مقدمة عن أداء المنتج

Given the corrosive and humid environment within sewage and drainage systems, FRP manhole covers provide superior longevity, zero rusting, and reliable load-bearing capacity even after decades of exposure to wastewater and gases like hydrogen sulfide (H₂S), methane, and ammonia.

⚙️ 2. Construction & Raw Materials

FRP sewage covers are manufactured using the صب الضغط technique, combining the following raw materials:

📌 Materials:

-

تعزيز الألياف الزجاجية: E-glass roving, chopped strand mat (CSM), woven roving

-

Resin Matrix: Isophthalic polyester, vinyl ester, or epoxy resins (based on application)

-

Fillers: Quartz powder, calcium carbonate, flame retardants, and pigments

-

Surface Layer: Anti-slip gelcoat or resin-rich anti-UV coating

-

المواد المضافة: UV stabilizers, colorants, flame retardants, anti-static agents

🛠️ Manufacturing Process:

-

Resin + fiber blend prepared.

-

Composite mix placed into preheated steel molds.

-

Material compressed at high pressure and temperature.

-

Demolded after curing, trimmed, and surface-treated.

📐 3. Available Sizes and Load Classes

FRP sewage manhole covers are available in:

| Shape | Size Range |

|---|---|

| Round | Ø300mm to Ø1200mm |

| مربع | 300x300mm to 1000x1000mm |

| Rectangular | Custom dimensions available |

🧱 Load Classes (EN 124):

| Class | سعة التحميل | طلب |

|---|---|---|

| A15 | 1.5 Ton | Pedestrian zones |

| B125 | 12.5 Ton | Pavements, sidewalks |

| C250 | 25 Ton | Urban streets, slow traffic |

| D400 | 40 Ton | Main roads, highways |

| E600 | 60 Ton | Docks, industrial yards |

| F900 | 90 Ton | Airports, heavy-duty applications |

🧪 4. Technical Data Sheet (TDS)

| ملكية | Value / Specification | معيار |

|---|---|---|

| اسم المنتج | FRP Sewage Manhole Cover | - |

| يكتب | Circular / Square / Hinged | - |

| عملية التصنيع | Compression Molding | - |

| تصنيف الحمل | A15 – F900 | EN 124 |

| مادة | Glass fiber + Polyester/Vinyl Ester resin | - |

| خيارات الألوان | Black, Grey, Green, Red, Yellow | Custom available |

| المعالجة السطحية | Anti-slip, UV-resistant gelcoat | - |

| قوة الانحناء | ≥ 150 MPa | ASTM D790 |

| قوة الضغط | ≥ 300 MPa | ISO 604 |

| Water Absorption | < 0.1% | ASTM D570 |

| مقاومة التأثير | ≥ 25 J | ISO 179 |

| Temperature Range | -40°C to +120°C | - |

| Electrical Resistance | >10⁶ MΩ | IEC 60093 |

| مقاومة الحريق | UL94 V-0 or V-1 (optional) | UL 94 |

| مقاومة الأشعة فوق البنفسجية | ممتاز | ASTM G154 |

| مقاوم للانزلاق | R13 or higher (customizable) | EN 124 Anti-slip |

| مقاومة كيميائية | Excellent against H₂S, ammonia, acids | ASTM C581 |

| Lifespan | 30+ years (in outdoor wastewater environments) | Field-tested |

| وزن | 30–70% lighter than cast iron | Based on size/class |

| إعادة التدوير | Yes (Partial) | Thermoset composite |

🧰 5. Performance Benefits

| ميزة | Advantage |

|---|---|

| المقاومة للتآكل | Withstands acidic sewage water, gases, salt, etc. |

| غير موصل | Prevents electrocution; ideal for utility-integrated manholes |

| وزن خفيف | Easy manual handling; reduces back injuries |

| High Load Capacity | Supports vehicles and equipment; conforms to EN 124 |

| No Scrap Value | Theft-proof; no value to metal recyclers |

| سطح مضاد للانزلاق | Improves pedestrian safety; customizable tread designs |

| Customizable Design | Embossed logo, RFID chip, GPS tracker, anti-lift lock |

| Zero Maintenance | No rusting, repainting, or chipping |

| UV & Weather Resistance | Does not crack or fade under sunlight or freeze-thaw cycles |

| Eco-Friendly | Low environmental impact during manufacturing and life cycle |

🌍 6. Application Areas

FRP sewage manhole covers are widely used in:

🏙️ Municipal Infrastructure

-

Urban and rural sewage chambers

-

Manholes in drainage or stormwater systems

-

Septic tank inspection covers

🏭 Industrial Sites

-

Wastewater treatment plants

-

Chemical wastewater drainage

-

Fertilizer, petroleum, and acid plant sewage systems

🏫 Institutional Areas

-

Campus drainage systems

-

Hospitals and facilities with underground sewage

🚦 Transportation

-

Sewage manholes along railways, highways, and tunnels

💡 Utility Corridors

-

Combined electrical + sewage networks with safety demands

🔧 7. Optional Features

| Option | وصف |

|---|---|

| Logo Embossing | City, utility name, or brand |

| Color Customization | Match to zone, hazard level, or theme |

| RFID or GPS Tags | For asset tracking and smart monitoring |

| Locking Systems | Bolted or stainless-steel locking to prevent unauthorized access |

| Hinged Cover Design | Split covers with hydraulic or mechanical hinges for easy access |

| Odor Seals | Rubber gasket options for gas-tight seals |

| Smart Covers | Integration with IoT sensors for monitoring fluid levels or access |

