Fiberglass reinforced plastic grating (also known as FRP grating, glass reinforced plastic grating or fiberglass grating) is a composite material manufactured by combining a matrix of resin and fiberglass. FRP grating is a structural product that can be weight-bearing between spans.

Product performance introduction

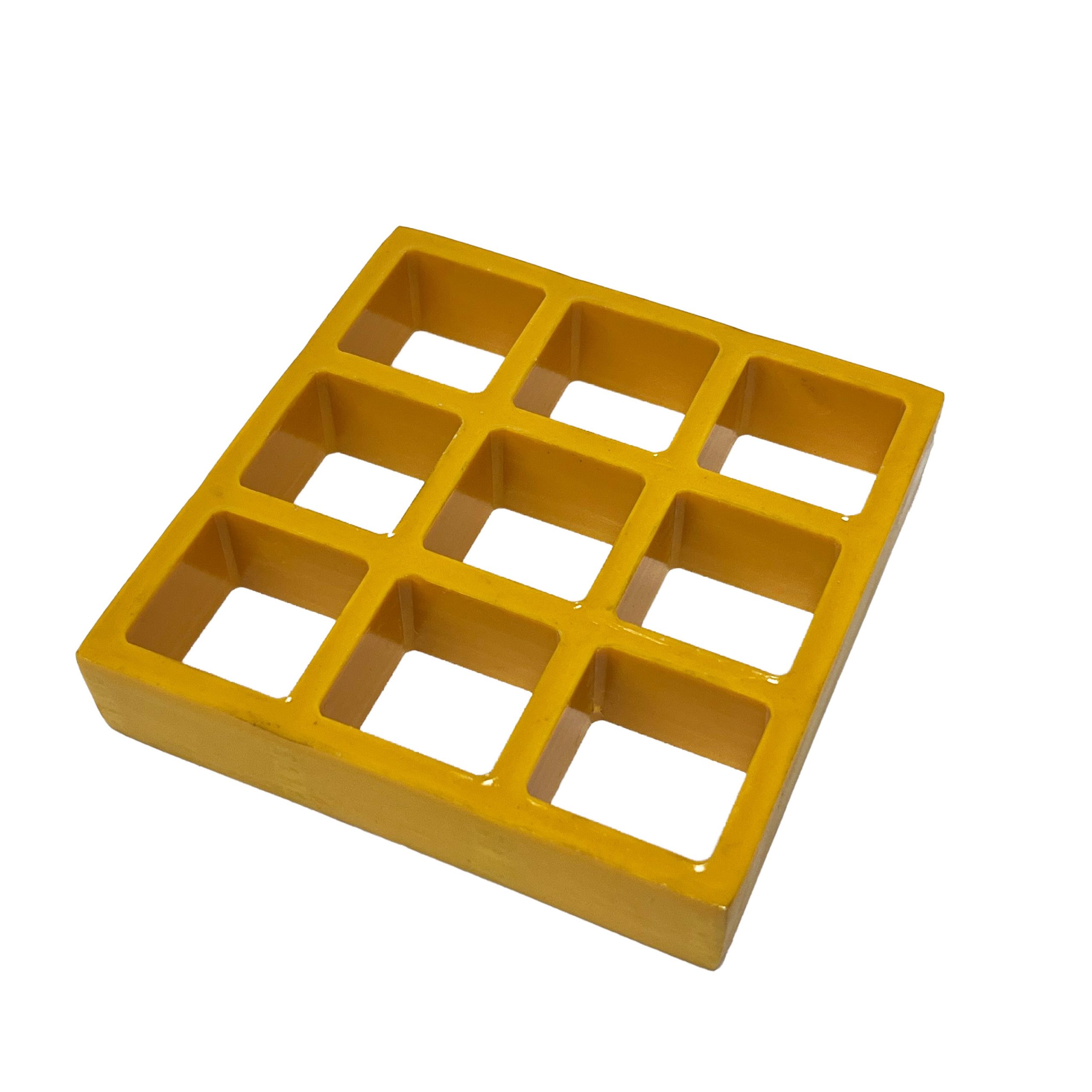

25MM FRP Molded Grating

Molded Grating is made from polyester resin and continuous fiberglass roving, heat cured in a mold, in a hand-crafted layer-by-layer operation to produce the desired thickness and panel size. Grating produced using this technique have 30-35% (total weight) glass fiber reinforcement. The one-piece interwoven mesh construction of the molded grating produces a product with optimal corrosion resistance and bi-directional strength. Since the grating is “cast” in one piece, there is no mechanical joint between bearing bars, unlike pultruded grating where the glued joints can give way in heavy continuous traffic or after prologged service.

