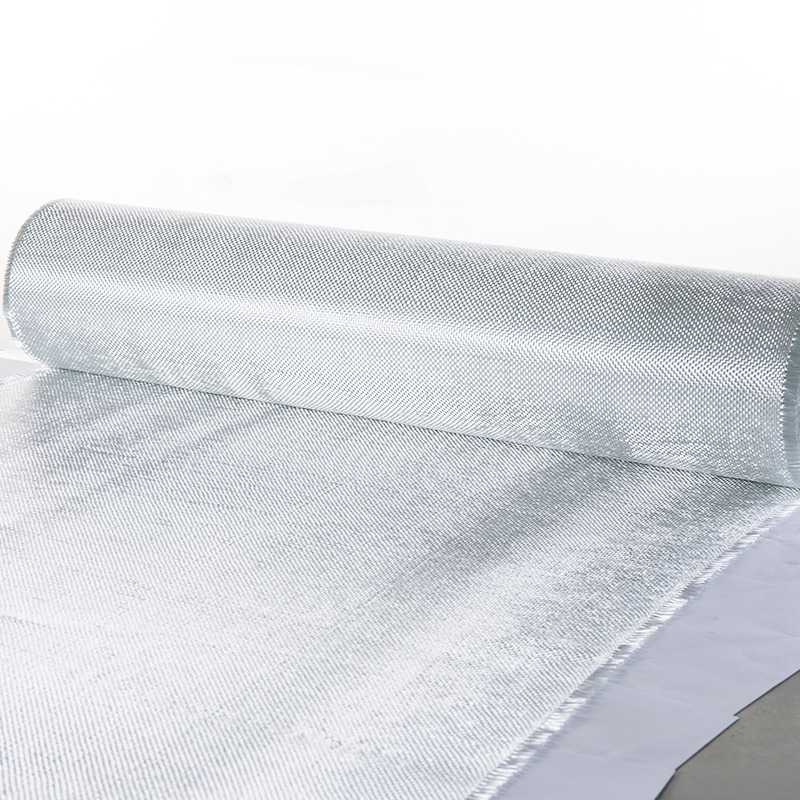

Fiberglass ripstop is a plain two-way reinforced fabric woven from untwisted roving.

Product performance introduction

200g E-glass Fiberglass Woven Roving Description

Heat-resistant fiberglass woven roving is compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins. It’s widely used in hand lay up, mold press, grp forming process and robot processes to manufacture boats, vessels, plane, automobile parts, panels, storage tanks .

The 200g E-glass Fiberglass Woven Roving is a high-quality, woven roving fabric made from E-glass fibers, designed for use in a variety of industrial applications. This product features a specific areal weight of 200g/m², making it suitable for applications where moderate strength and durability are required.

Key Features:

- E-glass Fibers: The 200g E-glass Fiberglass Woven Roving is made from E-glass fibers, which provide excellent mechanical properties, including tensile strength, impact resistance, and durability.

