Fiberglass stair treads and stair covers are an essential complement to molded and pultruded grating installations.

Product performance introduction

Fiberglass stair treads are a durable, lightweight, and cost-effective solution for staircases in various industrial, commercial, and residential applications. Designed to provide exceptional safety and longevity, these treads combine advanced materials and innovative engineering to meet the demands of diverse environments. This product is ideal for locations where safety, resistance to environmental elements, and long-term performance are priorities.

1. Material Composition

Fiberglass stair treads are constructed using fiberglass-reinforced plastic (FRP), a composite material known for its outstanding strength-to-weight ratio. The main components include:

- Fiberglass: Provides structural reinforcement and tensile strength.

- Resin Systems: Typically made from polyester, vinyl ester, or epoxy resins, offering resistance to moisture, chemicals, UV rays, and other environmental factors.

- Surface Grit: Often includes a silicon carbide or quartz grit embedded in the surface for enhanced slip resistance.

- Optional Coatings: UV-stabilized or fire-retardant coatings can be added to improve durability and safety.

2. Key Features

- Slip Resistance: Fiberglass stair treads feature an anti-slip surface to prevent accidents in wet, oily, or otherwise hazardous environments. The embedded grit surface ensures maximum traction, even in challenging conditions.

- Corrosion Resistance: Unlike metal or wood, fiberglass does not corrode, warp, or decay, making it suitable for harsh environments such as chemical plants, marine locations, or wastewater treatment facilities.

- Lightweight: Fiberglass is significantly lighter than traditional materials like steel or concrete, simplifying installation and reducing structural load.

- Durability: High resistance to wear and tear, ensuring longevity even under heavy foot traffic.

- Low Maintenance: Requires minimal upkeep due to its inherent resistance to stains, chemicals, and UV exposure.

3. Applications

Fiberglass stair treads are versatile and can be used in a variety of industries and settings, including:

- Industrial Facilities: Ideal for factories, chemical plants, oil refineries, and mining operations where safety and durability are critical.

- Marine and Offshore: Suitable for docks, ship decks, and offshore platforms due to their resistance to saltwater and corrosive conditions.

- Public Infrastructure: Frequently used in bridges, railways, and pedestrian overpasses for their durability and slip-resistant properties.

- Commercial Buildings: Office buildings, parking structures, and shopping centers benefit from their low maintenance and aesthetic versatility.

- Residential: Fiberglass stair treads are also suitable for outdoor decks, pools, and gardens.

4. Types of Fiberglass Stair Treads

-

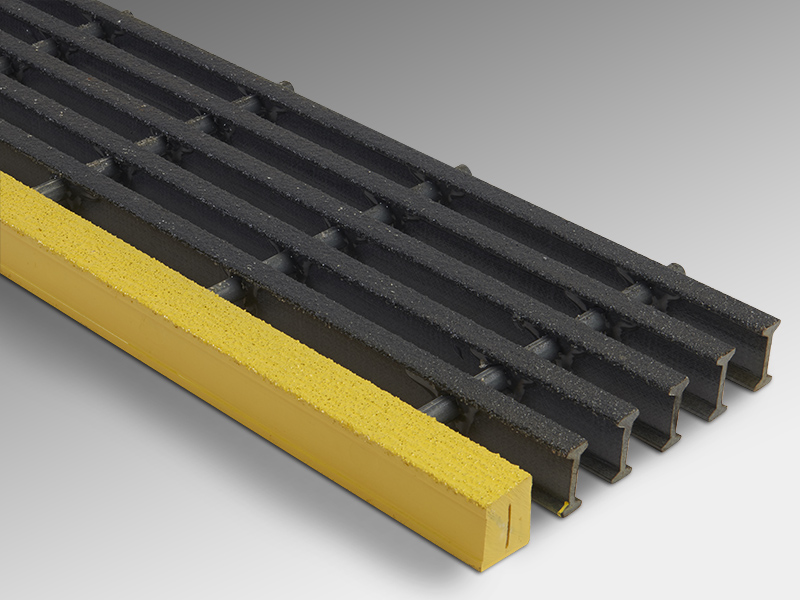

Molded Fiberglass Treads:

- Manufactured by molding fiberglass into a grid-like structure.