The high percentage of resin (65%) in molded grating provides superior corrosion resistance and optimal impact resistance. Molded fiberglass gratings with a square mesh pattern offer increased load capacity and panel utilization due to its bi-directional nature.

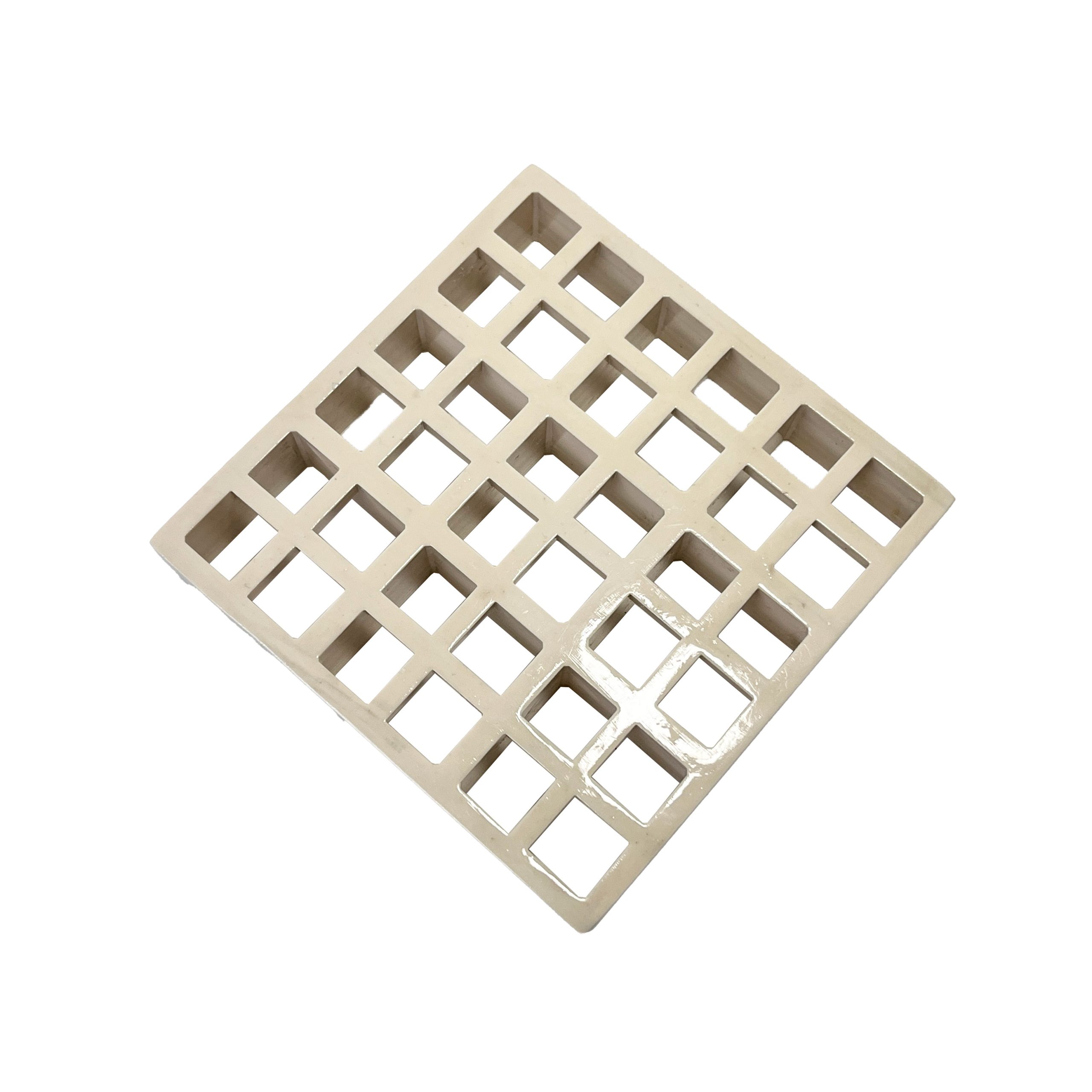

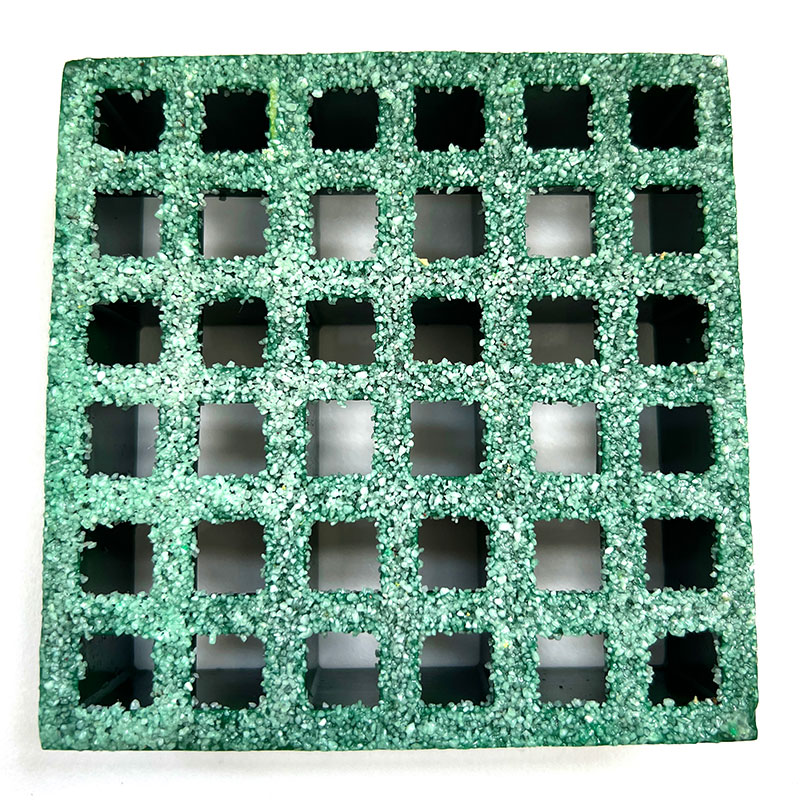

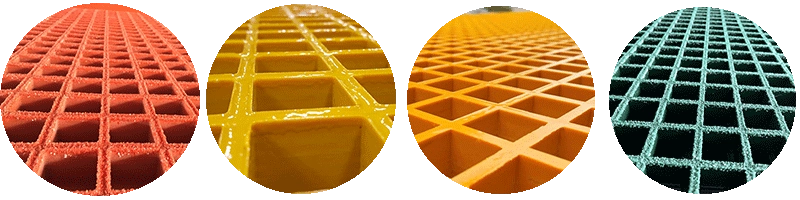

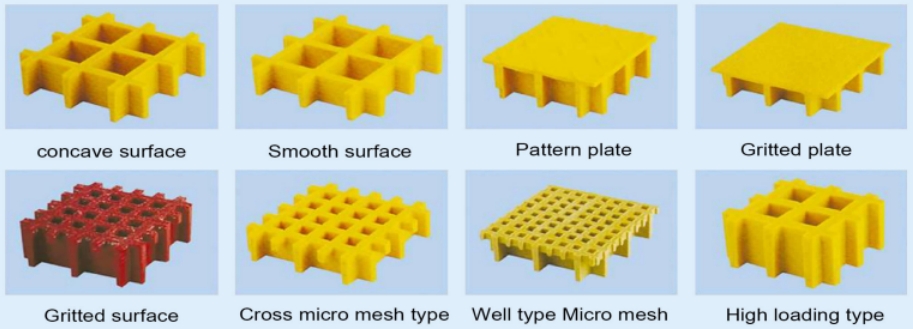

And for different application, the surface can be chosed from smooth, concave, gritted or solid-top.

