Product performance introduction

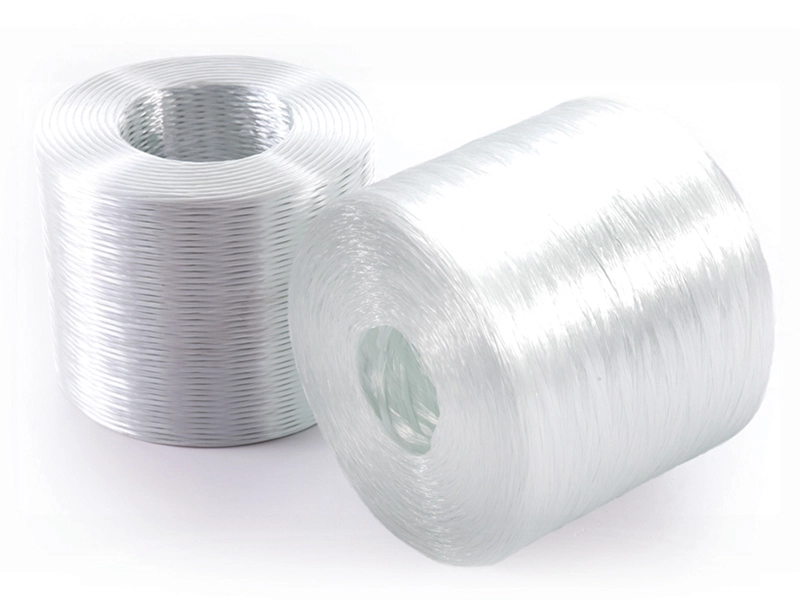

Unlike conventional twisted yarns, untwisted rovings maintain their linear bundle structure throughout processing. This unique construction results in higher fabric strength, improved impregnation properties, and better dimensional stability. As an essential raw material for woven and stitched fabrics, untwisted roving is designed to deliver optimized weaving performance and high-quality composite properties.

2. Product Definition and Structure

Untwisted roving is a bundle of continuous glass filaments grouped together without twisting. Each roving consists of thousands of filaments (typically 2400, 4800, or 9600 tex), which are held together by a binding agent or sizing. The absence of twist allows the roving to lay flat, improving fabric uniformity and enhancing resin wet-out capabilities.

Key Characteristics:

-

Continuous filaments of E-glass, ECR-glass, or high-performance specialty glass

-

No twist – filaments remain parallel and flat

-

Custom tex values (e.g., 300, 600, 1200, 2400, 4800, 9600)

-

Silane-based sizing compatible with various resin systems (e.g., epoxy, polyester, vinyl ester)

-

Excellent weaving compatibility

3. Manufacturing Process

The production of untwisted roving involves several critical steps:

-

Glass Melting: High-purity raw materials (silica, alumina, boron oxide) are melted at temperatures exceeding 1400°C in a platinum-rhodium bushing.

-

Fiberization: The molten glass is extruded through small orifices in the bushing to form continuous filaments, typically 9–13 microns in diameter.

-

Sizing Application: A chemical sizing is sprayed onto the filaments immediately after extrusion. This sizing improves bundling, enhances resin compatibility, and minimizes fiber abrasion.

-

Gathering: The filaments are collected into a bundle (roving) using gathering shoes or combs, ensuring the fibers are aligned without twisting.

-

Winding: The untwisted roving is wound onto cylindrical packages or cheeses suitable for warping and weaving machines.

4. Applications

Untwisted roving is widely used across industries due to its superior performance characteristics. Major applications include:

4.1 Woven Roving Fabric

-

Used for structural reinforcement in hand lay-up and RTM processes

-

High strength-to-weight ratio

-

Common in boat hulls, tanks, and panels

4.2 Multiaxial Fabrics (Stitched or Non-Crimp)

-

Produced by combining rovings in multiple orientations (e.g., ±45°, 0°, 90°)

-

Enhanced mechanical properties

-

Popular in wind turbine blades, automotive body panels, and aerospace composites

4.3 Pultrusion and Filament Winding

-

While twisted roving is traditionally used, untwisted rovings may be used for flat profiles or wide reinforcements

