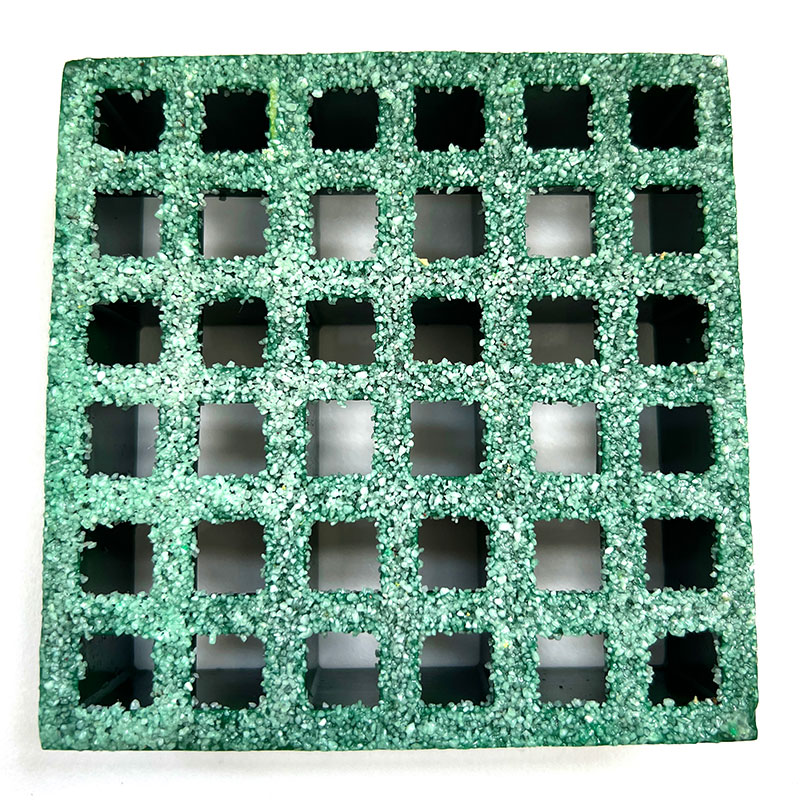

Fiberglass reinforced plastic grating (also known as FRP grating, glass reinforced plastic grating or fiberglass grating) is a composite material manufactured by combining a matrix of resin and fiberglass. FRP grating is a structural product that can be weight-bearing between spans.

Product performance introduction

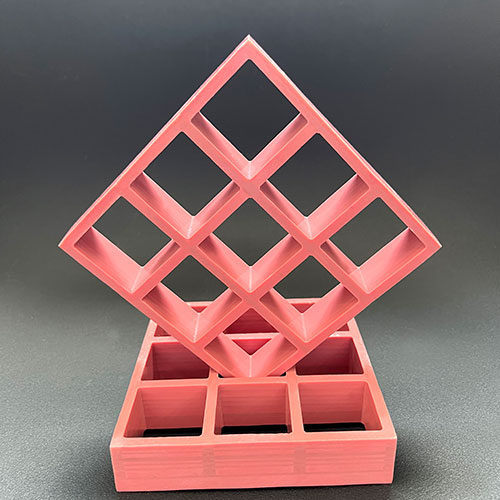

We bring you samples of our latest research and development and hope that new and old customers will discuss and co-operate with us.

CAMX Composite refers to the advanced materials and composite technologies showcased at the CAMX (The Composites and Advanced Materials Expo). This expo highlights innovations in composite materials, which are engineered materials made from two or more constituent materials with significantly different physical or chemical properties. Here’s a deeper look into CAMX Composite:

Key Aspects of CAMX Composite:

-

Material Types:

- Fiber-Reinforced Composites: These include materials like carbon fiber, glass fiber, and aramid fiber, which provide strength and stiffness.

- Matrix Materials: Common matrix materials include thermosetting resins (like epoxy) and thermoplastics, which bind the fibers together.

-

Applications:

- Aerospace: Lightweight and high-strength composites are crucial for aircraft structures and components.

- Automotive: Composites are used to reduce vehicle weight, improve fuel efficiency, and enhance performance.

- Marine: Used in boat hulls and components for their resistance to corrosion and lightweight properties.

- Construction: Composites are utilized in building materials, bridges, and infrastructure for their durability and strength.

-

Manufacturing Techniques:

- Layup Processes: Hand layup, automated tape laying, and filament winding are common methods for creating composite structures.