Molded grating surface

- Concave surface

- Smooth surface

- Pattern plate

- Gritted plate

- Gritted surface

- Cross micro mesh type

- Well type Micro mesh

- High loading type

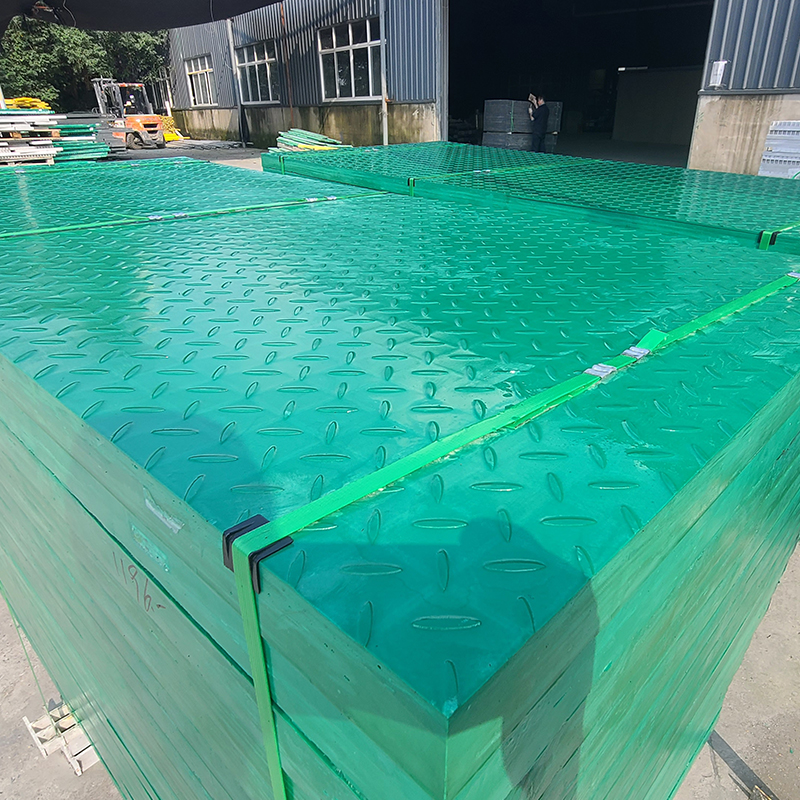

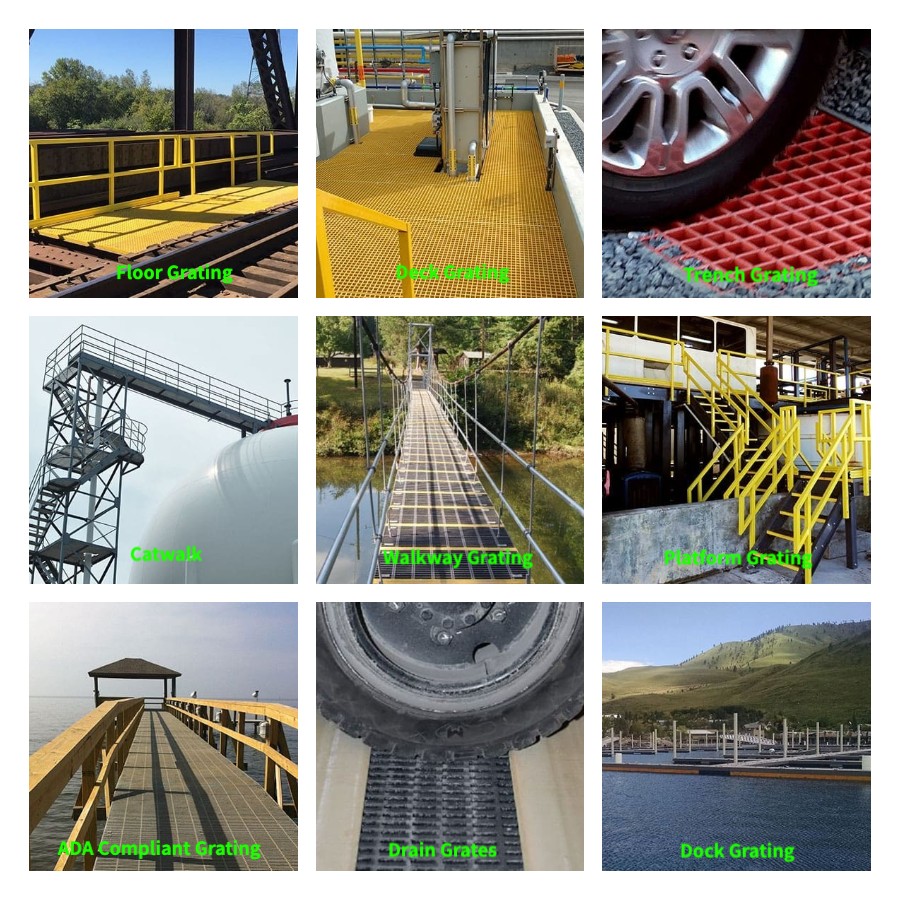

Application

FRP gratings are usually used as floor grating, marina walkway, roof walkway, catwalk grating, work platforms, offshore platforms, decks, stair treads, fencing, tree guard, drain channel cover, ditch covers, etc.

