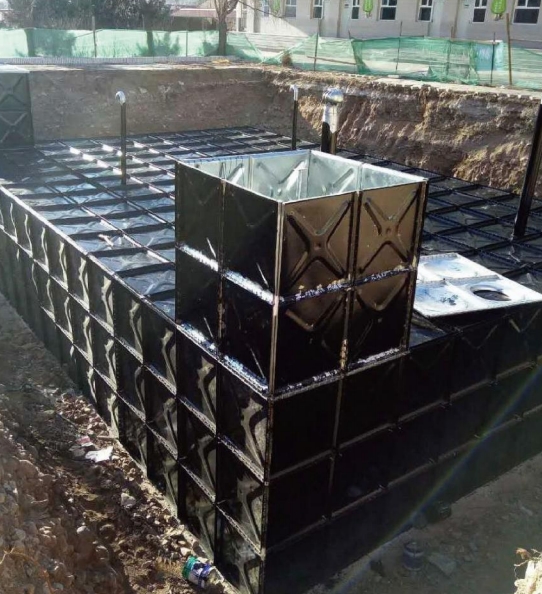

GRP Modular Water Tanks are made from a composite material that combines glass fibers and resin, resulting in a strong, lightweight, and corrosion-resistant water storage solution. They are designed for easy assembly and are ideal for both small and large-scale water storage needs.

Product performance introduction

GRP Modular Water Tanks

-

Material Composition

- Glass Reinforced Plastic: A composite material that provides excellent strength-to-weight ratio and resistance to corrosion.

- UV Resistance: GRP tanks are resistant to UV radiation, which helps prevent degradation over time.

-

Modular Design

- Interlocking Panels: Constructed from modular panels that can be easily assembled on-site, allowing for flexibility in size and configuration.

- Customizable Sizes: Available in various dimensions, making it easy to create a tank that fits specific space requirements.

-

Durability

- Corrosion Resistance: GRP does not rust or corrode, making it suitable for harsh environments and long-term water storage.

- Impact Resistance: Capable of withstanding physical impacts without compromising structural integrity.

-

Lightweight

- Ease of Transport and Installation: The lightweight nature of GRP makes it easier to transport and install compared to traditional materials like concrete or steel.

-

Safety and Hygiene

- Non-Toxic: Safe for storing drinking water, with no leaching of harmful substances.

- Smooth Interior Surface: Reduces bacterial growth and makes cleaning easier.

-

Low Maintenance

- Minimal Upkeep Required: GRP tanks are designed for long-term use with little maintenance needed.

-

Thermal Insulation

- Temperature Control: GRP provides good thermal insulation, helping maintain water temperature and reducing energy costs for heating or cooling.

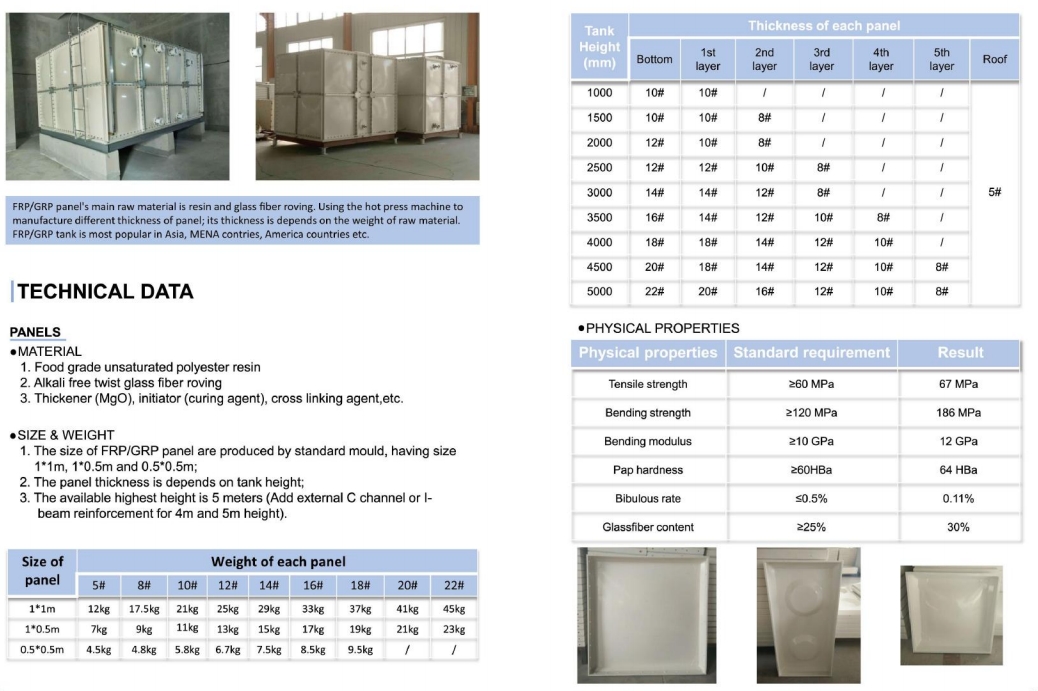

Technical Specifications

- Panel Thickness: Typically ranges from 5mm to 15mm, depending on tank size and specific requirements.

- Capacity: Available in a wide range of capacities, from a few hundred liters to several hundred thousand liters.

- Finish Options: Often available in different colors and surface finishes to suit aesthetic preferences and environmental conditions.

Applications

- Residential: Suitable for domestic water supply, rainwater harvesting, and emergency water storage.

- Commercial: Ideal for hotels, restaurants, and commercial buildings where reliable water storage is needed.

- Industrial: Used in various industries for process water, chemical storage, and fire protection systems.

Advantages

- Cost-Effective: GRP tanks typically offer a more affordable solution compared to traditional materials, especially for larger capacities.

- Quick Installation: The modular design allows for rapid assembly and installation, minimizing downtime.

- Versatile Use: Can be used for both potable and non-potable water storage, making them highly adaptable.

Warranty and Support

- Warranty: Most manufacturers offer warranties ranging from 5 to 15 years, depending on the tank model and usage conditions.

- Customer Support: Comprehensive support is usually available for inquiries, installation guidance, and maintenance advice.

Conclusion

GRP Modular Water Tanks provide a versatile, durable, and cost-effective solution for water storage across a wide range of applications. Their lightweight and corrosion-resistant properties make them ideal for both residential and industrial use. Whether for drinking water, irrigation, or industrial processes, GRP tanks deliver reliable performance and long-term value.

GRP Modular Water Tanks

Series :

Proxy Products >application

water storage in municipalities, industrial users, agriculture, aquaculture, reservoirs, hotels, hospitals, offices, private homes and other building complexes

Brand name :

TFcomposite

Product name :

SMC Water Tank

Material :

Hot pressed GRP panel (also call FRP, SMC or Composite)

Size Of Panels :

0.5 x 0.5m | 1.0 x1.0m | 1.0 x 1.5m

Color :

Any color you want

FAQ

Q :

What is the capacity of SMC water tank?

A :

SMC Panel Overhead Tank, Capacity: 1³-1000m³

Other related products