Our GRP handrail system often used in a GRP handrail or guardrail to continue the middle rail on a 90° corner or connect vertical posts to the top rail, or to join the midrail to the end post.

Product performance introduction

|

|

The GRP external Swivel is a versatile in-line swivel fitting, often used where angles vary on slops, steps and landings. |

|

The GRP 116 Mid Corner is a 90° corner joint, often used in a GRP handrail or guardrail to continue the middle rail on a 90° corner, but can also be used to build rectangular or square structures. The upright passes vertically through the GRP fitting. Often used with the GRP-128 Top Corner. |

|

|

The GRP 101 Short Tee is a 90° tee connection, typically used in a GRP handrail to connect vertical posts to the top rail, or to join the midrail to the end post. The tube cannot be joined within the top of the fitting-the GRP-104 Long Tee can be used as an alternative if this is required. |

|

The GRP Fitting 119 Midrail Cross is a 90° joint, often used to join the middle rail to an intermediate upright post in a GRP handrail or guardrail. The upright passes vertically through the GRP fitting. |

|

|

The GRP 104 Long Tee is a 90° tee connection, typically used to connect vertical posts to the top rail of a GRP handrail. The GRP -104 can be used where two lengths of tube need to be joined within the top of the fitting. |

|

The GRP 125 fitting is a 90° elbow, often used in a GRP handrail or guardrail to connect the top rail to the upright post at the end of a run. |

|

|

The GRP 129 is a 30° tee fitting, often used in a staircase GRP handrail or guardrail. |

|

The 128 Top Corner fitting is a 3-way. 90° elbow, typically used to join an upright post to the top rail of a GRP handrail on a 90º corner. Often used with the GRP-116 Mid Corner. |

|

|

The GRP 130 is a 30° Cross, often used to connect the midrail to intermediate posts in a staircase GRP handrail. |

|

The GRP 116 Mid Corner is a 90° corner joint, often used in a GRP handrail or guardrail to continue the middle rail on a 90° corner, but can also be used to build rectangular or square structures. The upright passes vertically through the GRP fitting. Often used with the GRP-128 Top Corner. |

|

|

The GRP 132 Base Plate is a base flange with four fixing holes, used to fix down the upright posts in a handrail or guardrail. |

|

The GRP 173 Single Swivel is a versatile swivel fitting, used where angles vary on slopes, steps and landings. |

|

|

The 145 Wall Socket is a GRP Fitting designed for side fixing GRP handrails or guardrails to walls, ramps and steps. |  |

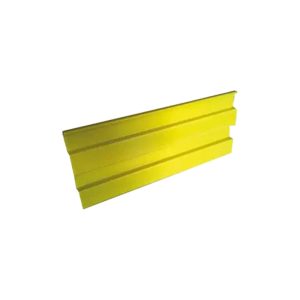

Our GRP Kick plate is 100mm wide, with a 5mm wall. It is stocked in 6m lengths but can be cut to length if required. |

Made in China glass reinforced plastic (GRP),TFcomposite’s GRP handrail system offers key benefits over steel that explain why you’ll see GRP handrailing everywhere from water treatment works to the rail industry.

Fiberglass Reinforced Plastic (FRP) handrail systems are advanced, durable solutions for safety and access in industrial, commercial, and architectural applications. They are valued for their strength, corrosion resistance, and low maintenance, making them ideal for environments where traditional materials like steel or wood might fail due to exposure to harsh elements. Below is an in-depth exploration of FRP handrail systems, their components, benefits, applications, installation processes, and maintenance.

1. What is an FRP Handrail System?

An FRP handrail system is a modular or pre-engineered safety barrier system made from fiberglass reinforced plastic, a composite material that combines strong fibers with a polymer matrix. This results in a product that is lightweight, strong, and resistant to corrosion, chemicals, and UV exposure.

Key Components

FRP handrail systems typically consist of:

- Rails: The horizontal components providing continuous support.