And they are widely used in petroleum, water conservancy, textile printing and dyeing, food processing, electronics industry, sewage treatment, shipbuilding, civil construction, power engineering, power substations, and chemical industries.

To find the specification and more detailed properties of our FRP grating, please feel free to contact us.

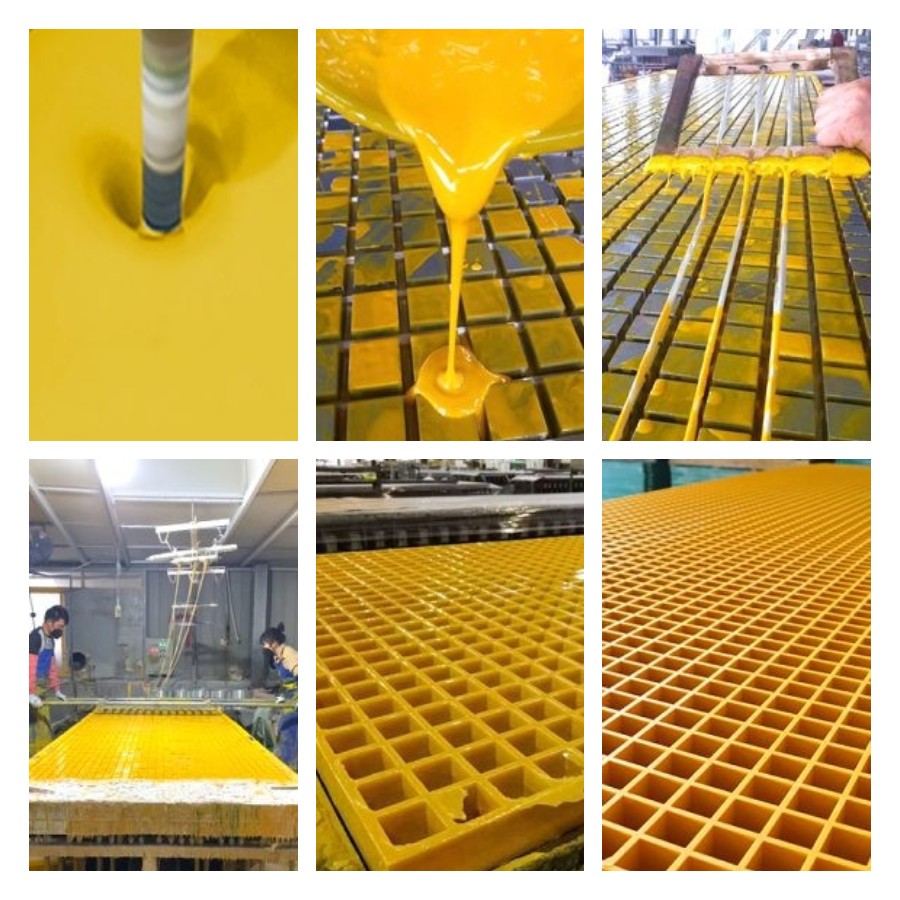

FRP molded grating equipment

Fiberglass gratings equipment is mainly composed of four parts: the molded grating device, heating system, cooling system and ancillary equipment.

