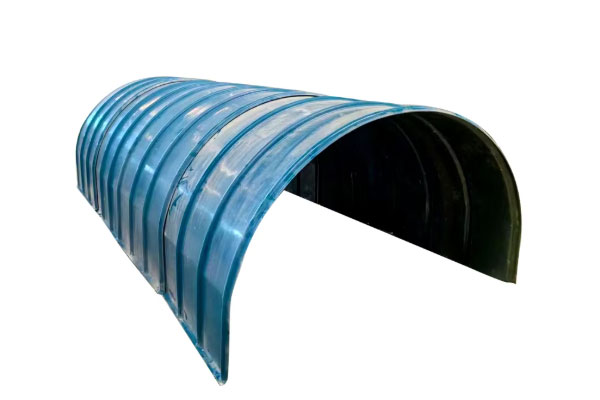

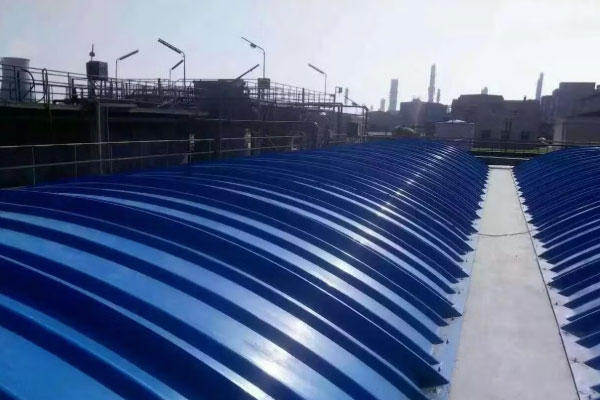

Fiberglass Reinforced Plastic (FRP) Arch Covers are engineered structures designed to provide protection and containment in various industrial and environmental applications. Their arch-shaped design offers structural strength, while the FRP material ensures durability and resistance to corrosive environments.

Einführung zur Produktleistung

Fiberglass Reinforced Plastic (FRP) Arch Covers are engineered structures designed to provide protection and containment in various industrial and environmental applications. Their arch-shaped design offers structural strength, while the FRP material ensures durability and resistance to corrosive environments.

Key Features

-

Korrosionsbeständigkeit: FRP materials are inherently resistant to a wide range of chemicals, making them ideal for harsh environments.

-

Leicht: Compared to traditional materials like steel, FRP is significantly lighter, facilitating easier transportation and installation.

-

Hohes Verhältnis von Festigkeit zu Gewicht: Despite being lightweight, FRP Arch Covers offer excellent structural strength, capable of withstanding various loads.environmental-expert.com

-

Geringer Wartungsaufwand: The durability of FRP reduces the need for frequent maintenance, leading to cost savings over the product's lifespan.

-

Design Flexibility: FRP can be molded into complex shapes, allowing for customized designs to meet specific project requirements.

Anwendungen

-

Kläranlagen: Covering open tanks to control odors and prevent contamination.

-

Chemical Processing Facilities: Providing containment and protection for chemical storage areas.

-

Agricultural Operations: Protecting feed storage and processing areas from environmental elements.

-

Industrial Manufacturing: Enclosing equipment or processes that require environmental isolation.

-

Öffentliche Infrastruktur: Used in pedestrian walkways or as protective covers in public spaces.

Construction and Materials

-

Materials: Typically constructed using a combination of polyester or vinyl ester resins reinforced with glass fibers.

-

Herstellungsprozess: FRP Arch Covers are often produced using molding techniques that ensure uniformity and structural integrity.

-

Oberflächenfinish: The exterior surface is usually coated with a gel coat that provides UV resistance and enhances durability.

-

Joint Design: Panels are designed with interlocking joints, often incorporating gaskets to ensure a weathertight and airtight seal.

