Fiberglass stair treads and stair covers are an essential complement to molded and pultruded grating installations.

Introducción al rendimiento del producto

Pultruded Fiber Reinforced Polymer (FRP) stair treads represent a cutting-edge solution for safe and durable access in industrial, commercial, and residential environments. These treads are manufactured using the pultrusion process, which produces continuous lengths of composite material with consistent cross-sections and high structural integrity. Designed to meet stringent safety and performance standards, pultruded FRP stair treads offer exceptional strength, corrosion resistance, and versatility, making them ideal for both indoor and outdoor applications.

1. Material Composition

Pultruded FRP stair treads are constructed using advanced composite materials, ensuring exceptional performance in demanding environments. The primary components include:

- Refuerzo de fibra de vidrio: Fiberglass rovings and mats are used for structural strength and dimensional stability.

- Resin Systems: Resins such as polyester, vinyl ester, or epoxy provide chemical resistance, moisture protection, and thermal stability.

- Surface Grit: Embedded quartz or aluminum oxide grit offers excellent slip resistance, ensuring safety in wet or oily conditions.

- UV Inhibitors: Optional additives protect against sunlight-induced degradation for outdoor applications.

- Fire Retardants: Meets fire safety standards through the addition of flame-retardant materials during production.

2. Pultrusion Manufacturing Process

Pultruded FRP stair treads are produced through a continuous process known as pultrusion. This process ensures a high degree of consistency, structural integrity, and customization. The steps include:

- Fiberglass Reinforcement Preparation: Continuous strands of fiberglass rovings are pulled through a resin bath for impregnation.

- Resin Infusion: Fiberglass is coated with resin and passed through a heated die, where it is shaped into the desired profile.

- Curing and Solidification: The material is heated within the die to cure the resin, resulting in a rigid and strong composite.

- Cutting and Finishing: The cured profiles are cut to specified lengths and finished to meet specific application requirements.

3. Key Features of Pultruded FRP Stair Treads

- Superior Strength-to-Weight Ratio: Pultruded FRP stair treads provide remarkable strength while remaining lightweight, reducing installation labor and structural load.

- Resistencia a la corrosión: Engineered to withstand harsh chemicals, saltwater, and moisture, they are perfect for marine, industrial, and wastewater environments.

- Resistencia al deslizamiento: An anti-slip surface embedded with grit ensures safety in environments prone to spills, rain, or debris.

- Resistencia al fuego: Manufactured to meet fire safety standards, they resist ignition and reduce flame spread.

- UV Stability: Optional UV inhibitors protect against sun damage, maintaining the appearance and functionality over time.

- Long Lifespan: Highly durable and resistant to wear and tear, pultruded FRP treads can last for decades with minimal maintenance.

- Personalización: Available in a variety of sizes, colors, and finishes to meet the unique requirements of different industries.

4. Applications

Pultruded FRP stair treads are versatile and suitable for a wide range of applications, including:

- Industrial: Chemical plants, oil refineries, and factories where exposure to corrosive substances is common.

- Marina y Offshore: Docks, ship decks, and offshore platforms requiring resistance to saltwater and moisture.

- Plantas de tratamiento de aguas residuales: Ideal for environments exposed to chemicals, moisture, and microbial growth.

- Comercial: Parking garages, shopping malls, and office buildings needing low-maintenance and aesthetically pleasing solutions.

- Infraestructura pública: Bridges, railway platforms, and pedestrian overpasses benefit from their strength and slip resistance.

- Residencial: Outdoor decks, pool areas, and garden staircases for long-lasting and safe access solutions.