4.4 Textile Industry

-

As warp and weft yarns for industrial textiles and fire-resistant fabrics

5. Advantages

Untwisted rovings offer numerous advantages over twisted rovings and conventional yarns:

| Advantage | Description |

|---|---|

| High Fabric Strength | Parallel alignment of fibers ensures better load distribution and increased tensile strength |

| Improved Impregnation | Reduced capillary resistance allows resins to penetrate evenly and quickly |

| Dimensional Stability | No twist means better fabric flatness and reduced yarn distortion |

| Process Efficiency | Suitable for high-speed weaving without excessive fiber breakage |

| Custom Compatibility | Tailored sizings ensure compatibility with a variety of resins and processes |

6. Types of Untwisted Roving

| Type | Tex (g/km) | Filament Diameter (μm) | Typical Use |

|---|---|---|---|

| E-glass 300 tex | 300 | 9 | Lightweight fabrics |

| E-glass 1200 tex | 1200 | 13 | Balanced woven roving |

| E-glass 2400 tex | 2400 | 13 | Heavy woven fabrics |

| ECR-glass 4800 tex | 4800 | 17 | Multiaxial fabrics |

| S-glass | Custom | Custom | High-performance aerospace fabrics |

7. Packaging and Storage

7.1 Packaging

-

Roll/cheese weight: 15–25 kg (customizable)

-

Inner diameter: 76 mm or 152 mm

-

Outer diameter: up to 280 mm

-

Packaging type: Palletized or boxed, shrink-wrapped, and optionally nitrogen-purged

7.2 Storage Recommendations

-

Store in a cool, dry place away from direct sunlight and high humidity

-

Recommended temperature: 15–35°C

-

Relative humidity: ≤75%

-

Avoid stacking more than 3 pallets high

8. Technical Considerations in Weaving

The performance of untwisted roving in weaving is dependent on several factors:

-

Weaving Loom Compatibility: Must be suitable for warp insertion and tension control

-

Warp Strength: Rovings must resist tension and abrasion during weaving

-

Size Uniformity: Consistent roving diameter and tex are crucial for fabric quality

-

Weave Density: Higher tex values result in fewer yarns per square meter but increase fabric thickness

9. Technical Data Sheet (TDS)

Below is a sample TDS for a standard 2400 tex E-glass untwisted roving for weaving.

Technical Data Sheet

Product Name: Untwisted Roving for Weaving – 2400 tex

Glass Type: E-glass

Product Code: UWR-E2400

Date: April 2025

1. General Properties

| Property | Unit | Value |

|---|---|---|

| Linear Density | tex | 2400 ± 5% |

| Filament Diameter | µm | 13 ± 1 |

| Moisture Content | % | < 0.10 |

| Loss on Ignition (LOI) | % | 1.0 ± 0.2 |

| Tensile Strength | N/tex | ≥ 0.30 |

| Sizing Type | – | Silane-based (multi-compatible) |

| Resin Compatibility | – | Polyester, Vinyl Ester, Epoxy |

| Yarn Twist | – | Zero (untwisted) |

2. Performance Parameters

| Parameter | Test Method | Result |

|---|---|---|

| Bundle Integrity | ASTM D578 | Excellent |

| Abrasion Resistance | Internal Method | High |

| Weavability | Internal Test | Excellent |

| Impregnation Rate | ASTM D3533 | ≤ 30 seconds |

| Tensile Modulus | ASTM D2343 | 73 GPa |

| Elongation at Break | ASTM D2343 | 4.8% |

3. Packaging

-

Form: Cylindrical cheese on paper core

-

Weight per roll: ~20 kg

-

Rolls per pallet: 48

-

Pallet size: 1150 × 1150 × 1000 mm

-

Gross weight per pallet: ~960 kg

4. Shelf Life

-

Recommended shelf life: 12 months from manufacturing date under controlled storage conditions.

10. Quality Assurance and Compliance

-

Standards Met:

-

ISO 9001: Quality Management System

-

ISO 14001: Environmental Management System

-

REACH and RoHS compliant

-

OEKO-TEX or fire-resistance certifications (upon request)

-

-

In-Process Controls:

-

Online tex monitoring

-

Tension consistency checks

-

Sizing distribution uniformity

-

-

Final Inspection:

-

Tex, moisture, and LOI analysis

-

Surface inspection

-

Yarn break test

-

11. Environmental Impact and Recycling

Untwisted roving made from E-glass and ECR-glass is considered non-toxic and inert. However, manufacturers are encouraged to:

-

Use water-based sizings to reduce VOC emissions.

