A GRP (Glass Reinforced Plastic) I Beam, also known as an FRP (Fiberglass Reinforced Plastic) I Beam, is a structural profile designed for high-strength, lightweight, and corrosion-resistant applications. It is manufactured using the pultrusion process, ensuring superior mechanical properties compared to conventional materials like steel, aluminum, or wood.

مقدمة عن أداء المنتج

A GRP (Glass Reinforced Plastic) I Beam, also known as an FRP (Fiberglass Reinforced Plastic) I Beam, is a structural profile designed for high-strength, lightweight, and corrosion-resistant applications. It is manufactured using the pultrusion process, ensuring superior mechanical properties compared to conventional materials like steel, aluminum, or wood.

📌 دلائل الميزات:

✅ Corrosion-resistant (ideal for harsh environments)

✅ وزن خفيف (easy to install & transport)

✅ نسبة القوة إلى الوزن عالية

✅ Non-conductive (electrically insulating)

✅ صيانة منخفضة (long service life)

2. Conventional Specifications & Dimensions

GRP I Beams are available in various sizes and thicknesses, typically in metric and imperial units.

Common Sizes of GRP I Beams

| Size (mm) | Flange Width (mm) | Web Thickness (mm) | Size (inches) | Flange Width (inches) | Web Thickness (inches) |

|---|---|---|---|---|---|

| 100 x 50 x 6 | 50 | 6 | 4" x 2" x 0.24" | 2" | 0.24" |

| 150 x 75 x 6 | 75 | 6 | 6" x 3" x 0.24" | 3" | 0.24" |

| 200 x 100 x 8 | 100 | 8 | 8" x 4" x 0.31" | 4" | 0.31" |

| 250 x 125 x 10 | 125 | 10 | 10" x 5" x 0.39" | 5" | 0.39" |

| 300 x 150 x 12 | 150 | 12 | 12" x 6" x 0.47" | 6" | 0.47" |

📌 Standard Lengths: 3m, 6m, 12m (custom lengths available).

3. Key Advantages of GRP I Beams

✅ المقاومة للتآكل – Ideal for marine, chemical, and industrial applications.

✅ Lightweight but Strong – 75% lighter than steel while maintaining high strength.

✅ غير موصل – Ensures electrical insulation, making it safe for electrical installations.

✅ Weather Resistant – UV-stable, unaffected by extreme temperatures.

✅ Easy to Install & Handle – Requires no heavy lifting equipment.

✅ صيانة منخفضة – No rusting, repainting, or chemical treatments required.

✅ خيارات مقاومة الحرائق – Available in fire-resistant resin formulations.

4. Comparison: GRP I Beam vs. Steel I Beam vs. Aluminum I Beam

| ملكية | GRP I Beam | Steel I Beam | Aluminum I Beam |

|---|---|---|---|

| المقاومة للتآكل | ✅ Excellent | ❌ Prone to rust | ⚠️ Moderate |

| وزن | ✅ Lightweight | ❌ Heavy | ✅ Lighter than steel |

| Strength-to-Weight Ratio | ✅ High | ✅ High | ✅ High |

| Electrical Insulation | ✅ Non-conductive | ❌ Conductive | ❌ Conductive |

| Thermal Conductivity | ✅ Low | ❌ High | ⚠️ Medium |

| Maintenance | ✅ Minimal | ❌ Requires coatings | ✅ Minimal |

| Lifespan | ✅ 20+ years | ❌ Prone to corrosion | ✅ 10-15 years |

5. Types of GRP I Beams Based on Resin Composition

📌 Polyester Resin – General-purpose, cost-effective.

📌 راتنج فينيل استر – Superior chemical and corrosion resistance.

📌 راتينج الفينولي – High fire resistance, low smoke emission.

📌 راتنجات الايبوكسي – High mechanical strength and impact resistance.

6. Applications of GRP I Beams

🌉 Construction & Infrastructure – Bridges, walkways, platforms, and support structures.

⚡ Electrical & Power Industry – Structural framing for electrical enclosures.

🏗 Industrial Plants – Chemical-resistant frameworks for factories.

🌊 Marine & Offshore – Used in shipbuilding, offshore oil rigs, and seawater-exposed structures.

🏭 المصانع الكيميائية – Structural supports in corrosive environments.

🚇 Rail & Transport – Lightweight framing and structural reinforcements.

7. GRP I Beam Installation & Processing

🛠 Cutting: Can be cut with carbide or diamond-tipped saws.

🔩 Fastening: Drilled with standard HSS drill bits, can use stainless steel bolts.