- Injection Molding: Used for thermoplastic composites, allowing for complex shapes and high production rates.

- 3D Printing: Emerging technology in composite manufacturing, enabling rapid prototyping and custom parts.

-

Sustainability:

- The composites industry is increasingly focusing on sustainable practices, including the development of bio-based resins and recycling methods for composite materials.

-

Innovation and Research:

- CAMX serves as a platform for researchers and companies to present their latest findings and innovations in composite technology, fostering collaboration and advancement in the field.

Benefits of CAMX Composite:

- Access to Cutting-Edge Technology: Attendees can explore the latest advancements in composite materials and manufacturing processes.

- Networking Opportunities: Connect with industry leaders, researchers, and potential partners to discuss collaborations and innovations.

- Educational Resources: Gain insights from workshops and presentations on best practices, market trends, and future directions in the composites industry.

CAMX Samples FRP Molded Grating

Series :

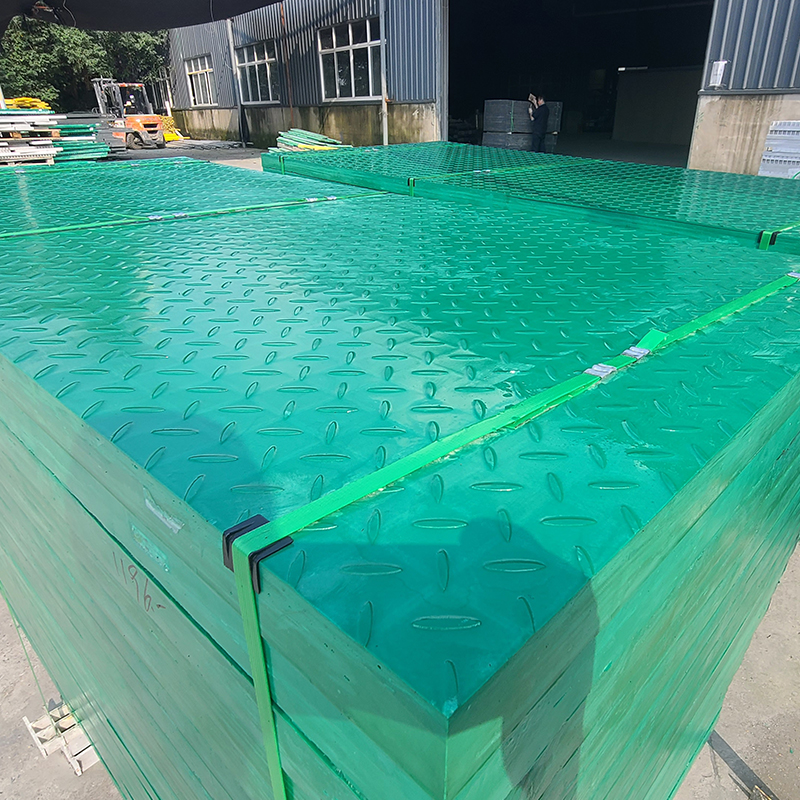

Main Products >application

Chemical industry, paper industry, power plant, sewage treatment plant, offshore drilling platform, food processing plants melting.Refineries, mines, salt farms, nuclear power plants.battery plants and so on. Can be used as: pedestrian walkway, bridge plank, work lndustrial floor, operating platform, trench cover, pallet, guardrail, fence, shelf, isolation belt, green walkway, Floor step,etc.

Brand name :

TFcomposite

Product name :

FRP Molded Grating

Technique :

Molded

Material :

Unsaturated polyester resin and glass fiber roving

MOQ :

50pcs

FAQ

Q :

Are you a factory that produces FRP molded grating?

A :

Yes, we are a professional manufacturer of FRP gratings, we have covers an area of nearly 15,000 square meters, has nearly 120 employees, equipped more than 100 sets of standard grating molds, 15 automatic pultrusion lines.

Q :

How to choose if there is a requirement for the load bearing of the FRP grating?

A :

It depends on the application where you buy the grating, whether it is a walkway or a passing vehicle.

Q :

We are a decoration company, can we buy your FRP grating as decorations?

A :

Yes, our colors can be customized according to customer needs, we can make all the colors on the Raul color card.

Q :

Do you guarantee after-sales service when purchasing your FRP grating?

A :

Yes, we can guarantee two years of after-sales.

Other related products