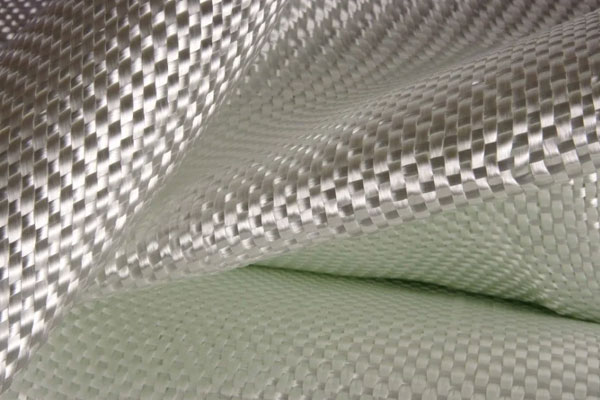

Glass Fiber Fabric (or Glass Fiber Cloth) is a highly versatile, woven fabric made from E-glass fibers (standard) or alkali-resistant (AR) glass fibers that are woven into a fabric structure. This fabric offers a wide range of thermal, electrical, and mechanical properties, making it ideal for composite reinforcement, insulation, y high-temperature applications.

Introducción al rendimiento del producto

Glass fiber fabric is widely used in composite manufacturing, including in applications such as aerospace, automotor, marine, industrial, construction, y electrical insulation. It is known for its excellent heat resistance, chemical stability, dimensional stability, y ligero nature, along with superior strength-to-weight ratio.

In terms of manufacturing, glass fiber fabrics can be plain woven, twill woven, o satin woven, depending on the required mechanical properties and the desired texture or appearance. The fabric may also be treated with various finishes (such as silane-based coupling agents) to improve resin compatibility and wetting, enabling its use in a range of composite and industrial applications.

🧪 Typical Technical Data (TDS Style)

| Parámetro | Typical Value / Range |

|---|---|

| Nombre del producto | Glass Fiber Fabric / Glass Fiber Cloth |

| Fiber Type | E-glass (alkali-free); optional AR-glass for corrosion resistance |

| Weave Type | Plain, Twill, Satin (customizable based on application) |

| Density / Weight | 100 – 800 gsm (customizable) |

| Espesor | 0.1 mm – 1.5 mm (depends on weight and weave type) |

| Resistencia a la tracción | 2000 – 4000 N/50 mm (depending on weave type and fiber type) |

| Moisture Content | ≤ 0.2% |

| Loss on Ignition (LOI) | 0.5% – 1.5% |

| Compatibilidad de resina | Polyester, Vinyl Ester, Epoxy, Phenolic |

| Ancho | 1000 mm, 1270 mm, 2000 mm (custom widths available) |

| Roll Length | 50 – 100 meters |

| Color | White / Off-white / Custom colors |

| Shelf Life | 12 months under proper storage conditions |

| Resistencia al fuego | Inherently fire-resistant (flame retardant) |

✅ Key Features and Benefits

-

Alta resistencia y durabilidad

Glass fiber fabric offers exceptional tensile strength y dimensional stability, making it suitable for high-performance composite applications. It retains its structural integrity even under mechanical stress or high temperatures, ensuring long-term reliability and durability. -

Excellent Thermal and Electrical Insulation

This fabric is highly resistant to high temperatures, withstanding heat up to 550°C (depending on resin system). It also provides excellent electrical insulation, making it ideal for electrical and electronic aplicaciones -

Resistencia química

Glass fiber fabric exhibits superior resistance to many harsh chemicals, including acids, alkalis, solvents, and oils. This makes it a preferred material for applications in corrosive environments or industries like chemical processing y marine applications. -

Lightweight yet Strong

Despite its strength, glass fiber fabric is extremely ligero, which is crucial in applications where reducing the overall weight of the component is important, such as in aerospace y automotor industrias. -

Flexibility and Molding Capability

The fabric can easily conform to complex mold geometries during manufacturing processes, such as hand lay-up, vacuum infusion, RTM, o spray-up, making it ideal for producing intricate composite parts. -

Versatile for Different Applications

Glass fiber fabric can be personalizado in terms of weave type (plain, twill, or satin), weight (gsm), and fiber type (E-glass or AR-glass), offering a wide range of options for different applications across industries. -

Moisture and UV Resistance

The fabric exhibits low moisture absorption, helping to maintain the integrity of composite materials in humid or wet environments. It also performs well when exposed to UV radiation, making it suitable for outdoor and marine environments.

🏭 Aplicaciones

Glass Fiber Fabric is used in a wide range of industries for various applications, including:

-

Aeroespacial: Lightweight structural components, composite fuselage panels, and insulation.