- Offers excellent load-bearing capabilities and is ideal for high-traffic areas.

-

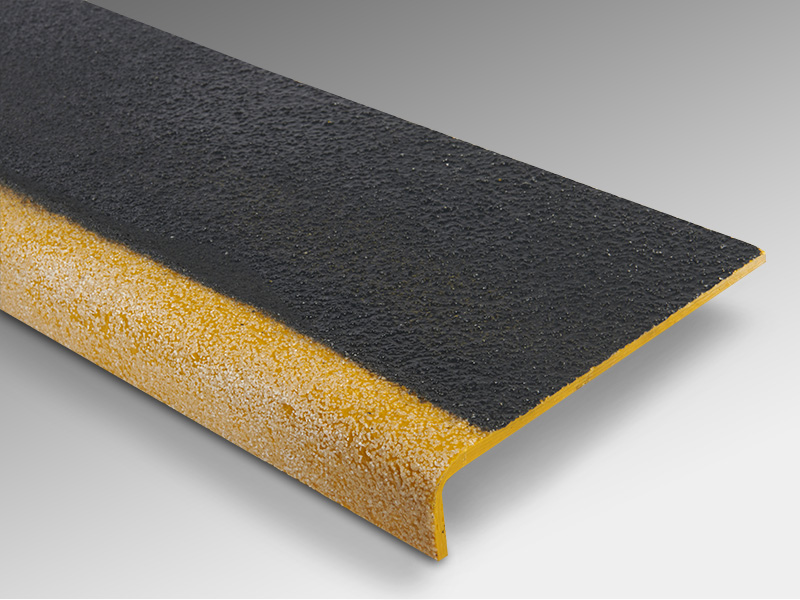

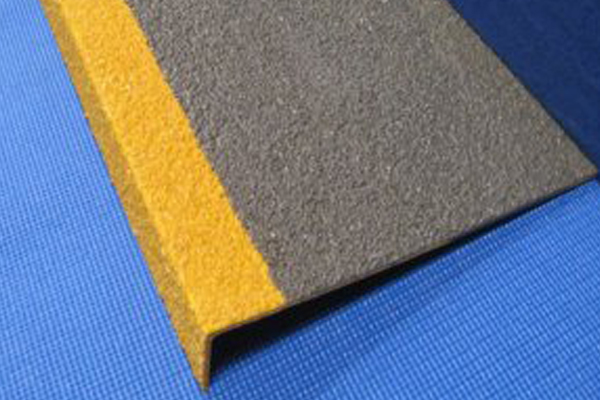

Pultruded Fiberglass Treads:

- Produced using a continuous pultrusion process, resulting in uniform and high-strength panels.

- Best suited for environments requiring long spans and heavy-duty applications.

-

Covered Stair Treads:

- Feature a solid top surface for better aesthetic appeal and additional safety.

- Often used in areas where cleanliness is essential.

-

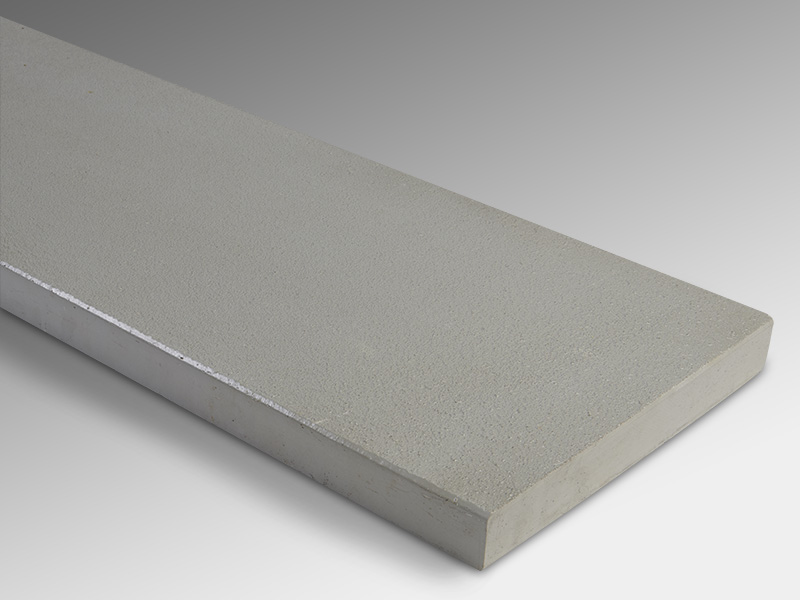

Customized Treads:

- Tailored to specific needs, including custom sizes, colors, and surface finishes.

5. Technical Specifications

- Thickness: Typically ranges from 25 mm (1 inch) to 38 mm (1.5 inches), depending on the application.

- Load Capacity: Designed to handle heavy loads, often exceeding 500 kg/m² (100 lbs/ft²).

- Slip Resistance: Achieves a high coefficient of friction (COF), often exceeding 0.6 under both wet and dry conditions.

- Fire Resistance: Meets international fire safety standards, such as ASTM E84 for flame spread and smoke development.

- Temperature Range: Operates effectively in temperatures from -40°C to 120°C (-40°F to 248°F).

- Color Options: Available in standard colors like yellow, gray, and green, with custom options on request.

- UV Protection: Optional UV-resistant coating to prevent discoloration and degradation from sunlight.

6. Advantages Over Traditional Materials

-

Steel:

- Fiberglass does not rust, eliminating the need for regular painting or coating.

- Lightweight and easier to install.

-

Wood:

- Resistant to moisture, pests, and rot, making it a better choice for outdoor and humid environments.

-

Concrete:

- Requires less maintenance and is not prone to cracking or spalling.

7. Installation Process

Installing fiberglass stair treads is straightforward and requires minimal tools and labor. The steps typically involve:

- Preparation: Cleaning the installation site and ensuring a level surface.

- Measurement and Cutting: Cutting treads to the required dimensions using standard power tools equipped with diamond blades.

- Fixing: Securing the treads using adhesive, bolts, or clips. Non-penetrating clips are available for applications where drilling into the substrate is not feasible.

- Sealing: Applying sealants or coatings for additional protection, if required.

8. Environmental Benefits

Fiberglass stair treads are eco-friendly due to their long lifespan and low maintenance requirements. Additionally, they reduce the need for harsh chemicals typically used for cleaning and maintenance in other materials.

9. Certifications and Standards

Most high-quality fiberglass stair treads comply with international safety and quality standards, such as:

- OSHA (Occupational Safety and Health Administration) for workplace safety.

- ANSI (American National Standards Institute) for slip resistance.

- ISO 9001 for manufacturing quality.

10. Maintenance Guidelines

To ensure the longevity and performance of fiberglass stair treads:

- Clean regularly with mild soap and water to remove dirt and debris.

- Inspect for damages or loose fittings periodically.

- Avoid using abrasive cleaners that may degrade the surface grit.

11. Frequently Asked Questions (FAQs)

-

Are fiberglass stair treads safe for outdoor use?

Yes, they are highly resistant to UV rays, moisture, and temperature fluctuations, making them ideal for outdoor environments. -

How do fiberglass treads compare in cost to metal or wood?

While the initial cost may be higher, the low maintenance and long lifespan of fiberglass result in significant cost savings over time. -

Can they be customized?

Yes, most manufacturers offer customization options for dimensions, colors, and surface finishes. -

What is the expected lifespan?

Fiberglass stair treads can last 20-30 years or more, depending on the usage and environment.

Conclusion

Fiberglass stair treads are a robust, versatile, and reliable solution for staircases in various applications. Their superior durability, safety features, and resistance to environmental elements make them a worthwhile investment for both temporary and permanent installations. Whether in an industrial plant, a marine platform, or a residential backyard, fiberglass stair treads offer unparalleled performance and peace of mind.

Weatherproof Molded FRP Stair Treads for Outdoor Use

Series :

Fiberglass Stair Treads >application

FAQ

Other related products