Ein FRP Denitrification Tower is a specialized gas treatment system designed to remove nitrogen oxides (NOₓ) from industrial exhaust gases using chemical absorption or catalytic reduction. These towers are constructed from Glasfaserverstärkter Kunststoff (GFK) for their outstanding corrosion resistance, structural integrity, and long-term durability in chemically aggressive environments.

Einführung zur Produktleistung

Denitrification towers are essential in steel manufacturing, waste incineration, power plants, fertilizer production, chemical synthesis, and other industries where NO and NO₂ gases are generated. These towers play a vital role in achieving environmental compliance with national and international NOₓ emission regulations, including EPA, EU standards, Und local air quality management laws.

Depending on the process, denitrification towers may operate through wet scrubbing, selective catalytic reduction (SCR), oder selective non-catalytic reduction (SNCR) mechanisms. FRP is particularly suited to wet scrubbing applications where acidic or oxidizing solutions such as H₂O₂, NaOH, oder KMnO₄ are used to neutralize NOₓ.

Key Features

-

Korrosionsbeständigkeit: Handles oxidizing, acidic, and alkaline environments with superior durability.

-

High Removal Efficiency: Up to 95–98% NOₓ removal with optimized reagent dosing and tower design.

-

Custom Engineered: Designed per emission load, gas flow rate, and temperature for optimal treatment.

-

Leichtbau: Easier handling and reduced installation cost vs. metal alternatives.

-

Long Service Life: FRP life expectancy ranges from 15 to 25 years with minimal maintenance.

Working Principle (Wet Scrubbing)

-

Exhaust gas enters the lower inlet of the tower.

-

Liquid oxidizing agent (e.g., NaClO₂, H₂O₂, or KMnO₄) is sprayed downward through spray nozzles.

-

The NO and NO₂ are absorbed and oxidized into HNO₃ or NO₃⁻ compounds in the packing section.

-

Cleaned gas passes through the mist eliminator and exits through the exhaust stack.

-

Absorbent liquid is recirculated via a chemical-resistant pump.

Typical Applications

-

Waste incineration plants

-

Chemical fertilizer production

-

Nitric acid production units

-

Steel mills and foundries

-

Glass manufacturing

-

Thermal power generation

-

Pharmaceutical plants

Technical Data Sheet (TDS) – FRP Denitrification Tower

| Parameter | Spezifikation |

|---|---|

| Material of Construction | FRP (Isophthalic, Vinyl Ester, Bisphenol-A resins based on chemistry) |

| Structure Type | Vertical cylindrical tower with flanged connections |

| Tower Diameter | 500 mm – 4000 mm (custom sizes available) |

| Design Flow Rate | 1,000 m³/hr to 100,000+ m³/hr |

| Removal Efficiency | 85–98% NOx removal (with proper chemical or catalytic process) |

| Scrubbing Liquid | NaOH + NaClO₂, H₂O₂, KMnO₄, NaHSO₃ (adjustable per application) |

| Packing Material | PP / PVC Pall Rings, Raschig rings, or structured plastic packing |

| Mist Eliminator | Chevron blade or mesh pad (PP, FRP) |

| Recirculation Pump | PP / FRP / SS316, chemical-resistant centrifugal pump |

| Temperature Range | 20–70°C (standard); up to 120°C with high-temp resin options |

| pH Range (operation) | 5 – 10 (depending on scrubbing agent) |

| Coating Thickness | 3–6 mm inner liner with corrosion barrier + structural FRP layers |

| UV-Beständigkeit | Yes, with gelcoat or pigmented resin exterior |

| Design Pressure | ± 200 mmWC (standard); higher pressure ratings available on request |

| Blower Material | FRP / PP / MS-FRP lined with corrosion coating |

| Noise Level | < 75 dB(A) at 1 m |

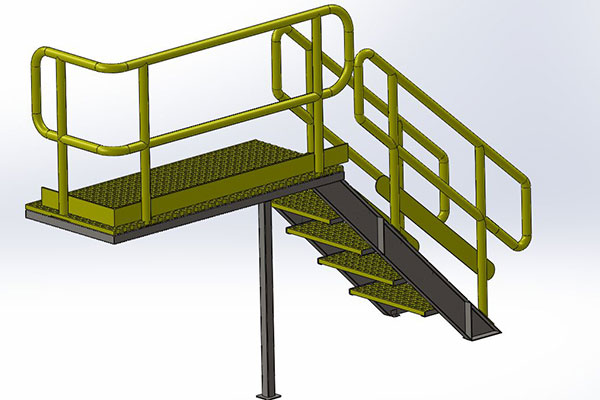

| Inspection Openings | Side manholes, top cover access, drain ports |

| Maintenance Cycle | Quarterly inspections; semi-annual chemical cleaning |

| System Lifespan | 15–25 years |

| Zertifizierungen | ISO 9001, EPA/CPCB compliance, CE mark, optional ATEX for explosive zones |

Standard Inclusions

-

FRP Denitrification tower body

-

Demister unit (FRP or PP)

-

Nozzle array and spray header

-

Recirculation pump and piping

-

Instrumentation ports (for pH, ORP, level sensors)

-

Chemical dosing ports

-

Access doors and drain connections

Optional Add-ons

-

PLC-based automatic control system

-

pH and NOₓ sensor integration

-

Stainless steel or lined blowers

-

Flame-retardant resin (ASTM E84 compliant)

-

Stack with bird cage and lightning arrestor

-

Skid-mounted integrated systems

Packaging & Delivery

-

Verpackung: Wooden crate, bubble wrap, or shrink film as per export standards

-

Lead Time: 4–6 weeks depending on project scope

-

Lieferung: Worldwide shipping with on-site installation support available

FRP Denitrification Tower

Serie :

Produkte >Anwendung

Chemical processing plants Wastewater treatment facilities Laboratories and chemical research centers Pulp and paper industry Semiconductor and electronics production Food processing and odor control Pharmaceutical manufacturing

Markenname :

TF-Verbundwerkstoff

Produktname :

FRP Purification Tower

FAQ

Q :

What is an FRP Purification Tower?

A :

An FRP Purification Tower is a vertical or horizontal tower system made of Fiberglass Reinforced Plastic (FRP) used to purify and treat industrial exhaust gases by removing harmful contaminants such as acid fumes, alkaline vapors, ammonia, chlorine, sulfur compounds, and odors. It operates using wet scrubbing, chemical absorption, or other neutralization methods.

Q :

What gases can an FRP Purification Tower remove?

A :

Acidic gases: HCl, H₂SO₄ mist, SO₂, Cl₂ Alkaline gases: NH₃ Organic compounds: VOCs (when combined with bio or carbon filters) Corrosive vapors: HF, HBr, NOₓ Odorous gases: H₂S, mercaptans

Q :

Why use FRP instead of steel or PVC?

A :

Excellent corrosion resistance Longer service life (15–25 years) Resistant to acids, alkalis, oxidants, and saltwater Lightweight and easy to install Lower maintenance costs Suitable for outdoor and marine environments

Q :

How does an FRP Purification Tower work?

A :

Polluted gas enters the tower through the inlet. The gas passes upward (countercurrent) through scrubbing media. A liquid (usually water or a chemical solution) is sprayed downward. Pollutants are absorbed or neutralized in the scrubbing section. Clean air exits through the demister and stack.

Andere verwandte Produkte