162E Assembled Roving is produced by using E6 glass formulation and coated with a silane-based sizing. It is specially designed for the reinforcement of epoxy resin, and suitable for the chopping process.

162E is suitable for use as chopped roving for pipes, wind fabrics, and chopped strand mats, offering excellent mechanical properties to the composites it reinforces.

Product performance introduction

Assembled Roving for Chopping For Pipes 162E

Assembled Roving for Chopping for Pipes 162E is a specific type of fiberglass reinforcement material used in the manufacturing of composite pipes. Here are the key features and details associated with it:

Product Overview

- Type: Assembled Roving

- Product Code: 162E

- Material: E-Glass Fibers

- Usage: Designed for chopping and further processing into fiberglass-reinforced pipes.

Characteristics

-

High Strength and Stiffness:

- Provides excellent mechanical properties suitable for demanding applications, ensuring durability and resistance to deformation.

-

Chemical Resistance:

- Superior resistance to a wide range of chemicals, making it ideal for use in environments where corrosive substances are present.

-

Thermal Stability:

- Capable of withstanding elevated temperatures without significant degradation, allowing for reliable performance in high-temperature applications.

-

Versatile Processing:

- Designed for easy chopping to various lengths, which facilitates integration into different manufacturing processes such as filament winding or pultrusion.

Applications

- Pipe Manufacturing:

- Commonly used in the production of fiberglass-reinforced pipes for various industries, including:

- Chemical processing and transport.

- Marine applications, including piping for boats and offshore structures.

- Wastewater treatment systems.

- Oil and gas industries for transporting hydrocarbons.

Benefits

-

Lightweight:

- Offers weight savings compared to traditional metal pipes, which can reduce shipping and installation costs.

-

Cost-Effective:

- Provides a combination of performance and cost efficiency for manufacturers.

-

Strength-to-Weight Ratio:

- High strength-to-weight ratio contributes to enhanced performance in a variety of applications.

Processing Techniques

- Chopping:

- Can be chopped into specific lengths for various fabrication processes.

- Filament Winding:

- Used to create strong, pressure-rated pipes by winding the rovings around a mandrel.

- Pultrusion:

- Continuous production of composite sections with consistent dimensions and properties.

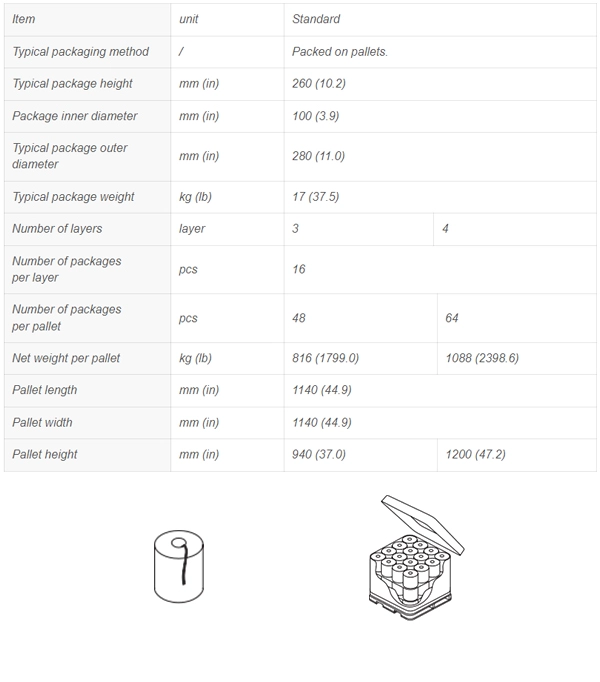

Packaging

- Typically packaged on bobbins for ease of handling and integration into manufacturing processes.

Conclusion

Assembled Roving for Chopping for Pipes 162E is a vital material in the composite manufacturing industry, particularly for applications requiring high strength, chemical resistance, and thermal stability. Its versatility in processing ensures that it can be adapted for a range of production techniques, making it a popular choice for engineers and manufacturers.

Product Features

- Good bonding with epoxy resin

- Low fuzz and good choppability and dispersion

- Excellent acid corrosion resistance

- Excellent mechanical properties

- Good anti-static property

Specification

| Glasstype | E6 | |

| Sizingtype | Silane | |

| Typicalfilamentdiameter(μm) | 13 | |

| Typicallineardensity(tex) | 2400 | 4800 |

| Example |

E6R13-2400-162E |

|

Technical Parameters

|

Item |

Linear density variation |

Moisture content |

Sizing content |

Stiffness |

|

Unit |

% |

% |

% |

mm |

|

Test menthod |

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3375 |

|

Standard range |

± 4 |

≤ 0.07 |

0.90 ± 0.15 |

120 ± 20 |

Instructions

- The product is best used within 12 months after production, and should be kept in the original package before use.

- Care should be taken when using the product to prevent it from being scratched or damaged.

- The temperature and humidity of the product should be conditioned to be close or equal to the ambient temperature and humidity before use, and the ambient temperature and humidity should be properly controlled during the use.

- The cutter rollers and rubber rollers should be maintained regularly.

Packaging

Storage

Unless otherwise specified, the fiberglass products should be stored in a dry,cool and moisture-proof area.The best temperature and humidity should be maintained at -10℃~35℃ and ≤80% respectively. To ensure safety and avoid damage to the product, the pallets should be stacked not more than three layers high. When the pallets are stacked in two or three layers, special care should be taken to correctly and smoothly move the upper pallet.

More products in the same series

Assembled Roving for Chopping For Pipes 162E

Series :

Fiberglass Assemble Roving >application

Chemistry and Chemical / Infrastructure / Marine / Petrochemical / Building and Construction

Glass type :

E6

Sizing type :

Silane

Typical filament diameter (μm) :

13

Typical linear density (tex) :

2400 | 4800

Example :

E6R13-2400-162E

FAQ

Q :

Are you a factory? Where are you located?

A :

We are manufacturer of FRP grating and pultruded profiles, trader of FRP yarn materials. We are the largest distributor of China Jushi Co. We also sell products of several FRP yarn manufacturers. We are in Anhui, China.

Q :

What information is recommended for the inquiry?

A :

1. Which tex you need? 2. What the application you use it for? Or the tecnologh, is weaving, pultrusion or winding? 3. How many quantity do you need? 4. What resin do you combined for? Polyester resin or epoxy resin? 5. Do you need FOB or CIF price, if CIF, please tell us your port.

Q :

What's the MOQ?

A :

Usually 1 Ton

Q :

Package & Shipping

A :

Normal package:carton(Incuded in the unite price) Special Packge: need to charge according the actual situation. Normal shipping :your nominated Freight forwarding.

Q :

When can I offer?

A :

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price pls call us or tell us in your email , so that we can reply you priority.

Q :

How do you charge the sample fees?

A :

If you need a samples from our stock, we can provide to you for free, but you need to pay the freight charge.If you need a special size, We will charge the sample making fee which is refundable when you place an order.

Q :

What's your delivery time for production?

A :

If we have stock , can delivery in 7 days ; if without the stock, need 7~15 days !

Other related products