- Posts: Vertical elements anchored to the ground or structure to support the rails.

- Knee Rails: Secondary horizontal rails for additional support and safety.

- Toe Boards: Base-level components to prevent tools or debris from falling.

- Fittings: Connectors, brackets, and fasteners that hold the system together.

- Bases and Mounts: Used to anchor the system to floors, walls, or other surfaces.

2. Materials and Manufacturing

FRP handrail systems are produced using two main manufacturing methods:

- Pultrusion:

- Continuous fibers are pulled through a resin bath and a heated die.

- Ensures uniform strength and a smooth finish.

- Molding:

- Fiberglass mats or woven roving are layered and infused with resin in a mold.

- Often used for complex or custom shapes.

Common Materials in FRP Handrails

- Fibers: Typically glass fibers for high tensile strength.

- Resin Types:

- Polyester: Cost-effective and moderately resistant to chemicals.

- Vinyl Ester: Higher resistance to chemicals and heat.

- Epoxy: Superior mechanical strength and adhesion.

Additives like UV inhibitors, fire retardants, and pigments can be incorporated to enhance performance and aesthetics.

3. Key Benefits of FRP Handrail Systems

FRP handrail systems offer several advantages over traditional materials:

3.1. Corrosion Resistance

- Ideal for environments exposed to chemicals, saltwater, or moisture.

- Used in wastewater plants, marine applications, and chemical processing facilities.

3.2. Lightweight and Easy Installation

- Weighs significantly less than steel or aluminum, reducing transportation and labor costs.

- Modular designs often allow for easy assembly without specialized tools.

3.3. High Strength-to-Weight Ratio

- Provides comparable or superior strength to traditional materials with less bulk.

3.4. Durability and Longevity

- Resists cracking, warping, and degradation over time.

- Long service life even in extreme conditions.

3.5. Low Maintenance

- Requires no painting or frequent inspections.

- Resistant to rust and biological growth.

3.6. Electrical and Thermal Insulation

- Non-conductive, making it safe for electrical environments.

- Low thermal conductivity reduces the risk of burns in high-temperature areas.

3.7. Customizability

- Available in various colors, sizes, and configurations to suit specific requirements.

- Aesthetic options enhance compatibility with architectural designs.

4. Applications of FRP Handrail Systems

FRP handrails are used across diverse industries due to their adaptability and robust properties. Below are examples of key application areas:

4.1. Industrial Facilities

- Chemical Plants: Withstand chemical splashes and fumes.

- Oil and Gas: Non-corrosive properties ensure longevity in offshore and onshore facilities.

- Power Plants: Non-conductive properties provide safety in electrical substations.

4.2. Water and Wastewater Treatment Plants

- Resistant to chlorine, acids, and moisture.

- Ideal for walkways, platforms, and tank access.

4.3. Marine and Coastal Environments

- Unaffected by saltwater corrosion.

- Used on docks, piers, and offshore platforms.

4.4. Public Infrastructure

- Bridges, parks, and pedestrian walkways where safety and aesthetics are essential.

4.5. Commercial and Residential

- Balconies, staircases, and ramps requiring modern, low-maintenance railings.

5. Design Standards and Compliance

FRP handrail systems are often designed to meet rigorous safety and engineering standards, including:

-

OSHA (Occupational Safety and Health Administration):

- Ensures compliance with workplace safety guidelines for handrails.

- Requires specific height, strength, and deflection properties.

-

ASTM (American Society for Testing and Materials):

- Provides testing standards for strength, durability, and material performance.

-

ISO (International Organization for Standardization):

- Covers quality and environmental safety standards globally.

-

ADA (Americans with Disabilities Act):

- Mandates handrail accessibility features, such as smooth surfaces and appropriate height.

6. Installation of FRP Handrail Systems

Installing an FRP handrail system involves the following steps:

6.1. Preparation

- Assess site conditions and ensure the surface is clean and level.

