Bulk Molding Compounds (BMC) and Sheet Molding Compounds (SMC) are both fiber reinforced materials, typically utilize glass strand fibers of varying lengths.

Product performance introduction

BMC stands for Bulk Molding Compound, which is a type of thermosetting composite material used in various manufacturing processes.

BMC Resin refers to the thermoset resin that is a key component of the BMC material. The main characteristics of BMC Resin include:

-

Thermoset Resin:

- The resin is a thermosetting polymer, typically unsaturated polyester or vinyl ester.

- These resins undergo irreversible crosslinking during the molding process.

-

Filled Resin:

- The resin is filled with various reinforcing fillers, such as chopped glass fibers, mineral fillers (e.g., calcium carbonate, talc), and other additives.

- The fillers improve the mechanical, thermal, and dimensional properties of the final composite.

-

Thickened Resin:

- The resin is thickened to a dough-like consistency, making it suitable for compression or injection molding.

- Thickening agents, such as magnesium oxide or organic peroxides, are added to the resin to control the viscosity and handling characteristics.

-

Molding Characteristics:

- BMC Resin can be easily handled, metered, and molded using compression or injection molding techniques.

- The thickened resin allows for complex part geometries and close dimensional tolerances.

-

Applications:

- BMC Resins are commonly used in the production of a wide range of molded composite parts, including:

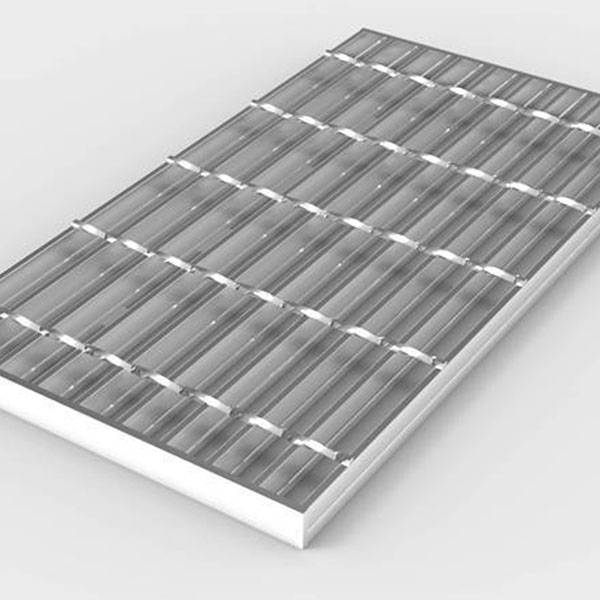

- Automotive components (e.g., engine covers, brackets, housings)

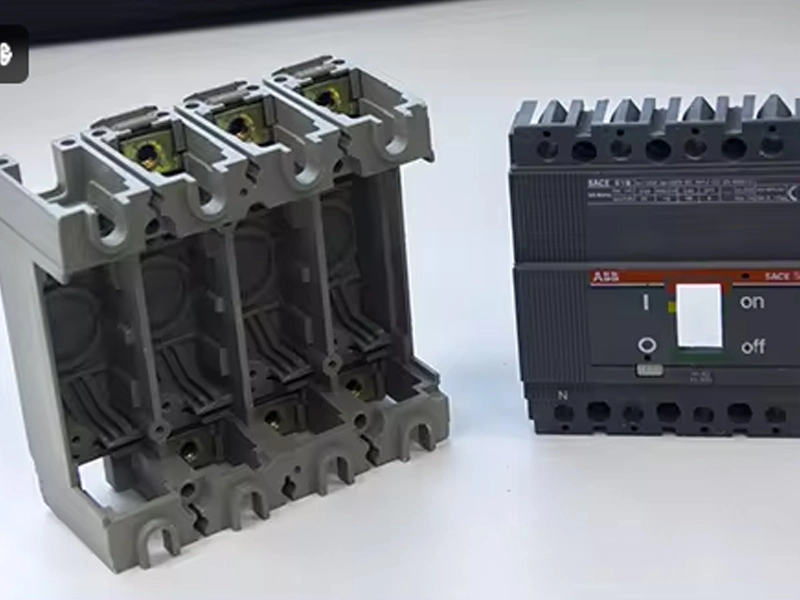

- Electrical and electronic components (e.g., circuit breakers, switch housings)

- Household appliances (e.g., washing machine tubs, dishwasher racks)

- Industrial equipment (e.g., pump housings, gears, pulleys)

- BMC Resins are commonly used in the production of a wide range of molded composite parts, including:

The specific formulation of the BMC Resin is tailored to meet the performance requirements of the target application, such as mechanical strength, thermal resistance, electrical properties, and surface finish. The selection of the appropriate BMC Resin is crucial for ensuring the desired properties and manufacturability of the final composite part.

BMC Resin

Series :

Unsaturated Polyester Resin >application

Automotive,Electrical and Electronics,Industrial Equipment,Building and Construction,Household Appliances..

Brand name :

BMC Resin

FAQ

Other related products