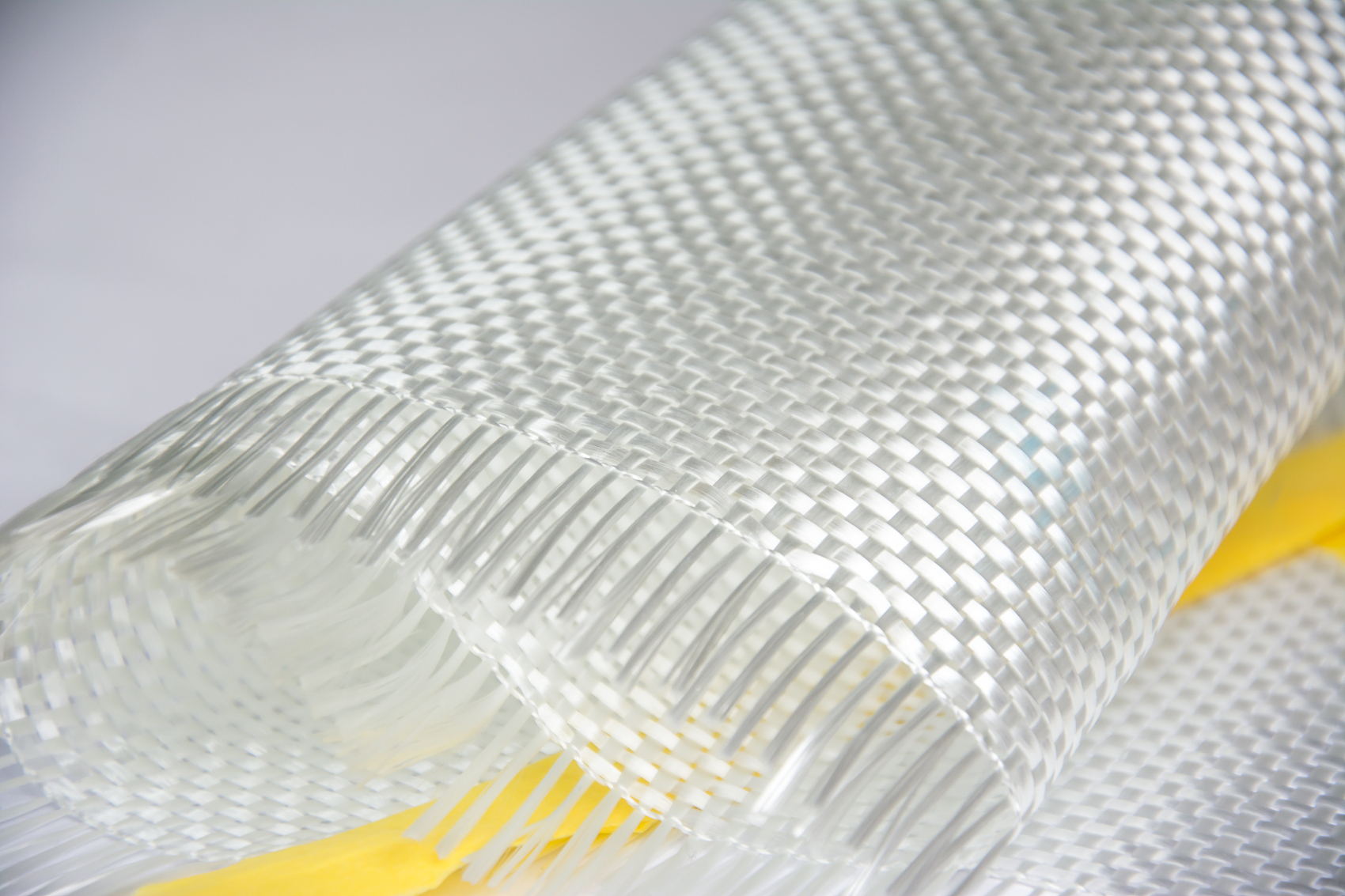

- Woven Roving Fabric: The E-glass fibers are woven into a roving fabric, which provides excellent drapeability, making it suitable for applications with complex geometries.

- Areal Weight: The 200g E-glass Fiberglass Woven Roving has an areal weight of 200g/m², making it suitable for applications where moderate strength and durability are required.

- Thickness: The thickness of the roving fabric is approximately 0.3-0.5 mm, making it suitable for applications where thin layers are required.

- Weave Pattern: The E-glass fibers are woven into a plain weave pattern, providing excellent mechanical properties and drapeability.

Technical Specifications:

- Areal weight: 200g/m²

- Thickness: 0.3-0.5 mm

- Fiber diameter: 10-15 μm

- Material: E-glass

- Weave pattern: Plain weave

- Thread count: 12-15 threads/cm

- Breaking strength: ≥ 300 MPa

- Elastic modulus: ≥ 70 GPa

- Elongation at break: ≥ 2.5%

Benefits:

- High Mechanical Strength: The 200g E-glass Fiberglass Woven Roving provides excellent mechanical properties, making it suitable for applications where moderate strength and durability are required.

- Good Drapeability: The woven roving fabric provides excellent drapeability, making it suitable for applications with complex geometries.

- Easy to Handle: The 200g E-glass Fiberglass Woven Roving is easy to handle and transport, reducing labor costs and improving production efficiency.

- Cost-Effective: The 200g E-glass Fiberglass Woven Roving is a cost-effective solution for composite materials manufacturing, offering a competitive advantage in various industries.

Applications:

- Automotive: Exterior components, such as body panels, spoilers, and trim.

- Aerospace: Secondary aircraft components, such as interior trim and components.

- Marine: Boat hulls, decks, and other structural components.

- Industrial: Machinery parts, such as covers and casing.

- Sports Equipment: Composite sports equipment, such as surfboards, skateboards, and bicycle frames.

Comparison to Other Products:

The 200g E-glass Fiberglass Woven Roving is similar to the 250g E-glass Fiberglass Woven Roving, but with a lower areal weight and slightly lower mechanical strength. It is also similar to the 150g E-glass Fiberglass Woven Roving, but with a higher areal weight and slightly higher mechanical strength.

Description of use

The reinforcement,in form of fiberglass strands, mat or woven roving, is first laid into amold which has been coated with a release agent and agel coat. Then a resin mix is applied by hand using a brush or spray gun. A roller is then used to ensure uniform impregnation, complete glass wet-out and removal of any trapped air bubbles. This operation is repeated until the desired thickness of the structure is obtained. After curing at room temperature or under heating conditions,the finished parts are formed.

200g E-glass Fiberglass Woven Roving

Series :

Proxy Products >application

Ship,Construction,AutomobilesTrucks, Chemicals,Electrical andSports and wind energy etc.

Brand name :

TFcomposite

Product name :

200g fiberglass woven roving

Material :

Fiberglass

FAQ

Q :

When can I offer?

A :

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price pls call us or tell us in your email , so that we can reply you priority.

Q :

What's your delivery time for production?

A :

If we have stock , can delivery in 7 days ; if without the stock, need 7~15 days !

Other related products