- Mark installation points based on a pre-approved layout or engineering design.

6.2. Assembly

- Install base mounts or brackets at marked points.

- Attach posts to the base mounts using bolts or adhesives.

- Secure horizontal rails and knee rails to the posts using brackets and fasteners.

- Attach toe boards if required.

6.3. Finishing

- Tighten all connections and inspect for alignment.

- Apply sealants or coatings if additional protection is needed.

6.4. Safety Testing

- Perform load tests to ensure compliance with safety standards.

- Inspect for any loose connections or misalignments.

7. Maintenance of FRP Handrail Systems

FRP systems require minimal upkeep, but periodic checks can ensure maximum performance:

7.1. Cleaning

- Use mild soap and water to remove dirt, debris, or grease.

- Avoid abrasive materials to prevent surface scratching.

7.2. Inspection

- Check for loose fittings, bolts, or cracks in the material.

- Inspect joints and connections regularly.

7.3. Repairs

- Damaged components can often be replaced individually without dismantling the entire system.

- Use compatible adhesives or replacement parts from the manufacturer.

8. Customization Options

FRP handrail systems are highly customizable, allowing for adaptation to specific needs:

- Colors: Yellow, green, grey, or custom colors for branding or safety coding.

- Sizes: Varying rail diameters and post heights to meet specific requirements.

- Surface Finishes:

- Smooth for aesthetic purposes.

- Textured for slip resistance.

9. Cost Considerations

While the initial cost of FRP handrails may be higher than traditional materials, their long-term cost-effectiveness makes them an attractive option. Key cost factors include:

- Material grade (polyester vs. vinyl ester).

- Customization requirements.

- Installation complexity.

- Quantity and scale of the project.

10. FRP Handrail System vs. Traditional Materials

| Feature | FRP Handrails | Steel Handrails | Aluminum Handrails |

|---|---|---|---|

| Corrosion Resistance | Excellent | Poor | Moderate |

| Weight | Lightweight | Heavy | Lightweight |

| Maintenance | Low | High | Moderate |

| Strength | High | Very High | Moderate |

| Electrical Conductivity | Non-conductive | Conductive | Conductive |

| Cost (Initial) | Moderate to High | Low to Moderate | High |

| Cost (Lifetime) | Low | High | Moderate |

11. Future Trends

- Enhanced Aesthetics: New pigments and coatings for modern designs.

- Sustainability: Use of recycled or eco-friendly resins.

- Smart Systems: Integration of IoT sensors for safety monitoring.

Conclusion

FRP handrail systems are a superior choice for industries and environments requiring durability, safety, and low maintenance. Their adaptability and performance advantages over traditional materials make them a long-term investment for infrastructure and industrial facilities. By leveraging their modular design, ease of installation, and customization capabilities, FRP handrails continue to gain prominence in diverse applications.

Detailed Overview of FRP Handrail Systems

Series :

Main Products >application

Our GRP handrail system is widely used in GRP handrail and guardrail's multi-drop-and-continue cross-connection.

Brand name :

TFcomposite

Color :

yellow or grey

FAQ

Q :

What size and length does the GRP handrail tube come in?

A :

The GRP tube is only produced in 50mm o/d (outside diameter) and is stocked in 5m lengths. We can cut the tube down to length if needed.

Q :

How are the fittings fixed to the tube?

A :

Fittings for GRP handrails are supplied as two identical halves which simply clamp together around the tubing. These need to be drilled onsite using a standard 9mm diameter HSS drill bit (supplied with your order) and bolted together with the special stainless steel rivnut fixings provided. The bolts are then inserted and tightened using a pozi 3 driver, the knurled rivnut fixing will hold in place whilst the bolt is tightened. These fixings provide a flush finish with no protruding bolt heads.

Q :

What colours are available for GRP handrail systems?

A :

We stock the tube and fittings in yellow – for high visibility – or grey.

Other related products