-

Implement closed-loop recycling systems for offcuts and fabric waste.

-

Promote lightweighting in composites to reduce the carbon footprint in end-use applications (e.g., automotive and wind energy).

12. Conclusion

Untwisted roving for weaving is a cornerstone material for producing high-performance fiberglass fabrics and composites. With its outstanding mechanical properties, ease of processing, and compatibility with modern resin systems, it plays a vital role in lightweight structural applications. Whether used in multiaxial fabrics for wind blades or in woven roving for boat hulls, untwisted roving ensures performance, durability, and processing efficiency.

For manufacturers seeking to improve composite strength, reduce process times, and maintain high product consistency, untwisted roving is a proven and indispensable solution.

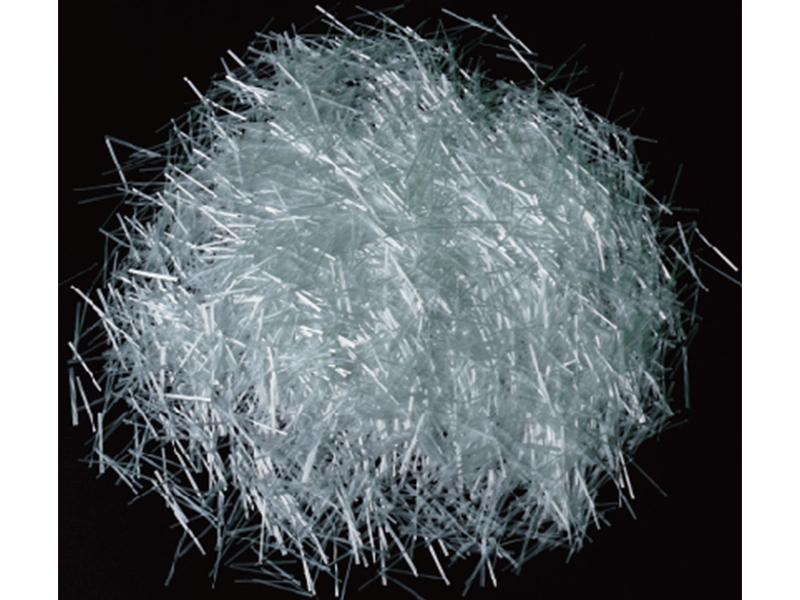

Untwisted roving for preforms

Series :

Fiberglass Assemble Roving >application

Automotive / Consumer Goods and Business Equipment / Sports and Leisure / Electrical and Electronics / Building and Construction / Infrastructure

Glass type :

E

Product Name :

Untwisted roving for preforms

FAQ

Q :

Are you a factory? Where are you located?

A :

We are manufacturer of FRP grating and pultruded profiles, trader of FRP yarn materials. We are the largest distributor of China Jushi Co. We also sell products of several FRP yarn manufacturers. We are in Anhui, China.

Q :

What information is recommended for the inquiry?

A :

1. Which tex you need? 2. What the application you use it for? Or the tecnologh, is weaving, pultrusion or winding? 3. How many quantity do you need? 4. What resin do you combined for? Polyester resin or epoxy resin? 5. Do you need FOB or CIF price, if CIF, please tell us your port.

Q :

What's the MOQ?

A :

Usually 1 Ton

Q :

Package & Shipping

A :

Normal package:carton(Incuded in the unite price) Special Packge: need to charge according the actual situation. Normal shipping :your nominated Freight forwarding.

Q :

When can I offer?

A :

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price pls call us or tell us in your email , so that we can reply you priority.

Q :

How do you charge the sample fees?

A :

If you need a samples from our stock, we can provide to you for free, but you need to pay the freight charge.If you need a special size, We will charge the sample making fee which is refundable when you place an order.

Q :

What's your delivery time for production?

A :

If we have stock , can delivery in 7 days ; if without the stock, need 7~15 days !

Other related products