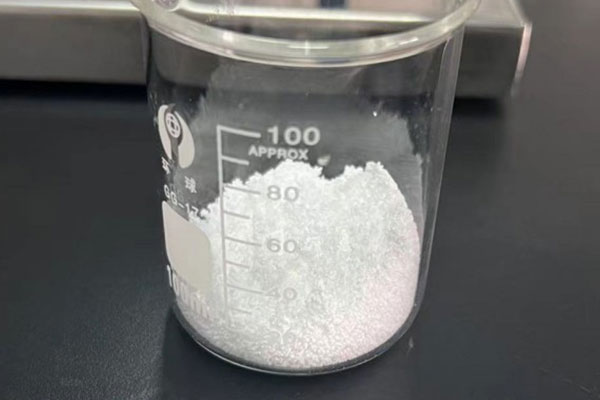

Benzoyl Peroxide (BPO) is a white, crystalline powder known for its strong oxidizing properties. It serves as a free radical initiator in polymerization processes and is utilized across various industries, including plastics, pharmaceuticals, and cosmetics.

مقدمة عن أداء المنتج

2. Chemical Identity

-

Chemical Name: Benzoyl Peroxide

-

CAS Number: 94-36-0

-

Molecular Formula: C₁₄H₁₀O₄

-

Molecular Weight: 242.23 g/mol

-

Synonyms: Dibenzoyl Peroxide, BPO, Benzoic Peroxyanhydride

3. Physical and Chemical Properties

| ملكية | قيمة |

|---|---|

| Appearance | White crystalline powder |

| Odor | Odorless |

| Melting Point | 103–106 °C |

| Boiling Point | Decomposes before boiling |

| كثافة | 1.16 g/cm³ at 25 °C |

| Vapor Pressure | 0.009 Pa at 25 °C |

| Solubility in Water | Insoluble |

| Solubility in Organic Solvents | Soluble in acetone, benzene, chloroform; slightly soluble in ethanol |

| Flash Point | >110 °C |

| Decomposition Temperature | 133 °C (1-minute half-life) |

| Activation Energy | ~125.6 kJ/mol |

| Theoretical Active Oxygen Content | 6.62% |

4. Technical Data Sheet (TDS)

4.1. Product Specifications

| معامل | تخصيص |

|---|---|

| Assay (BPO Content) | 75.00–78.00% |

| Water Content | 21.00–25.00% |

| Free Chloride | ≤0.1% |

| Free Acid (as Benzoic Acid) | ≤0.5% |

| Appearance | White granular powder |

| Bulk Density | 500–600 kg/m³ |

4.2. Thermal Decomposition Data

| Half-Life | Temperature |

|---|---|

| 10 hours | 72–73 °C |

| 1 hour | 92 °C |

| 1 minute | 131 °C |

5. Applications

5.1. Polymer Industry

-

Initiator for Polymerization: BPO is widely used to initiate the polymerization of monomers like styrene, methyl methacrylate, and acrylates in the production of plastics, resins, and adhesives.

5.2. Composite Materials

-

Curing Agent: In unsaturated polyester and vinyl ester resins, BPO acts as a curing agent, facilitating cross-linking during the fabrication of fiberglass-reinforced plastics.

5.3. Pharmaceuticals and Cosmetics

-

Acne Treatment: BPO is a common active ingredient in topical acne medications due to its antibacterial properties.

5.4. Food Industry

-

Bleaching Agent: BPO is employed to bleach flour, whey, and cheese products, improving their appearance.

6. Safety and Handling

6.1. Hazards Identification

-

Oxidizing Agent: BPO is a strong oxidizer and can pose fire and explosion hazards, especially when dry or in contact with combustible materials.

-

Health Hazards: Exposure may cause skin and eye irritation. Inhalation of dust can irritate the respiratory tract.

6.2. Exposure Limits

-

NIOSH Recommended Exposure Limit (REL): TWA 5 mg/m³

-

OSHA Permissible Exposure Limit (PEL): TWA 5 mg/m³

-

Immediately Dangerous to Life or Health (IDLH): 1500 mg/m³

6.3. Personal Protective Equipment (PPE)

-

Eye Protection: Safety goggles or face shield

-

Skin Protection: Protective gloves and clothing

-

Respiratory Protection: Dust mask or respirator in case of inadequate ventilation

6.4. First Aid Measures

-

Inhalation: Move to fresh air. Seek medical attention if symptoms persist.

-

Skin Contact: Wash with soap and water. Remove contaminated clothing.

-

Eye Contact: Rinse cautiously with water for several minutes. Seek medical advice.

-

Ingestion: Do not induce vomiting. Seek immediate medical attention.

7. Storage and Stability

-

شروط التخزين: Store in a cool, dry, well-ventilated area away from heat sources and direct sunlight.

-

Temperature: Maintain storage temperature below 30 °C.

-

التعبئة والتغليف: Typically available in 20 kg or 25 kg containers with inner polyethylene bags and outer fiber drums or cartons.

-

Stability: BPO is stable under recommended storage conditions but decomposes upon heating, shock, or friction.

8. Regulatory Information

-

UN Number: 3104 (for BPO with ≥52% content)

-

Hazard Class: 5.2 (Organic Peroxides)

-

Packing Group: II

-

Regulatory Listings: BPO is listed under various regulatory frameworks, including REACH, TSCA, and OSHA.

9. Environmental Impact

-

Ecotoxicity: BPO is harmful to aquatic life with long-lasting effects.

-

Degradability: It decomposes into benzoic acid and oxygen, which can contribute to environmental oxygen demand.

10. Conclusion

Benzoyl Peroxide powder is a versatile chemical with applications spanning multiple industries. Its efficacy as a polymerization initiator and curing agent makes it invaluable in manufacturing processes. However, due to its reactive nature, strict adherence to safety guidelines is imperative to ensure safe handling and storage.

BPO powder

مسلسل :

Fiberglass Accessories >طلب

Polymer Industry,Composite Materials,Pharmaceuticals and Cosmetics,Food Industry

اسم العلامة التجارية :

TF مركب

اسم المنتج :

BPO powder

التعليمات

س:

What is BPO Paste used for in the fiberglass industry?

أ :

BPO (Benzoyl Peroxide) paste is primarily used as a curing initiator for unsaturated polyester and vinyl ester resins. It helps start the polymerization process in various fiberglass manufacturing methods like hand lay-up, spray-up, pultrusion, casting, and filament winding.

س:

Why is BPO used in paste form rather than powder?

أ :

Safer (less risk of explosion or fire) Easier to handle and mix Less dusty More stable during storage and transportation

س:

Can BPO paste be used alone for curing?

أ :

No. BPO paste requires a promoter/accelerator—most commonly cobalt octoate—to decompose properly and generate free radicals for curing.

س:

What is the typical dosage of BPO paste in fiberglass production?

أ :

The standard dosage is usually 1.0% – 2.5% by resin weight, depending on resin type, curing speed required, and temperature.

المنتجات الأخرى ذات الصلة