5. Types of Pultruded FRP Stair Treads

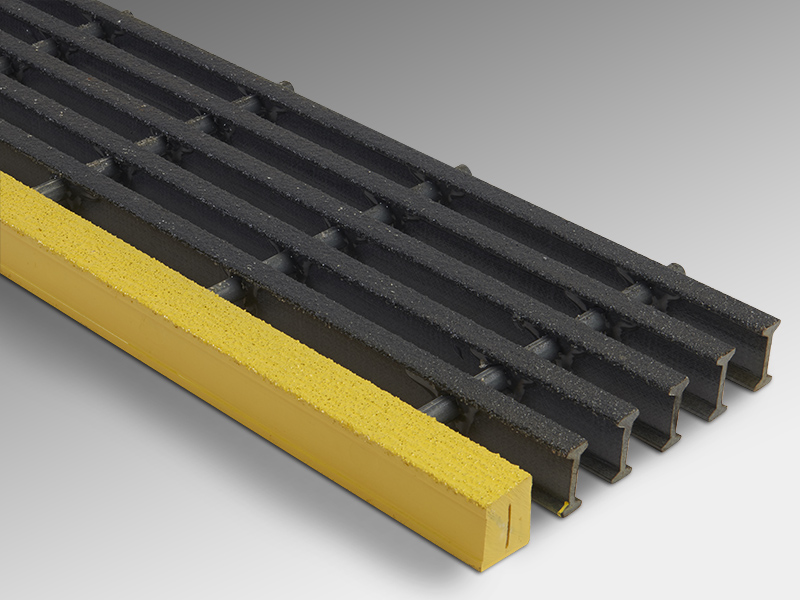

-

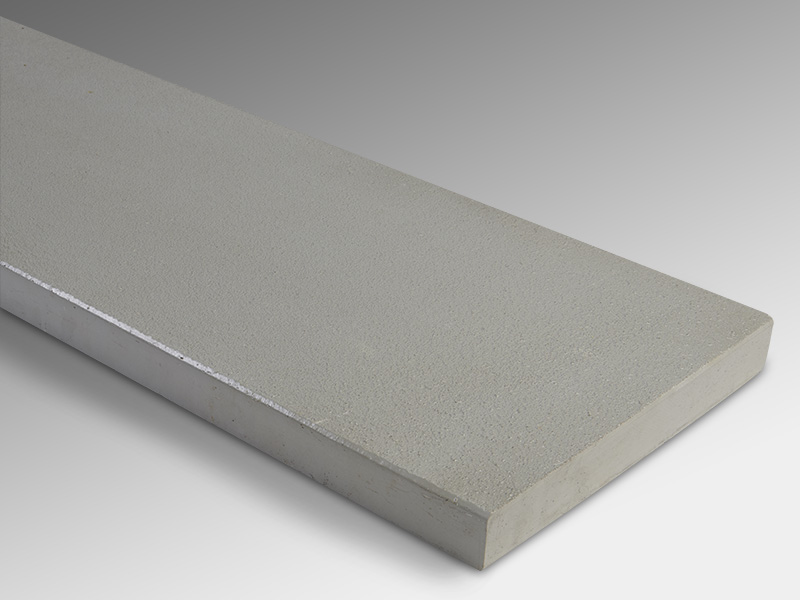

Standard Pultruded Stair Treads:

- Feature an open mesh or grid-like design for drainage and ventilation.

- Suitable for environments where debris or liquids need to pass through.

-

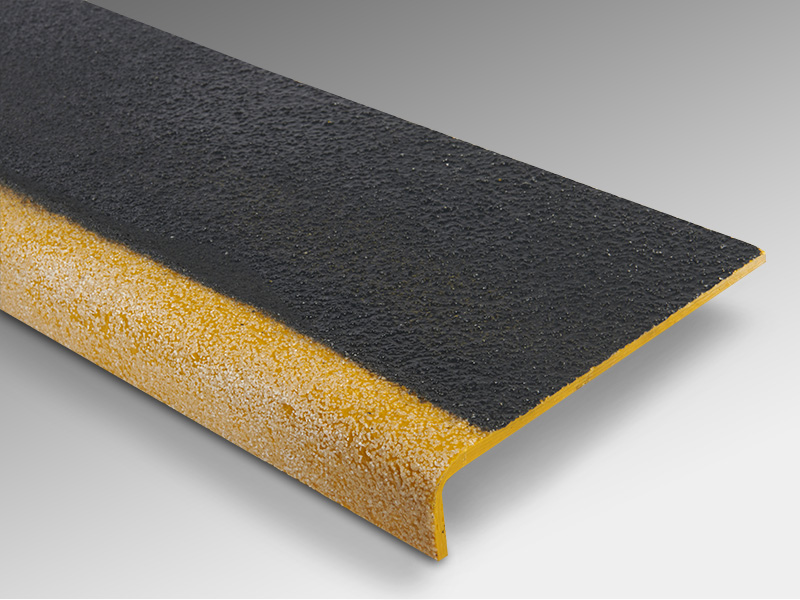

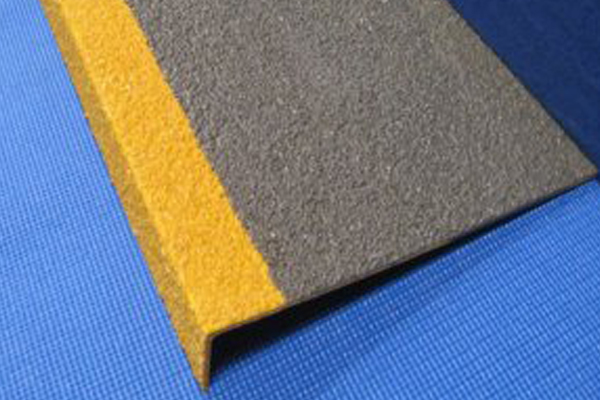

Covered Stair Treads:

- A solid top surface provides additional safety and a sleek aesthetic.