-

Automotor: Car body panels, bumpers, and other parts that require high strength-to-weight ratios.

-

Marina: Boat hulls, decks, and other marine components that need to withstand harsh conditions, including exposure to seawater.

-

Wind Energy: Reinforcement for wind turbine blades and other composite parts used in wind energy generation.

-

Construcción: Reinforced concrete, roofing materials, insulation, and fireproofing applications.

-

Electrical: Insulating cloth, protective wraps for cables, and electronic components.

-

Industrial: Pipes, ducts, tanks, and other industrial composite parts.

-

Equipo deportivo: Bicycles, skis, and other lightweight sporting goods.

📦 Packaging and Storage

-

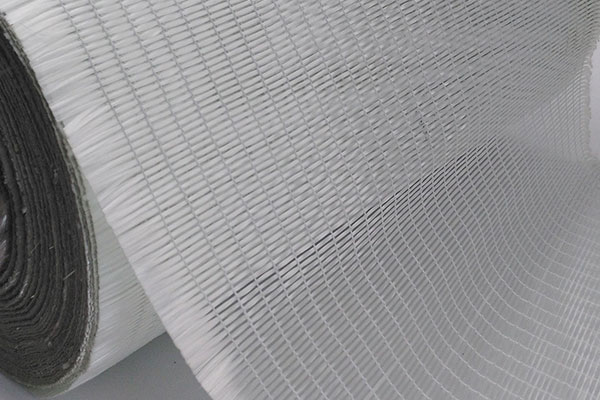

embalaje: Glass fiber fabric is typically packaged in rolls, with each roll wrapped in plastic film o kraft paper to protect it during transport and storage. The fabric is wound tightly to prevent damage during shipping.

-

Almacenamiento: Store in a dry, cool, and well-ventilated area, away from direct sunlight and moisture. Ensure that the material is not subjected to high humidity or extreme temperatures, which could degrade its properties.

-

Shelf Life: The shelf life of glass fiber fabric is typically 12 months when stored under proper conditions, though it may last longer if stored in ideal conditions.

🏅 Cumplimiento y certificaciones

-

ASTM D578 – Standard specification for glass fiber fabrics used in composite applications.

-

ISO 2559 / ISO 2797 – Standard testing methods for fiber weight, resin compatibility, and other physical properties.

-

RoHS Compliant – Ensures that the product is free from hazardous substances like lead, cadmium, and mercury.

-

ISO 9001 – Quality management system certification that ensures consistent product quality.

-

UL (Underwriters Laboratories) Certification – For flame retardancy and electrical insulation applications.

🛠 Opciones de personalización

-

Weave Types: Plain weave, twill weave, or satin weave. The choice of weave depends on the desired properties, such as strength, flexibility, y appearance.

-

Fiber Types: Available in E-glass for standard applications and AR-glass for corrosion-resistant environments.

-

Weight and Thickness: Customizable based on strength and flexibility requirements. Common ranges are from 100 gsm a 800 gsm.

-

Width and Length: Fabric width typically ranges from 1000 mm a 2000mm, with roll lengths of 50 meters to 100 meters, or customized to meet specific customer needs.

Glass Fiber Cloth

Serie :

Glass Fiber Fabric >solicitud

Preguntas más frecuentes

P:

What is the difference between glass fiber cloth and fiberglass tape?

A :

Glass Fiber Cloth: A woven fabric that comes in various sizes and thicknesses, commonly used for reinforcing composite parts, insulation, and thermal protection. Fiberglass Tape: A narrow width of fiberglass fabric, typically 10 mm to 100 mm wide, used primarily for wrapping, insulating, and reinforcing applications, especially around pipes, electrical components, and joints.

P:

Can glass fiber cloth be used in outdoor applications?

A :

Yes, glass fiber cloth can be used in outdoor applications. It is UV resistant and performs well in environments exposed to sunlight, which makes it ideal for marine and construction applications.

P:

How do I cut glass fiber cloth?

A :

To cut glass fiber cloth, it is best to use scissors or a rotary cutter. Ensure that you are wearing protective gloves and a mask, as cutting can generate small glass particles that could irritate your skin or lungs. Always cut in a well-ventilated area or use a dust extraction system.

P:

What resin is used with glass fiber cloth?

A :

Glass fiber cloth is compatible with a variety of resins, including: Epoxy resin: Provides strong bonding and excellent performance in high-strength applications. Polyester resin: Used for less demanding applications, offering a cost-effective solution for composite materials. Vinyl ester resin: Offers better resistance to corrosion and is used in applications where chemical resistance is critical.

Otros productos relacionados