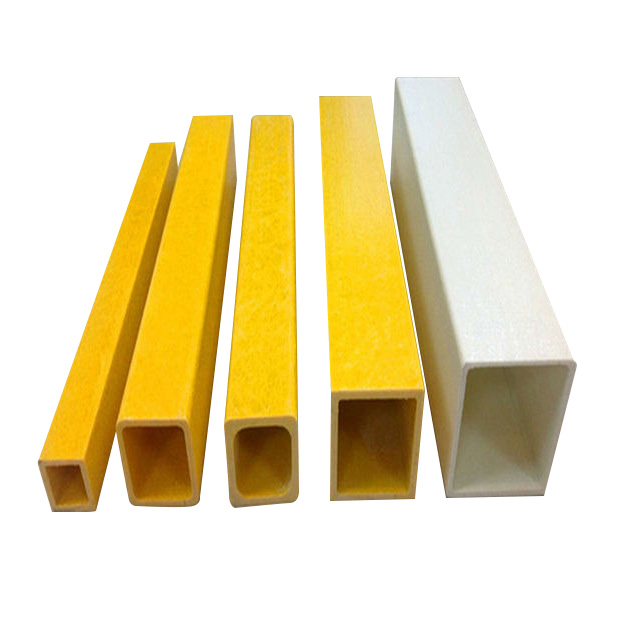

FRP (Fiber Reinforced Plastic) Special-Shaped Parts son custom-designed composite components made to meet specific structural, functional, or aesthetic requirements. Unlike standard FRP profiles, these parts are manufactured in complex shapes and geometries using molding, pultrusion, or filament winding techniques.

Introducción al rendimiento del producto

FRP structural angles are commonly used in construction, industrial applications, and infrastructure projects where traditional materials like steel or aluminum may not be suitable due to corrosion, weight, or maintenance concerns.

1. Physical Properties of FRP Structural Angle

FRP structural angles exhibit excellent mechanical, chemical, and thermal properties, making them an ideal alternative to traditional metal structures.

1.1. Strength & Durability

-

Alta relación resistencia-peso: FRP angles offer strength comparable to steel while being significantly lighter.

-

Flexural & Tensile Strength: They exhibit excellent resistance to bending and tensile forces, ensuring stability and structural integrity.

-

Impact Resistance: Unlike brittle materials, FRP can absorb impacts without cracking or deforming significantly.

1.2. Corrosion & Chemical Resistance

-

Resistant to Harsh Environments: Unlike steel, FRP does not rust, corrode, or degrade when exposed to moisture, chemicals, or UV radiation.

-

Chemical Stability: Suitable for chemical plants, wastewater treatment facilities, and marine applications where exposure to corrosive substances is common.

1.3. Electrical & Thermal Properties

-

No conductivo: FRP angles do not conduct electricity, making them safe for electrical and high-voltage applications.

-

Thermal Insulation: Unlike metals, FRP does not transfer heat easily, reducing the risk of burns and heat-related issues.

1.4. Fire Resistance

-

Fire-Retardant Options Available: Special resins such as phenolic or fire-retardant polyester can be used to meet fire safety requirements.

-

Low Smoke & Toxicity: Some FRP formulations produce minimal smoke and toxic fumes in case of fire.

2. Common Specifications & Sizes

FRP structural angles are available in various sizes, thicknesses, and configurations to suit different applications.

2.1. Standard Dimensions

-

Leg Lengths: Typically range from 25 mm × 25 mm (1” × 1”) a 150 mm × 150 mm (6” × 6”)

-

Espesor: Typically 3 mm (1/8”) to 12 mm (1/2”)

-

Lengths: Standard lengths are 3m (10ft), 6m (20ft), or custom lengths

2.2. Material Composition

-

Fibers: E-glass (most common), S-glass, carbon fiber (for specialized applications)

-

Resins: Polyester, Vinyl Ester (for high corrosion resistance), Epoxy (for superior mechanical properties), Phenolic (for fire resistance)

2.3. Mechanical Properties (Approximate Values)

| Propiedad | Typical Value |

|---|---|

| Resistencia a la tracción | 200-600 MPa |

| Resistencia a la flexión | 200-500 MPa |

| Resistencia a la compresión | 200-550 MPa |

| Densidad | 1.5-2.0 g/cm³ |

| Modulus of Elasticity | 20-35 GPa |

3. Advantages of FRP Structural Angle

FRP structural angles provide numerous benefits over traditional materials like steel, aluminum, or wood.

3.1. Lightweight Yet Strong

-

Up to 70% lighter than steel while maintaining high strength.

-

Easier to transport, handle, and install.