🔬 8. Comparison Table

| ملكية | FRP Sewage Cover | Cast Iron | Concrete |

|---|---|---|---|

| المقاومة للتآكل | ممتاز | فقير | Medium |

| Electrical Insulation | ممتاز | None | Medium |

| وزن | Light (30–60% less) | Heavy | Very Heavy |

| Lifespan | 30+ years | 10–15 years | 5–10 years |

| Theft Risk | None | عالي | None |

| التخصيص | عالي | قليل | قليل |

| Environmental Safety | عالي | Medium | قليل |

| Maintenance Requirements | Minimal | عالي | Medium |

🏗️ 9. Installation Guidelines

-

Ensure base is level – Concrete or brick manhole collar must be flat and cured.

-

Install cover frame – Level frame with proper anchoring (bolts, adhesive).

-

Set the cover – Drop the manhole cover into the frame.

-

Check fit – Ensure no wobble or gaps; adjust frame height as needed.

-

Seal – Use a gasket or rubber lining to block odors if required.

-

Lock – Activate optional locking mechanism if used.

📦 10. Packaging & Logistics

-

Shrink-wrapped or foam-layered protection

-

Individual or palletized delivery

-

Custom crate packaging for export

-

Barcode/RFID labeling for logistics tracking

-

Ocean freight, air freight, or road delivery

📋 11. Certifications & Standards

-

✅ EN 124:2015 – Load class compliance

-

✅ ASTM D790, D570, D2583 – Strength & hardness tests

-

✅ ISO 9001 / ISO 14001 / ISO 45001 – Factory management standards

-

✅ UL94 V-0 – Flame retardant rating (optional)

-

✅ IEC 60093 – Electrical insulation

-

✅ RoHS / REACH – Environmental compliance

-

✅ CE Marking – European regulatory compliance

📈 12. Why Choose FRP for Sewage?

Traditional materials like cast iron are prone to:

-

Rusting in wet environments

-

Cracking or spalling in cold conditions

-

Theft due to high scrap value

-

Weight handling injuries for workers

FRP solves all these issues while being:

-

Maintenance-free

-

Lighter, safer to install

-

قابلة للتخصيص

-

Smart-city ready

🌿 13. Environmental Impact

-

Manufactured with low energy consumption

-

Emits no hazardous fumes

-

Resin formulations are halogen-free and RoHS compliant

-

No leaching into soil or water table

-

100% recyclable through shredding and reuse in filler composites

📊 14. Case Study

Municipality: City of Durban, South Africa

طلب: Sewer cover replacement project

تفاصيل:

-

500+ old cast iron covers replaced

-

Load Class: D400, anti-slip finish, odor-sealing gaskets

-

Time saved in installation: 40%

-

Theft reduced to zero

-

Result: Maintenance savings of $50,000+ annually

💬 15. Frequently Asked Questions (FAQ)

Q: Can FRP sewage covers handle heavy trucks?

A: Yes, we offer D400 to F900 load classes, suitable for highways and industrial zones.

Q: Are they waterproof and odor-resistant?

A: Yes. Optional sealing gaskets block odors and prevent surface water infiltration.

Q: Can I print my utility company name or city logo?

A: Absolutely. We provide customization including embossed text, logos, and RFID tags.

Q: How do they perform in extreme weather?

A: They are UV resistant, freeze-thaw stable, and thermally stable from -40°C to +120°C.

Q: Are they eco-friendly?

A: Yes. Low emissions, recyclable content, and long lifecycle reduce environmental impact.

📞 16. خاتمة

ال FRP Sewage Manhole Cover is a next-generation solution for cities, industries, and infrastructure projects seeking sustainable, secure, and high-performance alternatives to metal or concrete covers. With excellent mechanical strength, corrosion resistance, customizability, and long lifespan, FRP is the ideal choice for future-focused sewage and drainage systems.

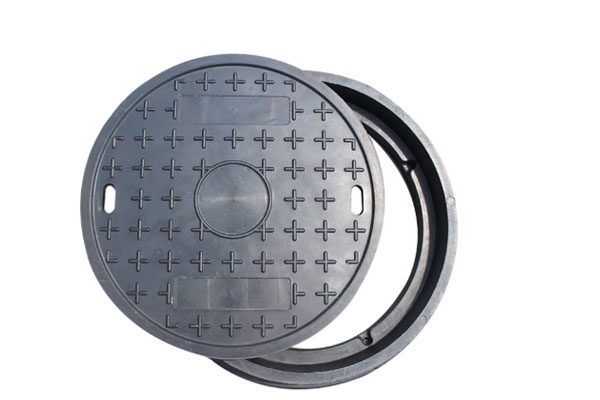

FRP sewage manhole cover

مسلسل :

منتجات البروكسي>طلب

تستخدم على نطاق واسع في الطرق البلدية وهندسة المناظر الطبيعية والحدائق والملاعب الرياضية والملاعب الكبيرة وقطع الأراضي السكنية ، إلخ.

اسم العلامة التجارية :

TF مركب

اسم المنتج :

FRP Electric manhole cover

التعليمات

المنتجات الأخرى ذات الصلة