 7~15 days !

Other related products