3.2. Corrosion & Weather Resistance

-

Ideal for marine, industrial, and outdoor environments where exposure to moisture, salt, and chemicals is common.

-

Eliminates the need for protective coatings and maintenance against rust.

3.3. Non-Conductive & Non-Magnetic

-

Safe for electrical installations y MRI rooms in medical facilities.

-

Used in power plants, substations, and telecom towers to prevent electrical hazards.

3.4. Low Maintenance & Long Service Life

-

Unlike steel, FRP does not require painting, galvanizing, or coating to maintain durability.

-

Resistant to biological degradation such as rot, mold, and insect damage.

-

Long lifespan of 20-50 years depending on application and environment.

3.5. Ease of Fabrication & Installation

-

Can be cut, drilled, and assembled using standard tools.

-

No welding required, making installation safer and easier.

-

Custom shapes and sizes can be manufactured as needed.

4. Disadvantages of FRP Structural Angle

Despite its many benefits, FRP structural angle has some limitations:

4.1. Higher Initial Cost

-

More expensive than traditional materials like steel or aluminum on a per-unit basis.

-

However, the lower maintenance costs y long lifespan can offset the initial investment.

4.2. Lower Stiffness Compared to Steel

-

Higher deflection under load, requiring additional reinforcement in some applications.

-

Not always suitable for high-load-bearing structures unless properly designed.

4.3. UV Degradation

-

Prolonged exposure to direct sunlight can cause surface degradation and color fading.

-

Requires UV-resistant coatings for long-term outdoor use.

4.4. Limited High-Temperature Performance

-

Standard FRP can soften at temperatures above 150-200°C.

-

Special high-temperature resins (such as phenolic) are required for fire-prone environments.

4.5. Difficult to Recycle

-

FRP materials are not easily recyclable compared to steel or aluminum.

-

Disposal options are limited, though some companies specialize in composite material recycling.

5. Applications of FRP Structural Angle

Due to its excellent properties, FRP structural angles are widely used in various industries.

5.1. Industrial Applications

-

Chemical Processing Plants: Supports and framing for equipment exposed to corrosive chemicals.

-

Tratamiento de agua y aguas residuales: Structural supports, walkways, and platforms resistant to moisture and chemicals.

5.2. Marine & Offshore

-

Dock & Pier Construction: Resistant to saltwater and does not corrode like steel.

-

Shipbuilding: Used in non-structural components requiring lightweight, corrosion-resistant materials.

5.3. Infrastructure & Construction

-

Bridges & Walkways: Used in pedestrian bridges and access structures in corrosive environments.

-

Railway & Roadside Applications: Non-conductive structures for railway signal supports and power substations.

5.4. Electrical & Telecommunication

-

Power Distribution: Used in high-voltage environments where metal structures would create hazards.

-

Telecom Towers: Supports and frames for antenna structures and communication panels.

6. Conclusion

FRP structural angles offer an excellent alternative to steel, aluminum, and wood in applications requiring corrosion resistance, lightweight strength, and electrical insulation. Their long lifespan, low maintenance, and ease of fabrication make them ideal for industrial, marine, infrastructure, and electrical applications.

However, higher initial costs, lower stiffness, and limited recycling options should be considered when choosing FRP over traditional materials. Proper design and material selection can maximize the benefits of FRP structural angles, making them a valuable solution for challenging environments.

FRP Structural Angle

Serie :

Productos principales >solicitud

Industrial Applications,Marine & Offshore,Infrastructure & Construction,Electrical & Telecommunication

Nombre de la marca :

TFcompuesto

Nombre del producto :

FRP Structural Angle

Material :

Fibra de vidrio

Color :

Gray,Other

Preguntas más frecuentes

P:

How long do FRP Special-Shaped Parts last?

A :

FRP Special-Shaped Parts have a service life of 25+ years, significantly outlasting many traditional materials such as wood (5-10 years) or steel (10-15 years, depending on conditions).

P:

Can FRP Special-Shaped Parts be used outdoors?

A :

Yes! FRP Special-Shaped Parts are highly UV-resistant and weatherproof, making them ideal for outdoor use in harsh environments like marine applications, chemical plants, and infrastructure.

P:

What are the typical dimensions and sizes of FRP Special-Shaped Parts?

A :

The dimensions of FRP Special-Shaped Parts vary greatly depending on the application and design. However, common sizes include: Length: Can be customized based on the project requirements (commonly 3m to 6m). Thickness: Typically 3mm to 50mm or more depending on strength needs. Width: Can be tailored based on the required shape and function (from small profiles to large sheets). Custom shapes such as curved, angled, and hollow profiles can be created to match exact design specifications.

Otros productos relacionados