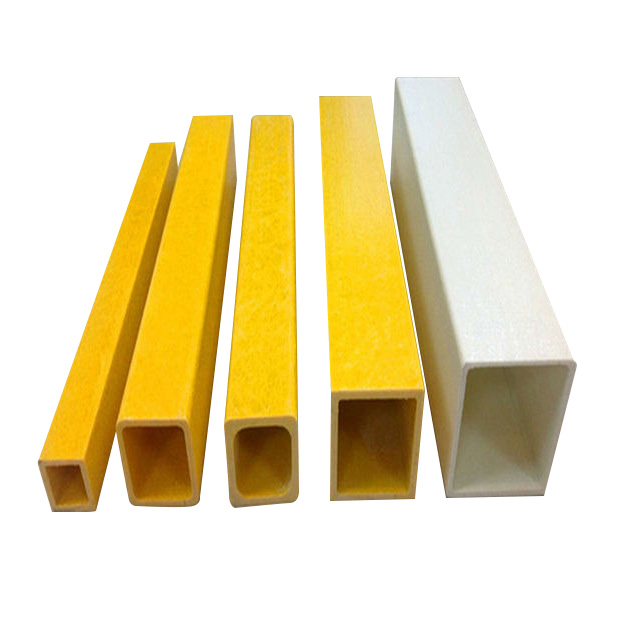

A GRP (Glass Reinforced Plastic) Channel, also known as an FRP (Fiberglass Reinforced Plastic) Channel, is a structural profile made from high-strength glass fibers embedded in a polymer resin matrix. It is manufactured through the pultrusion process, ensuring uniform quality, high durability, and excellent corrosion resistance.

Einführung zur Produktleistung

1. What is a GRP Channel?

GRP Channels are widely used in construction, industrial frameworks, marine applications, electrical installations, and chemical plants, where lightweight, non-corrosive, and high-strength materials are required.

2. Conventional Specifications & Dimensions

GRP Channels are typically available in U-shaped or C-shaped profiles with different thicknesses for varying load requirements.

Common Dimensions (mm & inches)

| Size (mm) | Flange Width (mm) | Web Thickness (mm) | Size (inches) | Flange Width (inches) | Web Thickness (inches) |

|---|---|---|---|---|---|

| 50 x 25 | 5, 6 | 3, 4 | 2" x 1" | 0.20", 0.24" | 0.12", 0.16" |

| 75 x 40 | 5, 6 | 4, 5 | 3" x 1.5" | 0.20", 0.24" | 0.16", 0.20" |

| 100 x 50 | 6, 8 | 5, 6 | 4" x 2" | 0.24", 0.31" | 0.20", 0.24" |

| 150 x 75 | 6, 8, 10 | 5, 6, 8 | 6" x 3" | 0.24", 0.31", 0.39" | 0.20", 0.24", 0.31" |

| 200 x 100 | 8, 10, 12 | 6, 8, 10 | 8" x 4" | 0.31", 0.39", 0.47" | 0.24", 0.31", 0.39" |

📌 Standard Lengths: 3m, 6m, 12m (custom lengths available)

📌 Custom sizes and special reinforcements are available upon request.

Materialzusammensetzung

GRP Channels are made using:

-

Glasfaserverstärkung – Provides high tensile strength.

-

Polymer Resin Matrix – Ensures chemical resistance and durability.

📌 Common Resin Types:

-

Polyester – Cost-effective, general-purpose.

-

Vinylester – Excellent chemical and corrosion resistance.

-

Phenol – Fire-resistant, low smoke emission.

-

Epoxy – High mechanical strength, impact-resistant.

Farboptionen

-

Standard Colors: Gray, Green, Yellow, Red, Black

-

Custom colors available upon request.

3. Key Advantages of GRP Channels

| Besonderheit | GRP Channel | Steel Channel | Aluminum Channel |

|---|---|---|---|

| Korrosionsbeständigkeit | ✅ Excellent (Resists chemicals, moisture, saltwater) | ❌ Prone to rust | ⚠️ Corrosion-resistant but may oxidize |

| Gewicht | ✅ Lightweight (~75% lighter than steel) | ❌ Heavy | ✅ Lighter than steel but heavier than GRP |

| Strength-to-Weight Ratio | ✅ High | ✅ High | ✅ High |

| Electrical Insulation | ✅ Non-conductive | ❌ Conductive | ❌ Conductive |

| Thermal Conductivity | ✅ Low (Good insulation) | ❌ High (conducts heat) | ⚠️ Medium |

| Maintenance | ✅ Low maintenance | ❌ Requires painting/coating | ✅ Low maintenance |

| Installation | ✅ Easy (can be cut & drilled on-site) | ❌ Requires welding, heavy tools | ✅ Moderate |

| Lifespan | ✅ 20+ years | ❌ Subject to corrosion | ✅ 10–15 years |

📌 Key Takeaways

-

GRP Channels are rust-proof and corrosion-resistant, making them ideal for outdoor and industrial applications.

