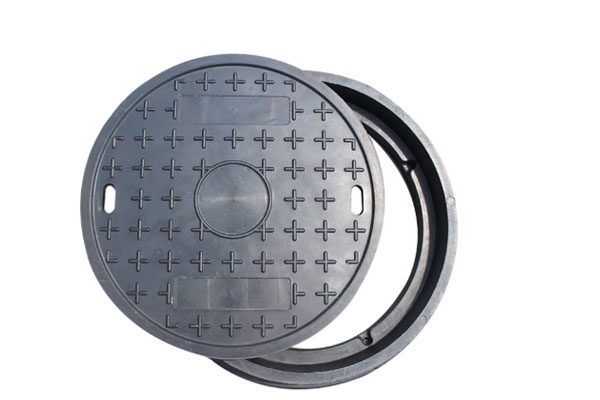

FRP Electric Manhole Covers, also known as Glass Fiber Reinforced Plastic Electrical Access Covers, are composite covers specifically engineered for underground cable chambers, telecom vaults, power distribution pits, and other electrical utility applications. Made from high-strength fiberglass and thermosetting resin, these manhole covers offer exceptional resistance to corrosion, non-conductivity, anti-slip properties, and durability in even the harshest environmental conditions.

مقدمة عن أداء المنتج

Unlike traditional metal manhole covers, FRP electric manhole covers are non-metallic, non-sparking, electrically non-conductive، و corrosion-free, making them ideal for use in power grids, telecom networks, and underground electrical infrastructure.

🧱 2. Construction & Materials

The primary components of an FRP electric manhole cover include:

-

Fiberglass Reinforcement (Glass Fiber Roving, Chopped Strands, Mat)

-

Thermosetting Resin System (Unsaturated Polyester, Vinyl Ester, or Epoxy)

-

Fillers (Quartz Powder, Calcium Carbonate, Flame Retardants)

-

Surface Gelcoat (Anti-UV, Anti-Aging, Color Customizable)

The cover is manufactured via صب الضغط under high temperature and pressure, resulting in a solid, high-strength, and homogeneous product.

🧪 3. TDS (Technical Data Sheet)

| معامل | Specification / Value | Standard / Notes |

|---|---|---|

| Product Type | FRP Electric Manhole Cover | Round / Square / Custom |

| Available Sizes | 300 mm to 1200 mm diameter | Custom dimensions available |

| Load Class | A15, B125, C250, D400, E600, F900 | EN124 Standard |

| سعة التحميل | 1.5T – 90T | Based on usage (pedestrian to heavy duty) |

| وزن | 5 – 80 kg (depending on size and load class) | 40–70% lighter than metal |

| مقاومة التأثير | ≥ 25 J | ISO 179 |

| قوة الانحناء | ≥ 150 MPa | ASTM D790 |

| قوة الضغط | ≥ 300 MPa | ISO 604 |

| Water Absorption | < 0.1% | ASTM D570 |

| Thermal Conductivity | 0.25 W/m·K | ASTM C177 |

| Electrical Insulation | > 10⁶ MΩ | IEC 60093 |

| مقاومة الحريق | V-0 or V-1 (depending on resin) | UL94 / ASTM E84 |

| مقاومة الأشعة فوق البنفسجية | Excellent (Gelcoated surface) | ASTM G154 |

| سطح مضاد للانزلاق | Yes (Sandblasted / Tread Pattern) | EN124 Anti-Slip Surface |

| Lifespan | >30 years | Maintenance-free |

| المقاومة للتآكل | Excellent (Resin-based) | ASTM C581 |

| التخصيص | Logo, color, load class, RFID, lockable, hinge | Optional features |

⚙️ 4. Manufacturing Process

The FRP electric manhole cover is manufactured through the high-pressure compression molding process:

-

Mold Preparation – Precision steel molds are cleaned and pre-treated.

-

Resin and Fiber Mixing – Thermoset resin is mixed with reinforcements and fillers.

-

صب – The material is placed into a heated mold and compressed at high pressure.

-

علاج – Heat accelerates polymerization, hardening the composite.

-

Demolding & Finishing – The cured cover is ejected, then trimmed, sanded, and coated.

-

المعالجة السطحية – Anti-slip texture and UV-resistant topcoat are applied.

-

الاختبار – Each cover undergoes physical and quality inspections.

🔋 5. Application Areas

FRP Electric Manhole Covers are extensively used in:

🏙️ Urban Infrastructure

-

Streetlight power access

-

Underground electricity lines

-

Municipal electrical pits

📡 Telecom Networks

-

Fiber optic cable chambers

-

Telecom data centers

-

5G base stations

🏭 Industrial Facilities

-

Power plant cable trench access

-

High-voltage cable management

-

Remote control panel chambers

🚦 Transport & Smart Roads

-

Smart highway cable pits

-

Railway signaling boxes

-

Airport electrical vaults

🏗️ Construction Sites

-

Temporary electrical service pits

-

Switchgear access

-

Substation electrical enclosures

🧯 Fire-Sensitive Zones

-

Petrochemical zones

-

Gas pipeline chambers

-

Refineries and flammable storage

🌟 6. Key Features & Benefits

| ميزة | Benefit |

|---|---|

| غير موصل | Prevents electric shock in public environments |

| مقاومة للتآكل | Suitable for wet, coastal, or chemical-prone areas |

| وزن خفيف | Easy manual handling; no lifting equipment required |

| High Load Capacity | Supports traffic, trucks, or heavy machinery |

| Anti-Theft | No metal scrap value; optional locking mechanism |

| Anti-Slip Texture | Ensures pedestrian safety in rain or snow |

| Customizable Appearance | Can embed logo, text, or RFID for asset management |

| Weather & UV Resistant | Long-term exposure without cracking or color loss |

| خيارات مقاومة الحرائق | Safe in fire-sensitive electrical areas |

| Zero Maintenance | No repainting, rust removal, or corrosion protection |

🔌 7. Advantages vs Traditional Covers

| معامل | FRP Electric Cover | Cast Iron / Concrete |

|---|---|---|

| وزن | Light (5–30 kg) | Heavy (30–100+ kg) |

| Conductivity | Non-conductive | Conductive (unsafe) |

| المقاومة للتآكل | ممتاز | Rust-prone / spalling |

| Lifespan | 30+ years | 5–15 years |

| Theft Risk | No scrap value | High theft risk |

| Maintenance | None | Requires painting, sealing |

| التخصيص | High (Color, logo, RFID) | Limited |

📐 8. Design Types & Options

FRP Electric Manhole Covers can be supplied in:

🔹 Shapes

-

Round

-

مربع

-

Rectangular

-

Hinged or Split cover

🔹 Load Ratings (per EN124)

-

A15 – Pedestrian (1.5 tons)

-

B125 – Sidewalks, light vehicles

-

C250 – Urban roads

-

D400 – Heavy traffic areas

-

E600/F900 – Airports, ports, loading bays

🔹 Surface Patterns

-

Diamond tread

-

Anti-slip grainy

-

Brushed finish

🔹 Custom Features

-

RFID smart tag embedment

-

Stainless steel locking mechanisms

-

Hinges with hydraulic assist

-

Frame with gasket for sealing

🧰 9. Installation Instructions

-

Prepare foundation with concrete frame or pre-set ring.

-

Place cover frame using level alignment.

-

Allow concrete to cure if freshly poured.

-

Install cover into the frame.

-

Test alignment for flush finish and proper load distribution.

-

Lock (if applicable) using the provided mechanism.

Always ensure compatibility of size, load class, and sealing requirements before installation.

📋 10. Testing & Quality Control

Each manhole cover undergoes multiple quality checks:

| Test Type | Standard / Procedure |

|---|---|

| اختبار التحميل | EN124 or AASHTO H20 |

| Impact Test | ISO 179 |

| Water Absorption | ASTM D570 |

| Electrical Resistance | IEC 60093 |

| UV Exposure | ASTM G154 |

| Surface Hardness | Barcol Hardness ASTM D2583 |

| Dimensional Tolerance | ISO 286 |

📦 11. Packaging & Delivery

-

Individual covers shrink-wrapped or foam-packed

-

Palletized for bulk shipments

-

Barcode/RFID sticker for tracking

-

Custom crates for overseas delivery

📈 12. Market Trends & Use Cases

With increasing demand for smart infrastructure and sustainable materials, FRP electric manhole covers are rapidly replacing cast iron and concrete variants worldwide. Cities aiming for safer pedestrian zones, utility providers modernizing cable networks, and private developers pursuing low-maintenance solutions are all turning to composite access covers.

📊 Use Case Example: Smart City Cable Access

In an urban fiber-optic installation project:

-

300+ FRP manhole covers replaced old rusting units.

-

Load class: B125 with embedded RFID.

-

Project life extended by 30 years with minimal upkeep.

-

Reduced labor cost due to lightweight design.

✅ 13. Standards Compliance & Certification

-

EN124:1994 / EN124-1:2015 (Europe)

-

ASTM D790 / D570 / D2583 / D2996

-

ISO 179 / ISO 604

-

UL 94 (Flame Retardancy)

-

IEC 60093 (Electrical Insulation)

-

RoHS / REACH / CE Certified

-

ISO 9001 / ISO 14001 / ISO 45001

🌿 14. Environmental Impact

-

100% non-toxic and non-leaching

-

Recyclable after life cycle (thermoset + glass)

-

No heavy metal or solvent emissions

-

Compatible with green building certifications (LEED/BREEAM)

📞 15. Customization Services

We offer full OEM/ODM capabilities:

-

Size, shape, color

-

Logo and city branding

-

RFID + QR Code integration

-

Lock and hinge systems

-

Multi-layer anti-slip textures

-

Special flame retardant or anti-static resin systems

🧾 خاتمة

ال FRP Electric Manhole Cover represents a new generation of intelligent, safe, and maintenance-free access solutions for modern cities and infrastructure. With unmatched mechanical properties, electrical insulation, light weight, and corrosion resistance, FRP covers are redefining the safety and longevity of underground access systems in the electrical and telecom industries.

FRP Electric manhole cover

مسلسل :

منتجات البروكسي>طلب

تستخدم على نطاق واسع في الطرق البلدية وهندسة المناظر الطبيعية والحدائق والملاعب الرياضية والملاعب الكبيرة وقطع الأراضي السكنية ، إلخ.

اسم العلامة التجارية :

TF مركب

اسم المنتج :

FRP Electric manhole cover

التعليمات

المنتجات الأخرى ذات الصلة