Alkali-resistant glass fiber mesh cloth is based on glass fiber woven fabric, using medium-free glass fiber yarn (mainly composed of silicate) through a special organizational structure - leno weaving, and then coated with acrylic Emulsion drying heat setting treatment, with good alkali resistance, flexibility and high tensile strength in warp and weft.

Product performance introduction

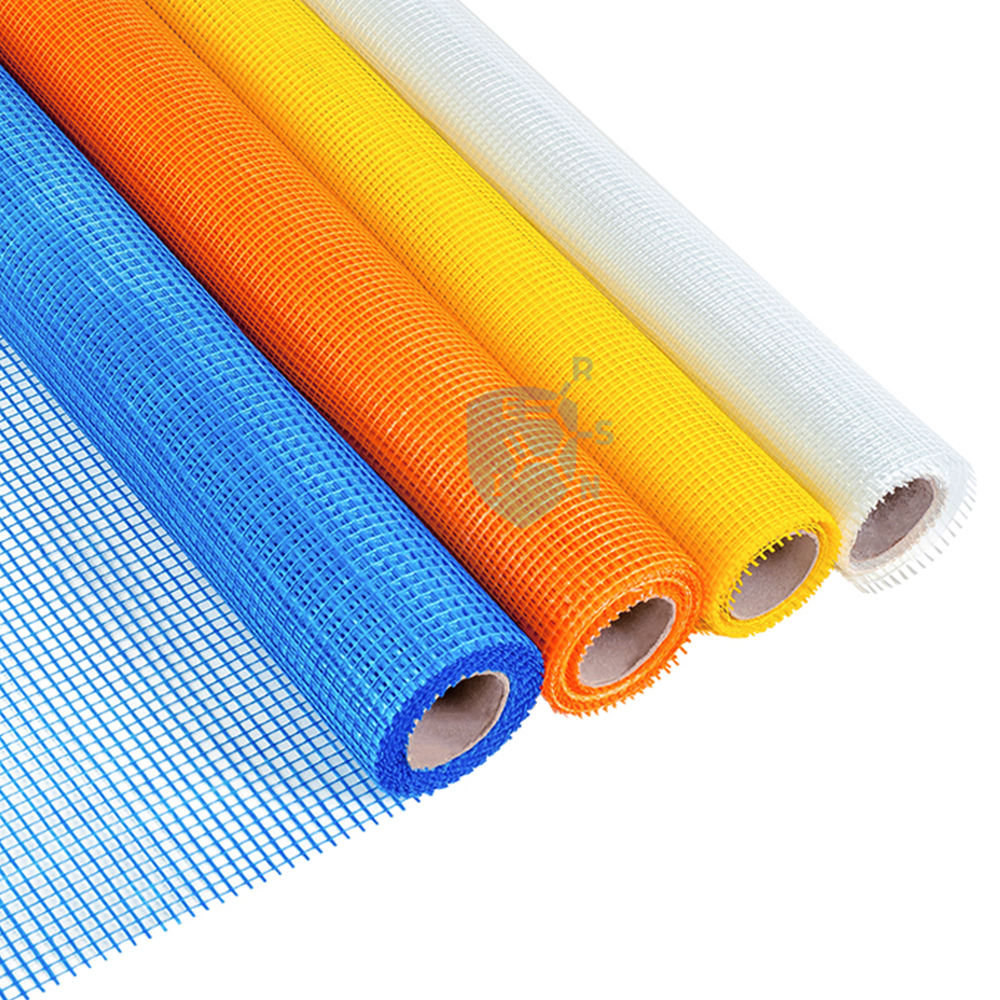

300 GSM 3*3*6 Fiberglass Mesh Description

Alkali Resistant Glass Fiber Mesh is fiberglass leno fabric as the substrate, the anti-emulsion polymer coating after immersion, which has good alkali resistance, flexibility and strong tensile strength, it can be widely used in exterior insulation finishing system (EIFS), roofing system, marble, etc.

The 300 GSM 336 Fiberglass Mesh is an ultra-heavy-duty, high-performance fiberglass mesh fabric designed for the most demanding applications that require exceptional strength, durability, and dimensional stability. This product features a record-breaking areal weight of 300 grams per square meter (GSM) and a unique 336 mesh size, making it the ultimate choice for industrial, commercial, and architectural applications where the highest-performance properties are critical.

Key Features:

- High-Quality Fiberglass Yarns: The 300 GSM 336 Fiberglass Mesh is made from the highest-quality fiberglass yarns, which provide exceptional mechanical properties, including tensile strength, impact resistance, and durability.

- Unique 336 Mesh Size: The 336 mesh size features a unique weave pattern, which provides outstanding dimensional stability, durability, and resistance to distortion.

- Unmatched Areal Weight: The areal weight of 300 GSM makes it the heaviest-duty fiberglass mesh available, offering an exceptional balance between strength, durability, and weight.

- Advanced Alkali-Resistant Coating: The fiberglass mesh is treated with an advanced alkali-resistant coating, which provides exceptional durability and resistance to corrosion.

- High-Temperature Resistance: The fiberglass mesh is capable of withstanding extremely high temperatures, making it suitable for applications where thermal stability is critical.

- Integrated Reinforcement: The 300 GSM 336 Fiberglass Mesh features integrated reinforcement, providing additional strength and durability to the fabric.