🛠 الترابط: Can be bonded using structural adhesives for extra strength.

📌 Tip: Use dust masks and proper ventilation when cutting or drilling GRP to avoid inhaling fiberglass particles.

8. Fire Resistance of GRP I Beams

🔥 Standard GRP – Moderate fire resistance.

🔥 Fire-Retardant GRP (FR-rated) – Complies with BS 476, ASTM E84, and EN 13501 standards.

📌 Ensure you choose the right resin type based on your fire safety requirements.

9. Lifespan & Durability of GRP I Beams

⏳ 20+ years lifespan in most environments due to corrosion resistance, UV stability, and high mechanical strength.

10. Maintenance & Care of GRP I Beams

🧼 تنظيف: Wash with mild detergent and water.

🔍 تقتيش: Check for any surface damage, especially in high-load areas.

🌞 حماية من الأشعة فوق البنفسجية: Some GRP beams come with UV-resistant coatings for prolonged outdoor exposure.

11. Are GRP I Beams More Expensive Than Steel?

💰 Initial cost: Slightly higher than steel.

💰 Long-term cost: Lower due to reduced maintenance, installation costs, and longer lifespan.

12. Customization Options for GRP I Beams

🛠 Available Customizations:

📌 Size & Thickness

📌 Resin Type (Fire-resistant, Chemical-resistant, etc.)

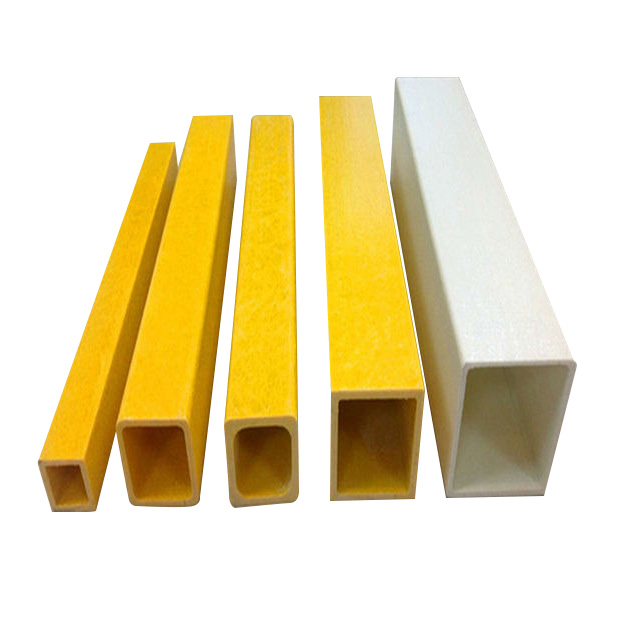

📌 Color (Gray, Green, Yellow, Red, Black, etc.)

📌 Length (3m, 6m, 12m, or custom cut-to-size)

13. International Standards & Certifications for GRP I Beams

GRP I Beams meet industry standards, including:

✅ ISO 9001 (Quality Management)

✅ EN 13706 (Structural GRP Profiles)

✅ ASTM D4385 (Pultruded GRP Standards)

✅ BS 476 (Fire Resistance Tests)

💡 Need a quotation or technical consultation? Let me know your project details! 🚀

GRP I Beam

مسلسل :

المنتجات الرئيسية>طلب

🌉 Construction & Infrastructure – Bridges, walkways, platforms, and support structures. ⚡ Electrical & Power Industry – Structural framing for electrical enclosures. 🏗 Industrial Plants – Chemical-resistant frameworks for factories. 🌊 Marine & Offshore – Used in shipbuilding, offshore oil rigs, and seawater-exposed structures. 🏭 Chemical Plants – Structural supports in corrosive environments. 🚇 Rail & Transport – Lightweight framing and structural reinforcements.

اسم العلامة التجارية :

TF مركب

اسم المنتج :

GRP I Beam

مادة :

الألياف الزجاجية

لون :

Yellow,Gray,Other

التعليمات

س:

How strong is a GRP I Beam compared to steel?

أ :

GRP I Beams have a high strength-to-weight ratio, meaning they provide comparable strength to steel but are up to 75% lighter. While they may not match steel in absolute strength, they are strong enough for most structural applications where corrosion resistance and lightweight materials are needed.

س:

What are the standard sizes of GRP I Beams?