-

Accessories: Available options include access hatches, vents, windows, and personnel doors, all customizable to project needs.environmental-expert.com+3Syntechnics Inc.+3environmental-expert.com+3

Technical Data Sheet (TDS)

| Eigentum | Typical Value | Testmethode |

|---|---|---|

| Zugfestigkeit | 12,000 psi (82.7 MPa) | ASTM D638 |

| Biegefestigkeit | 20,000 psi (137.9 MPa) | ASTM D790 |

| Druckfestigkeit | 17,000 psi (117.2 MPa) | ASTM D695 |

| Biegemodul | 0.9 x 10⁶ psi (6.2 GPa) | ASTM D790 |

| Thermal Expansion Coefficient | 10 x 10⁻⁶ /°F (18 x 10⁻⁶ /°C) |

|

| Specific Gravity | 1.5 |

|

| Flame Spread Rating | Class 1 (≤25) | ASTM E84 |

| Operating Temperature Range | -40°F to 180°F (-40°C to 82°C) |

|

Note: Values may vary based on specific resin systems and reinforcement configurations.

Entwurfsüberlegungen

-

Span and Load Requirements: Designs should account for live loads, wind loads, and any additional environmental factors.environmental-expert.com

-

Support Structures: FRP Arch Covers can be designed as self-supporting or may require additional structural support, depending on span and load.

-

Thermische Ausdehnung: Proper allowances should be made for thermal expansion and contraction to prevent structural issues.

-

Installation: Due to their lightweight nature, FRP Arch Covers can often be installed without heavy machinery, reducing installation time and costs.

Maintenance and Longevity

-

Reinigung: Regular cleaning with mild detergents helps maintain appearance and performance.

-

Inspektion: Periodic inspections are recommended to check for any signs of damage or wear.

-

Reparaturen: Minor damages can often be repaired on-site using compatible resin systems.

-

Service Life: With proper maintenance, FRP Arch Covers can have a service life exceeding 25 years.

Compliance and Standards

-

ASTM Standards: Manufactured to meet relevant ASTM standards for mechanical and fire performance.

-

Building Codes: Designs can be tailored to comply with local building codes and regulations.

-

Environmental Regulations: FRP materials are non-toxic and can be designed to meet environmental protection standards.

Anpassungsoptionen

-

Colors and Finishes: Available in various colors and textures to match aesthetic requirements.

-

Maße: Customizable to fit specific project dimensions and configurations.

-

Integration: Can be integrated with existing structures or systems, including HVAC and lighting.

FRP Arch Cover

Serie :

Proxy-Produkte >Anwendung

Pharmaceutical Industry: Antibiotics, insulin, enzymes, and probiotics. Food & Beverage Industry: Yogurt, kombucha, vinegar, beer, wine, soy sauce, pickles, and kimchi. Agriculture: Animal feed fermentation, silage, and biofertilizer production. Biotechnology: Bioethanol, biogas, bioplastics, algae, and microbial biomass production. Wastewater Treatment: Anaerobic digestion for methane production. Distilleries: Alcohol and spirit fermentation using molasses, grains, or fruits.

Material :

FRP

Typ :

FRP (Fiberglass Reinforced Plastic) fermentation tanks

FAQ

Q :

What are the main applications of FRP Arch Covers?

A :

Wastewater treatment tanks Chemical processing tanks Sludge digesters Agricultural pits and feed storage Odor control enclosures Equipment protection in corrosive environments

Q :

What are the advantages of using FRP instead of metal or concrete covers?

A :

Corrosion Resistance: Ideal for acidic or chemical environments Lightweight: Easier to transport and install High strength-to-weight ratio Low maintenance UV and weather resistant Long service life (20–30+ years)

Q :

What shapes and sizes are available?

A :

FRP Arch Covers can be: Modular or custom-sized Single span or multi-span Designed to span up to 8–10 meters unsupported (depending on thickness and profile) Flat, domed, or curved depending on customer needs

Q :

Can FRP Arch Covers be walked on?

A :

Yes — many FRP covers are engineered for pedestrian or light equipment traffic, but the design load capacity must be confirmed before use. Some covers include anti-slip surfacing for safety.

Q :

Are FRP Arch Covers airtight or odor-tight?

A :

Yes, with proper installation using gasketed joints, sealants, and locking systems, FRP arch covers can achieve excellent odor containment and weatherproof sealing.

Q :

Are FRP Arch Covers resistant to UV radiation and weathering?

A :

Absolutely. Most FRP covers are coated with UV-resistant gel coats or vinyl ester resins, offering excellent resistance to long-term sunlight exposure, rain, and temperature changes.

Andere verwandte Produkte