Technical Specifications:

- Areal weight: 300 GSM

- Mesh size: 336 (3 threads/cm x 3 threads/cm x 6 threads/cm)

- Yarn diameter: 1.4-1.6 mm

- Material: Fiberglass

- Weave pattern: Unique 336 weave

- Thread count: 3 threads/cm x 3 threads/cm x 6 threads/cm

- Breaking strength: ≥ 3200 N

- Elastic modulus: ≥ 200 GPa

- Elongation at break: ≥ 9.0%

- Thermal stability: up to 700°C

Benefits:

- Unmatched Strength and Durability: The 300 GSM 336 Fiberglass Mesh provides the highest mechanical properties, making it the ultimate choice for the most demanding applications.

- Exceptional Dimensional Stability: The unique 336 mesh size and record-breaking areal weight provide outstanding dimensional stability, reducing distortion and ensuring precise fabric performance.

- Advanced High-Temperature Resistance: The fiberglass mesh is capable of withstanding extremely high temperatures, making it suitable for applications where thermal stability is critical.

- Integrated Reinforcement: The integrated reinforcement provides additional strength and durability to the fabric, making it ideal for applications where ultimate performance is required.

- Cost-Effective: The 300 GSM 336 Fiberglass Mesh is a premium solution that offers an exceptional balance between performance and price.

Applications:

- Aerospace: Critical aircraft components, satellite components, and other applications where ultra-high-performance properties and thermal stability are critical.

- High-Performance Automotive: Luxury car bodywork, engine compartments, and other applications where exceptional strength and durability are required.

- Industrial: Extreme industrial applications, such as chemical plant construction, where ultra-high durability and high-temperature resistance are required.

- Architectural: High-performance building facades, roofing, and wall cladding, where exceptional strength and durability are required.

- Marine: High-performance boat hulls, decks, and other applications where exceptional strength, durability, and thermal stability are required.

Comparison to 250 GSM 336 Fiberglass Mesh:

- Increased Areal Weight: The 300 GSM 336 Fiberglass Mesh has a higher areal weight, making it more suitable for applications where higher strength and durability are required.

- Improved High-Temperature Resistance: The 300 GSM 336 Fiberglass Mesh has improved high-temperature resistance, making it more suitable for applications where thermal stability is critical.

- Enhanced Dimensional Stability: The 300 GSM 336 Fiberglass Mesh has enhanced dimensional stability, reducing distortion and ensuring precise fabric performance.

- Integrated Reinforcement: The 300 GSM 336 Fiberglass Mesh features integrated reinforcement, providing additional strength and durability to the fabric.

Specification

The production and quality control of the products are strictly carried out in accordance with Iso9001:2000.

| Specification | Glue content | Tensile Strength(N/50mm) | Weaving Type | ||||

| Weight(g/m2) | Mesh count | Cell size | Warp Yarn(N) | Weft Yarn(N) | Position(N) | ||

| 300 | 5 | 3x3x6 | 14% | >=2500 | >=2900 | >=6.0 | leno |

| 250 | 5 | 3x3x6 | 14% | >=2200 | >=2300 | >=4.5 | leno |

| 160 | 6 | 4x4 | 14% | >=1400 | >=1700 | >=3.5 | leno |

| 145 | 5 | 5x5 | 14% | >=1200 | >=1450 | >=3.0 | leno |

| 125 | 5 | 5x5 | 14% | >=1200 | >=1250 | >=2.5 | leno |

| 110 | 2.5 | 10x10 | 16% | >=700 | >=650 | >=2.0 | leno |

| 100 | 5 | 5x5 |

15%

|

>=600

|

>=700

|

>=2.0

|

leno |

| 70 | 5 | 5x5 | 16% | >=600 |

>=700

|

>=1.5

|

leno

|

Fiberglass Mesh Roll Features

1.Good material:High-performance alkali-free glass fiber not only has the advantages of traditional glass,but also has technological break through in strength,modulus, corrosiveness, and high temperature resistance,which can meet market demand.

2.Multiple Use :Alkali-free non-twisted roving is a high-performance reinforcing material,Widely used in hand-lay-up and mechanical molding products,Such as ships,containers, airplane , car,furniture ,Sports facilities.

3.Product feature :

- Warp and weft roving alignecin a parallel and flat manner resulting in uniform tension.

- Densely aligned fibers, resulting in high dimensional stability and making handing easy.

- Good mold ability, fast and complete wet in resins, resulting in high productivity.

- Good transparency and high strength of composite products.

4.Brand Fiberglass :The products are sold to more than 30 provinces and cities in China and more than 100 countries and regions in the world.

Packaging & delivery

- Packaging Details:PVC bag or Shrink package as inner package, then loaded into Carton or Pallet

- Port:shanghai

- Lead time:

-

Quantity(kiloamperes) 1 - 3000 3001 - 10000 >10000 Lead time (days) 5 10 To be negotiated

300 GSM 3*3*6 Fiberglass Mesh

Series :

Proxy Products >application

EIFS(Exterior Insulation Finishing System), cement products, asphalt, marble/mosaic backing, partition board, Mgo board, Fireproof board, gypsum products, roof waterproofing, GRC

Brand name :

TF Composite

Product name :

600 gsm 3*3*6 Fiberglass Mesh

Material :

Fiberglass

FAQ

Q :

What's the MOQ?

A :

Usually 1 Ton

Q :

Package & Shipping.

A :

Normal package:carton(Incuded in the unite price) Special Packge: need to charge according the actual situation. Normal shipping :your nominated Freight forwarding.

Q :

What's your delivery time for production?

A :

If we have stock , can delivery in 7 days ; if without the stock, need 7~15 days !

Other related products