أ :

GRP I Beams come in various sizes, with common dimensions including: 100 x 50 x 6 mm (4" x 2" x 0.24") 150 x 75 x 6 mm (6" x 3" x 0.24") 200 x 100 x 8 mm (8" x 4" x 0.31") 250 x 125 x 10 mm (10" x 5" x 0.39") 300 x 150 x 12 mm (12" x 6" x 0.47") 📌 Custom sizes available upon request. 4. What are the key advantages of GRP I Beams? ✅ Corrosion Resistance – Ideal for marine, chemical, and outdoor environments. ✅ Lightweight – Easier to transport and install compared to steel. ✅ Non-Conductive – Electrically and thermally insulating, safe for power plants. ✅ Low Maintenance – No rust, repainting, or chemical treatments required. ✅ Fire Retardant Options – Available in fire-resistant formulations. 5. Are GRP I Beams fire-resistant? Yes, fire-retardant GRP I Beams are available. These comply with BS 476, ASTM E84, and EN 13501 fire safety standards. However, standard GRP is not naturally fireproof. 6. How are GRP I Beams manufactured? GRP I Beams are produced through pultrusion, where continuous fiberglass strands are pulled through a resin bath and shaped into an I-profile before being cured and hardened. 7. How long do GRP I Beams last? GRP I Beams have a lifespan of 20+ years, even in harsh conditions, due to their corrosion resistance and UV stability. 8. Can GRP I Beams be cut and drilled? Yes, GRP I Beams can be cut using carbide or diamond-tipped saws and drilled with HSS (High-Speed Steel) drill bits. Proper dust protection and ventilation are recommended during processing. 9. How do GRP I Beams compare to steel and aluminum? Property GRP I Beam Steel I Beam Aluminum I Beam Corrosion Resistance ✅ Excellent ❌ Prone to rust ⚠️ Moderate Weight ✅ Lightweight ❌ Heavy ✅ Lighter than steel Strength-to-Weight Ratio ✅ High ✅ High ✅ High Electrical Insulation ✅ Non-conductive ❌ Conductive ❌ Conductive Maintenance ✅ Minimal ❌ Requires coatings ✅ Minimal 10. What are the main applications of GRP I Beams? 🔹 Construction & Infrastructure – Bridges, platforms, walkways. 🔹 Industrial Plants – Chemical-resistant support structures. 🔹 Marine & Offshore – Shipbuilding, offshore platforms. 🔹 Electrical Installations – Safe, non-conductive framework. 🔹 Transport & Rail – Lightweight structural reinforcements. 11. What colors are available for GRP I Beams? GRP I Beams are available in gray, green, yellow, red, black, and custom colors upon request. 12. Are GRP I Beams UV-resistant? Yes, most GRP I Beams have built-in UV stabilization, preventing degradation from sun exposure. 13. Can GRP I Beams be used in load-bearing structures? Yes, GRP I Beams are used in load-bearing applications, but proper design calculations must be done to ensure structural integrity. 14. How do I install GRP I Beams? Installation is simple using: 🔩 Bolting – Pre-drilled holes with stainless steel bolts. 🛠 Bonding – Structural adhesives for added strength. 🔧 Mechanical Fasteners – Brackets and clamps for extra support. 15. What is the cost of a GRP I Beam compared to steel? 💰 Initial cost: Slightly higher than steel. 💰 Total lifecycle cost: Lower due to reduced maintenance and long service life. 16. Where can I buy GRP I Beams? GRP I Beams can be purchased from: 🏭 Industrial suppliers 🏗 Construction material distributors 🌍 FRP/GRP manufacturers 💡 Still have questions? Let me know your specific requirements! 🚀

س:

What are the key advantages of GRP I Beams?

أ :

✅ Corrosion Resistance – Ideal for marine, chemical, and outdoor environments. ✅ Lightweight – Easier to transport and install compared to steel. ✅ Non-Conductive – Electrically and thermally insulating, safe for power plants. ✅ Low Maintenance – No rust, repainting, or chemical treatments required. ✅ Fire Retardant Options – Available in fire-resistant formulations.

س:

Are GRP I Beams fire-resistant?

أ :

Yes, fire-retardant GRP I Beams are available. These comply with BS 476, ASTM E84, and EN 13501 fire safety standards. However, standard GRP is not naturally fireproof.

س:

How are GRP I Beams manufactured?

أ :

GRP I Beams are produced through pultrusion, where continuous fiberglass strands are pulled through a resin bath and shaped into an I-profile before being cured and hardened.

س:

How long do GRP I Beams last?

أ :

GRP I Beams have a lifespan of 20+ years, even in harsh conditions, due to their corrosion resistance and UV stability.

المنتجات الأخرى ذات الصلة