FRP molded grating devices can be adjusted according to product size and different specifications, but little change in the overall structure. It is composed of the following components: the cavity part, the roof system, cooling and heating system and basic part.

Heating is necessary to guarantee gratings shape. Unsaturated resin only cures polymerization under certain temperature and humidity, at the same time heating system can ensure the quality of the gratings. The system is composed of a heating pipe and connecting components, and the heating device consists of the external heating curing system.

Cooling is necessary to ensure the production of high speed, specific principles and similar to the heating system.

The heating system consists of heater, temperature controller, rehydration, pipeline, valve and pump system. The function of heating system is to provide heat

Cooling system consists of pipelines, valve and other components, the main role of equipment is to take the heat energy.

FRP Molded Grating Production Process

- Mixing the rawmaterials

- Casting material

- Pull fiberglass

- Press mould

- Cooling and releasedfrom mold

- Polishing and washing

Please Feel Free To Contact Me

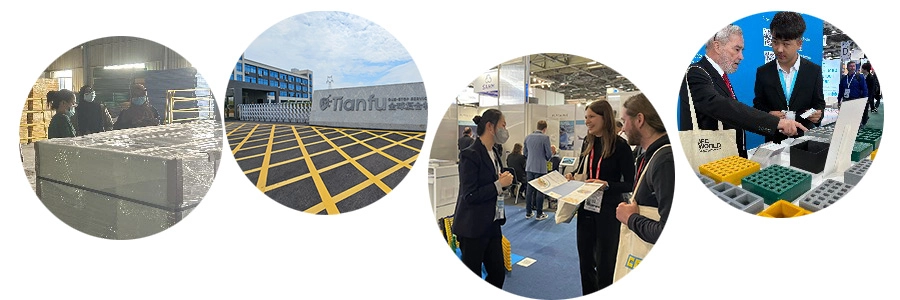

- Welcome to visit our factory

- Free Sample FRP Molded Grating Supplier

- JEC World 2024 - International Trade Administration

- Warehouse has sufficient supply

You can get quotation, technical advice and help around our fiberglass products.Thank you for submitting the inquiry, we will contact you soon!

25MM FRP Molded Grating

Series :

Main Products >application

Chemical industry, paper industry, power plant, sewage treatment plant, offshore drilling platform, food processing plants melting.Refineries, mines, salt farms, nuclear power plants.battery plants and so on. Can be used as: pedestrian walkway, bridge plank, work lndustrial floor, operating platform, trench cover, pallet, guardrail, fence, shelf, isolation belt, green walkway, Floor step,etc.

Brand name :

TFcomposite

Product name :

FRP Molded Grating

Technique :

Molded

Material :

Unsaturated polyester resin and glass fiber roving

MOQ :

50pcs

FAQ

Q :

Are you a factory that produces FRP molded grating?

A :

Yes, we are a professional manufacturer of FRP gratings, we have covers an area of nearly 15,000 square meters, has nearly 120 employees, equipped more than 100 sets of standard grating molds, 15 automatic pultrusion lines.

Q :

How to choose if there is a requirement for the load bearing of the FRP grating?

A :

It depends on the application where you buy the grating, whether it is a walkway or a passing vehicle.

Q :

We are a decoration company, can we buy your FRP grating as decorations?

A :

Yes, our colors can be customized according to customer needs, we can make all the colors on the Raul color card.

Q :

Do you guarantee after-sales service when purchasing your FRP grating?

A :

Yes, we can guarantee two years of after-sales.

Other related products