- Ideal for locations requiring enhanced cleanliness or spill prevention.

-

Heavy-Duty Stair Treads:

- Engineered to withstand high traffic and heavy loads.

- Used in industrial facilities and public spaces.

-

Custom Stair Treads:

- Tailored to specific applications, including unique dimensions, surface finishes, or color schemes.

6. Technical Specifications

- Espesor: Commonly available in thicknesses ranging from 25 mm (1 inch) to 50 mm (2 inches).

- Capacidad de carga: Can support heavy loads, often exceeding 500 kg/m² (100 lbs/ft²).

- Resistencia al deslizamiento: A high coefficient of friction (COF), typically exceeding 0.65, ensures excellent traction under wet and dry conditions.

- Resistencia al fuego: Conforms to standards like ASTM E84 for flame spread and smoke development.

- Temperature Tolerance: Operates effectively in temperatures ranging from -40°C to 120°C (-40°F to 248°F).

- Opciones de color: Standard colors include yellow, gray, and green, with custom colors available.

- Resistencia química: Resists acids, alkalis, and solvents commonly encountered in industrial settings.

7. Advantages of Pultruded FRP Stair Treads

-

Over Metal:

- Pultruded FRP is non-corrosive, eliminating the need for painting or coatings to prevent rust.

- Lightweight and easier to handle during installation.

-

Over Wood:

- Resistant to moisture, rot, and pests, making it ideal for outdoor use.

- Does not require frequent sealing or treatment.

-

Over Concrete:

- Lighter and easier to install without the need for heavy machinery.

- Not prone to cracking or spalling.

8. Installation Process

Pultruded FRP stair treads are designed for simple installation, making them accessible to professionals and DIY enthusiasts alike. The typical steps include:

- Preparación del sitio: Ensure the installation surface is clean, level, and free of debris.

- Measurement and Cutting: Treads are cut to the desired dimensions using standard tools with carbide or diamond-tipped blades.

- Positioning and Alignment: Place the treads on the staircase, aligning them for proper fit.

- Attachment: Secure the treads using adhesives, bolts, or specially designed mounting clips.

- Refinamiento: Apply edge seals or additional coatings if required.

9. Maintenance Guidelines

Pultruded FRP stair treads are designed to minimize maintenance efforts. However, periodic care is recommended to extend their lifespan:

- Clean with mild soap and water to remove dirt and debris.

- Inspect for signs of damage, such as cracks or loose fasteners.

- Avoid using abrasive cleaners that may degrade the surface grit.

- Reapply UV coatings or surface sealants as necessary in outdoor environments.

10. Certifications and Compliance

Pultruded FRP stair treads are manufactured to meet various international standards, ensuring safety and reliability in critical applications:

- OSHA (Occupational Safety and Health Administration): Ensures compliance with workplace safety regulations.

- ANSI (American National Standards Institute): Provides guidelines for slip resistance and structural integrity.

- ISO 9001: Guarantees quality management during production.

- ASTM Standards: Covers specifications for load-bearing capacity, fire resistance, and chemical resistance.

11. Environmental Benefits

Pultruded FRP stair treads are an environmentally responsible choice. Their extended lifespan reduces the need for replacements, lowering waste. Additionally, they require minimal maintenance, reducing the use of harsh cleaning chemicals and paints.

12. Frequently Asked Questions (FAQs)

-

What is the lifespan of pultruded FRP stair treads?

They can last 20-30 years or more, depending on the environment and level of maintenance. -

Are these treads suitable for outdoor use?

Yes, their UV resistance and corrosion-proof nature make them ideal for outdoor applications. -

Can the treads support heavy loads?

Absolutely, they are designed to handle industrial loads and comply with load-bearing standards. -

Are custom sizes available?

Yes, many manufacturers offer tailored solutions to fit specific requirements. -

Do they require special tools for installation?

No, standard tools like saws with diamond blades and basic fasteners are sufficient.

Conclusión

Pultruded FRP stair treads are a superior solution for enhancing safety, durability, and performance in a variety of applications. Whether for industrial plants, marine platforms, or residential staircases, these treads deliver unmatched reliability and versatility. Their combination of strength, lightweight construction, and resistance to environmental elements makes them a long-term investment that ensures safety and functionality in any setting.

Heavy-Duty Pultruded FRP Stair Treads - Industrial Grade

Serie :

Fiberglass Stair Treads >solicitud

Preguntas más frecuentes

Otros productos relacionados