-

They are lightweight yet strong, reducing installation and transportation costs.

-

They provide insulation from electricity and heat, making them safe for electrical applications.

-

They require minimal maintenance, leading to long-term cost savings.

4. Applications of GRP Channels

GRP Channels are widely used across different industries:

🏗 Construction & Infrastructure – Structural supports, handrails, cable trays.

⚡ Electrical Industry – Cable management systems, transformer supports.

🌊 Marine & Offshore – Decking frames, boat structures, seawater-resistant installations.

🏭 Chemical Plants & Wastewater Facilities – Non-corrosive structural frameworks.

🚆 Transport – Lightweight yet durable framing components.

🌿 Agriculture & Greenhouses – Corrosion-resistant structural elements.

5. Installation & Processing

Can GRP Channels be cut and drilled?

Yes! GRP Channels can be easily cut, drilled, and machined using:

-

Circular saws with diamond/tungsten carbide blades

-

Drills with HSS (High-Speed Steel) bits

-

Angle grinders for smooth finishing

💡 Tip: Always use dust extraction or wear a mask when cutting GRP to avoid inhaling fine fiberglass dust.

Installation Methods:

-

Bolts & Fasteners – Pre-drilled holes make installation simple.

-

Adhesives & Bonding Agents – Can be used for seamless joints.

-

Brackets & Clamps – For flexible mounting and structural connections.

6. Fire Resistance of GRP Channels

GRP Channels can be fire-retardant depending on the resin used:

🔥 Standard Polyester Resin – Basic fire resistance.

🔥 Vinylesterharz – Moderate fire resistance.

🔥 Phenolharz – High fire resistance, low smoke emissions, suitable for public spaces.

📌 Always check fire safety regulations before selecting a resin type.

7. Cost Considerations

The cost of GRP Channels depends on:

💰 Size & thickness

💰 Resin type (Standard polyester is cheaper; phenolic is premium)

💰 Quantity ordered (Bulk orders receive better pricing)

💰 Anpassung (Color, length, fire-retardant versions, etc.)

📌 While the initial cost is higher than steel, GRP requires lower maintenance, making it cost-effective in the long run.

8. Lifespan & Maintenance

⏳ Lifespan: 20+ years in normal conditions.

🧼 Wartung:

-

Regular cleaning – Use water and mild detergent.

-

Check for physical damage – Especially in high-load applications.

-

UV Protection (if needed) – Optional coatings can be applied.

Abschluss

GRP Channels are an ideal replacement for steel and aluminum in applications requiring corrosion resistance, lightweight strength, and durability. They are perfect for industrial, marine, construction, and electrical applications.

💡 Need a quotation or technical consultation? Let me know your project requirements! 🚀

GRP Channel

Serie :

Hauptprodukte >Anwendung

🏗 Construction & Infrastructure – Structural supports, handrails, cable trays. ⚡ Electrical Industry – Cable management systems, transformer supports. 🌊 Marine & Offshore – Decking frames, boat structures, seawater-resistant installations. 🏭 Chemical Plants & Wastewater Facilities – Non-corrosive structural frameworks. 🚆 Transportation – Lightweight yet durable framing components. 🌿 Agriculture & Greenhouses – Corrosion-resistant structural elements.

Markenname :

TF-Verbundwerkstoff

Produktname :

GRP Channel

Material :

Glasfaser

Farbe :

Yellow,Gray,Other

FAQ

Q :

Can GRP Channels be customized?

A :

Yes! GRP Channels can be customized in: 📌 Size & Thickness 📌 Resin Type (Fire-resistant, Chemical-resistant, etc.) 📌 Color 📌 Length

Q :

How do GRP Channels perform in extreme temperatures?

A :

🌡️ Operating Temperature Range: -50°C to +120°C (depends on resin type). 🌞 UV-resistant versions available for outdoor use.

Q :

Can GRP Channels be used underwater?

A :

Yes! GRP Channels are highly resistant to water and salt corrosion, making them perfect for marine and offshore applications.

Q :

Do GRP Channels meet international standards?

A :

Yes, GRP Channels comply with: ✅ ISO 9001 (Quality Management) ✅ EN 13706 (GRP Structural Profiles) ✅ ASTM D4385 (Pultruded GRP Standards) ✅ BS 476 (Fire Resistance Tests)

Q :

Can I use GRP Channels in place of metal channels?

A :

Yes! GRP Channels are a great alternative to steel and aluminum in applications requiring corrosion resistance, lightweight strength, and electrical insulation.

Q :

Where can I buy GRP Channels?

A :

GRP Channels are available from industrial suppliers, construction material distributors, and specialized FRP manufacturers.Contact us!

Andere verwandte Produkte