Our GRP handrail system often used in a GRP handrail or guardrail to continue the middle rail on a 90° corner or connect vertical posts to the top rail, or to join the midrail to the end post.

Product performance introduction

|

|

The GRP external Swivel is a versatile in-line swivel fitting, often used where angles vary on slops, steps and landings. |

|

The GRP 116 Mid Corner is a 90° corner joint, often used in a GRP handrail or guardrail to continue the middle rail on a 90° corner, but can also be used to build rectangular or square structures. The upright passes vertically through the GRP fitting. Often used with the GRP-128 Top Corner. |

|

|

The GRP 101 Short Tee is a 90° tee connection, typically used in a GRP handrail to connect vertical posts to the top rail, or to join the midrail to the end post. The tube cannot be joined within the top of the fitting-the GRP-104 Long Tee can be used as an alternative if this is required. |

|

The GRP Fitting 119 Midrail Cross is a 90° joint, often used to join the middle rail to an intermediate upright post in a GRP handrail or guardrail. The upright passes vertically through the GRP fitting. |

|

|

The GRP 104 Long Tee is a 90° tee connection, typically used to connect vertical posts to the top rail of a GRP handrail. The GRP -104 can be used where two lengths of tube need to be joined within the top of the fitting. |

|

The GRP 125 fitting is a 90° elbow, often used in a GRP handrail or guardrail to connect the top rail to the upright post at the end of a run. |

|

|

The GRP 129 is a 30° tee fitting, often used in a staircase GRP handrail or guardrail. |

|

The 128 Top Corner fitting is a 3-way. 90° elbow, typically used to join an upright post to the top rail of a GRP handrail on a 90º corner. Often used with the GRP-116 Mid Corner. |

|

|

The GRP 130 is a 30° Cross, often used to connect the midrail to intermediate posts in a staircase GRP handrail. |

|

The GRP 116 Mid Corner is a 90° corner joint, often used in a GRP handrail or guardrail to continue the middle rail on a 90° corner, but can also be used to build rectangular or square structures. The upright passes vertically through the GRP fitting. Often used with the GRP-128 Top Corner. |

|

|

The GRP 132 Base Plate is a base flange with four fixing holes, used to fix down the upright posts in a handrail or guardrail. |

|

The GRP 173 Single Swivel is a versatile swivel fitting, used where angles vary on slopes, steps and landings. |

|

|

The 145 Wall Socket is a GRP Fitting designed for side fixing GRP handrails or guardrails to walls, ramps and steps. |  |

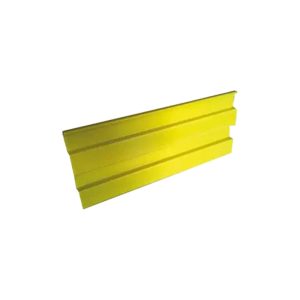

Our GRP Kick plate is 100mm wide, with a 5mm wall. It is stocked in 6m lengths but can be cut to length if required. |

Made in China glass reinforced plastic (GRP),TFcomposite’s GRP handrail system offers key benefits over steel that explain why you’ll see GRP handrailing everywhere from water treatment works to the rail industry.

Once you’ve completed the simple installation – requiring only a stainless steel bolt to clamp together the fittings – your GRP handrail will provide protection for years to come, even in the most challenging environments.

A GRP (Glass Reinforced Plastic) handrail system typically consists of various modular components that make assembly and customization easy. Here are the main parts of a GRP handrail system:

1. Handrail Tube

- Description: The main structural element, usually in round or square profile.

- Dimensions: Varies based on application, with common diameters around 30–50mm.

- Features: UV-stable, corrosion-resistant, and often textured for grip.

2. Top Rails

- Description: Top handrail section that provides a comfortable grip and ensures safety.

- Mounting Style: Typically mounted on posts using brackets or connectors.

3. Posts / Uprights

- Description: Vertical supports that anchor the handrail system and connect it to the ground or structure.

- Spacing: Typically spaced around 1–1.5 meters apart, depending on load requirements.

- Features: Often come with a base plate for securing to surfaces.

4. Kick Plate / Toe Board

- Description: A horizontal plate at the bottom of the system that prevents objects or debris from falling off raised platforms.

- Height: Generally 100–150mm high, depending on safety standards.

5. Mid Rails

- Description: Additional horizontal rails placed between the top rail and the kick plate for added safety.

- Spacing: Typically spaced to meet safety standards, such as OSHA or ANSI.

6. Elbows and Corner Connectors

- Description: Fittings that allow the handrail system to form corners, bends, or changes in direction.

- Types: 90° elbows, 45° elbows, and adjustable connectors for custom angles.

- Material: Made from GRP or corrosion-resistant metal for durability.

7. Tees and Cross Connectors

- Description: Connectors used to join multiple handrail sections or create T- or cross-junctions.

- Usage: Allows for the intersection of handrails at right angles or multiple directions.

8. Base Plates

- Description: Plates at the bottom of posts that are bolted or anchored to a surface.

- Installation: Available as surface-mounted or embedded options.

- Material: Often galvanized steel or GRP, depending on environment and load requirements.

9. Wall Brackets

- Description: Mounting brackets that attach the handrail to walls or other surfaces.

- Application: Used for wall-mounted handrails, particularly on stairs and ramps.

10. End Caps

- Description: Caps placed at the end of handrail tubes to seal and protect the tube from moisture and debris.

- Material: GRP or rubberized plastic for a secure, durable seal.

- Additional Feature: Improves the aesthetics and prevents accidental injuries from sharp edges.

11. Base Plate Covers

- Description: Protective covers that hide mounting hardware and provide a clean look.

- Material: GRP or plastic to match the handrail system.

12. Anti-Slip Surface Coatings

- Description: Often added to the top rail or kick plate, providing extra grip for safety.

- Material: Coatings are typically embedded in the GRP during manufacturing or added as an overlay.

13. Expansion Joints

- Description: Allow for expansion and contraction due to temperature changes without damaging the system.

- Application: Used in longer runs of railing, especially in outdoor installations.

14. Fasteners and Fixings

- Description: Nuts, bolts, and screws that secure the components together.

- Material: Typically stainless steel or GRP for corrosion resistance.

Application:

GRP handrail system fiberglass corrosion-resistant non-slip eco-friendly

Series :

Main Products >application

Our GRP handrail system is widely used in GRP handrail and guardrail's multi-drop-and-continue cross-connection.

Brand name :

TFcomposite

Color :

yellow or grey

FAQ

Q :

What size and length does the GRP handrail tube come in?

A :

The GRP tube is only produced in 50mm o/d (outside diameter) and is stocked in 5m lengths. We can cut the tube down to length if needed.

Q :

How are the fittings fixed to the tube?

A :

Fittings for GRP handrails are supplied as two identical halves which simply clamp together around the tubing. These need to be drilled onsite using a standard 9mm diameter HSS drill bit (supplied with your order) and bolted together with the special stainless steel rivnut fixings provided. The bolts are then inserted and tightened using a pozi 3 driver, the knurled rivnut fixing will hold in place whilst the bolt is tightened. These fixings provide a flush finish with no protruding bolt heads.

Q :

What colours are available for GRP handrail systems?

A :

We stock the tube and fittings in yellow – for high visibility – or grey.

Other related products