Epoxy resin is a type of synthetic polymer that is created by mixing two components - a resin and a hardener. When these two components are mixed together, a chemical reaction occurs, resulting in a hard, durable material that is resistant to heat, chemicals, and other forms of wear and tear. It is known for its high strength, durability, and versatility, and is often used in industrial, commercial, and DIY settings.

Product performance introduction

Epoxy Resin

Product Description:

Our Epoxy Resin is a high-performance, two-component epoxy resin system that offers exceptional mechanical strength, chemical resistance, and electrical insulation properties. This system is ideal for a wide range of industrial applications, including aerospace, electronics, and industrial manufacturing.

Key Features:

- High-Strength and Rigidity: Our Epoxy Resin exhibits excellent mechanical strength, with a tensile strength of ≥ 80 MPa and a flexural strength of ≥ 120 MPa.

- Excellent Chemical Resistance: This epoxy resin system offers superior chemical resistance to a wide range of chemicals, including acids, alkalis, and organic solvents.

- Good Electrical Insulation: Our Epoxy Resin has excellent electrical insulation properties, with a dielectric strength of ≥ 15 kV/mm and a volume resistivity of ≥ 10^12 Ohm·cm.

- Low Shrinkage: The epoxy resin system exhibits low shrinkage, with a volumetric shrinkage of ≤ 2%, ensuring minimal warping and dimensional change after curing.

- Good Adhesion: Our Epoxy Resin has excellent adhesion to a variety of substrates, including metals, ceramics, and glass.

Technical Specifications:

- Resin:

- Viscosity (at 25°C): 5,000 - 10,000 mPa·s

- Density (at 25°C): 1.1 - 1.2 g/cm³

- Hardener:

- Viscosity (at 25°C): 1,000 - 2,000 mPa·s

- Density (at 25°C): 0.9 - 1.0 g/cm³

- Cured Properties:

- Tensile Strength: ≥ 80 MPa

- Flexural Strength: ≥ 120 MPa

- Compressive Strength: ≥ 100 MPa

- Dielectric Strength: ≥ 15 kV/mm

- Volume Resistivity: ≥ 10^12 Ohm·cm

- Glass Transition Temperature (Tg): ≥ 120°C

Mixing Ratio:

- Hardener to Resin: 1:1 (weight ratio)

- Mixing Time: 5-10 minutes

Applications:

- Aerospace: Our Epoxy Resin is suitable for use in aerospace applications, including aircraft components, satellite components, and rocket components.

- Electronics: This epoxy resin system is ideal for use in electronic applications, including printed circuit boards, computers, and communication devices.

- Industrial Manufacturing: Our Epoxy Resin can be used in a variety of industrial manufacturing applications, including machinery components, electrical components, and construction materials.

Safety and Handling:

- Use protective gloves and eyewear when handling the epoxy resin system.

- Ensure good ventilation in the working area.

- Keep away from heat sources and open flames.

Packaging:

- Epoxy Resin: 5 kg or 20 kg (container)

- Hardener: 5 kg or 20 kg (container)

- Packaging: Individual containers are wrapped in plastic film and packaged in cartons.

Epoxy Resin

Series :

Proxy Products >application

coatings, adhesives, and composites

Product name :

Epoxy Resin

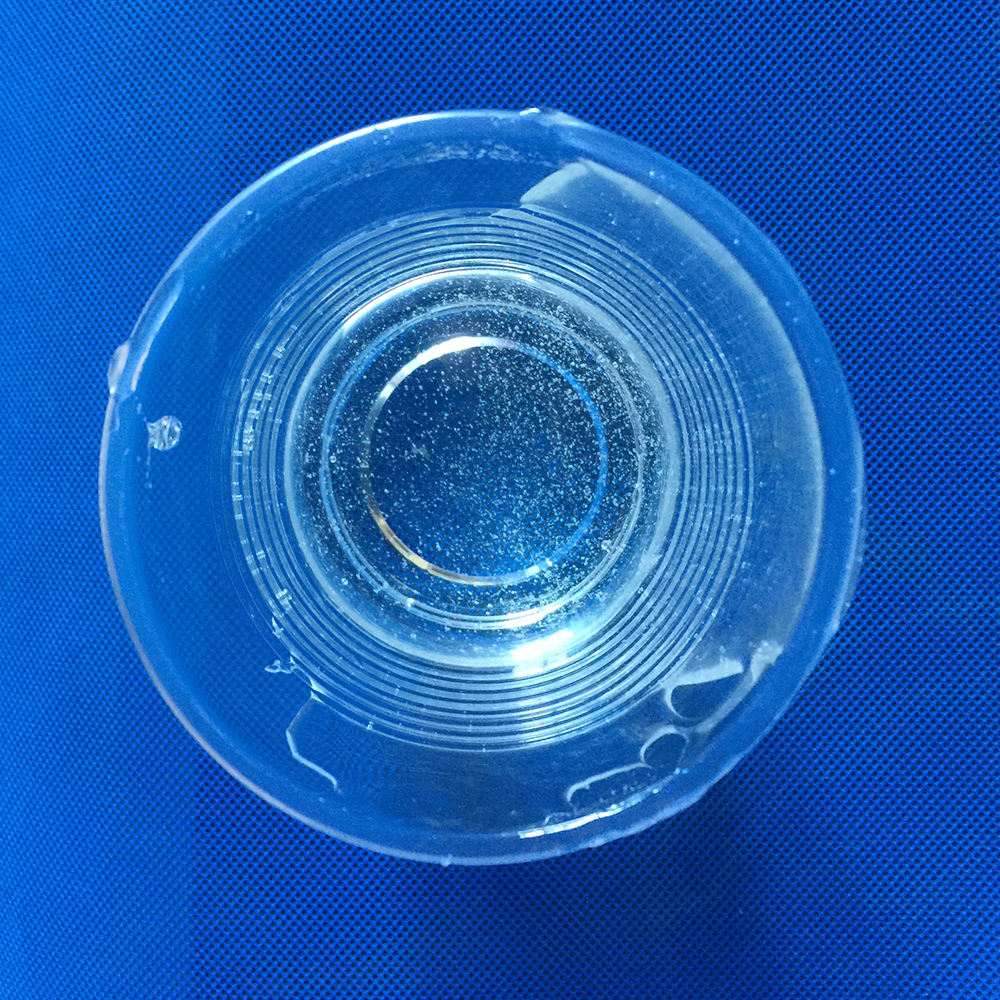

Appearance :

Clear liquid, no visible mechanical impurity

FAQ

Q :

How do you store polyester resin?

A :

It should be stored in a cool, dry place, away from direct sunlight and sources of heat. It is also important to keep the container tightly sealed when not in use.

Q :

What is the shelf life of epoxy resin?

A :

In general, unopened containers of polyester resin can be stored for 6-12 months from date of manufacture.

Other related products