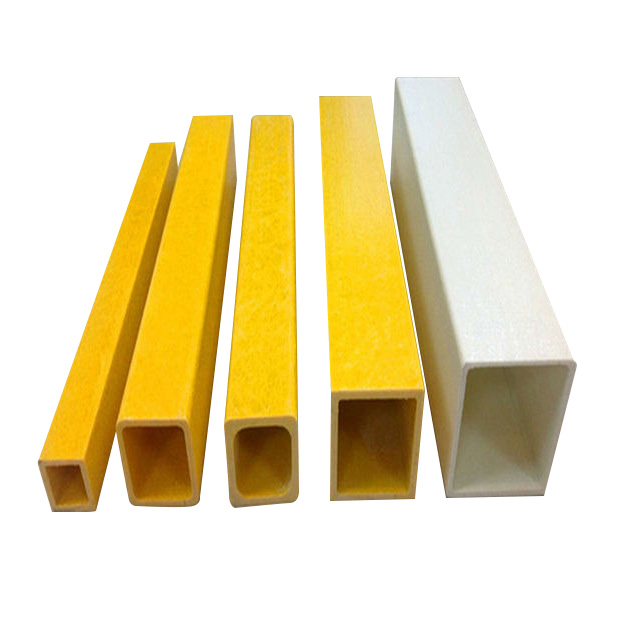

PRFV (Fiber Reinforced Plastic) U Channel is a structural profile made of high-strength fiberglass-reinforced polymer, designed for support, framing, and structural reinforcement. It is widely used in industrial, marine, chemical, and construction applications due to its corrosion resistance, lightweight, and high durability

Introducción al rendimiento del producto

What is an FRP U Channel?

Unlike traditional metal U channels (steel or aluminum), FRP U channels offer superior chemical resistance, electrical insulation, and minimal maintenance requirements.

2. Conventional Specifications & Dimensions

Common Specifications

| Especificación | Detalles |

|---|---|

| Material | Polímero reforzado con fibra de vidrio (FRP) |

| Tipos de resina | Polyester, Vinyl Ester, Epoxy |

| Shape | U-Channel |

| Opciones de color | Yellow, Gray, Green, Blue (Customizable) |

| Acabado de la superficie | Smooth, Gritted (Anti-Slip), UV-resistant coating |

| Opciones de retardantes de fuego | ASTM E84 Class 1 or 2 |

| Método de instalación | Bolted, Adhesive, Mechanical Fasteners |

Standard Dimensions

| Width (mm) | Height (mm) | Thickness (mm) | Length (m) |

|---|---|---|---|

| 25 | 25 | 3 | 6m / 12m |

| 40 | 40 | 4 | 6m / 12m |

| 50 | 50 | 5 | 6m / 12m |

| 75 | 75 | 6 | 6m / 12m |

| 100 | 100 | 6 | 6m / 12m |

| Custom sizes available upon request |

🔹 Custom Thickness, Lengths & Colors are available for specific project requirements.

🔹 Capacidad de carga depends on fiber orientation, resin type, and thickness.

3. Key Advantages of FRP U Channel

✅ Corrosion & Chemical Resistance

-

FRP U channels are immune to rust, oxidation, and chemical degradation.

-

Ideal for marine, offshore, and chemical environments where steel fails.

✅ Lightweight Yet Strong

-

Up to 70% lighter than steel, making handling and installation easier.

-

Maintains high strength-to-weight ratio, suitable for structural support.

✅ Aislamiento eléctrico y térmico

-

Non-conductive, ensuring safe use near electrical equipment.

-

Low thermal conductivity, reducing heat transfer in extreme environments.

✅ Low Maintenance & Long Service Life

-

Does not require painting or coating like metal U channels.

-

Lifespan of 25+ years, reducing long-term replacement costs.

✅ Fire Retardant Options Available

-

Available in ASTM E84 Class 1 or Class 2 fire-retardant versions.

-

Suitable for applications requiring fire safety compliance.

✅ Easy Fabrication & Installation

-

Can be cut, drilled, and installed using simple tools.

-

No need for welding, reducing labor costs and complexity.

4. Applications of FRP U Channel

FRP U channels are widely used across multiple industries due to their versatility, durability, and corrosion resistance.

🔹 Industrial & Structural Applications

✔ Structural framing for factories, warehouses, and bridges.

✔ Support structures in electrical substations.

✔ Framing components in construction and civil engineering projects.

🔹 Marine & Offshore Industry

✔ Used in shipbuilding, offshore platforms, and harbors.

✔ Ideal for dock supports and marine walkways.

🔹 Chemical & Petrochemical Plants

✔ Resistant to acids, alkalis, and corrosive gases.

✔ Used in chemical processing plants, wastewater treatment, and storage facilities.

🔹 Electrical & Power Infrastructure

✔ Non-conductive, making it ideal for power stations and transmission towers.

✔ Used for cable tray supports and electrical enclosure frames.

🔹 Water & Wastewater Treatment Facilities

✔ Corrosion-resistant support structures for water tanks, treatment plants, and desalination units.

🔹 Transportation & Infrastructure

✔ Used in railway platforms, pedestrian bridges, and highway structures.

✔ Supports fiber optic cable systems and telecom towers.

5. Comparison: FRP U Channel vs. Steel & Aluminum U Channels

| Característica | FRP U Channel | Steel U Channel | Aluminum U Channel |

|---|---|---|---|

| Peso | Ligero | Heavy | Moderado |

| Resistencia a la corrosión | Excelente | Poor (Rusts) | Bien |

| Maintenance | Bajo | High (Needs Coating) | Moderado |

| Conductividad eléctrica | No conductivo | Conductive | Conductive |

| Installation Complexity | Easy | Requires Welding | Moderado |

| Lifespan | 25+ years | 10-15 years (with maintenance) | 15-20 years |

6. FRP U Channel Installation Methods

Installing FRP U channels is straightforward and requires no special welding or heavy equipment.

🔩 Installation Techniques

-

Bolted Assembly – Stainless steel or FRP fasteners for strong connections.

-

Adhesive Bonding – High-strength structural adhesives for seamless installation.

-

Mechanical Fasteners – Suitable for modular construction applications.

🛠 Tools Required

-

Standard Power Tools – Can be cut and drilled using common tools.

-

No Special Welding – Unlike steel, no welding is required, reducing labor costs.

7. How to Choose the Right FRP U Channel?

Consider the following factors when selecting an FRP U Channel:

✅ Capacidad de carga – Choose the correct thickness and width for your application.

✅ Resin Type – Poliéster (standard), Éster de vinilo (chemical-resistant), or Epoxy (high-strength).

✅ Protección UV – For outdoor applications, UV-resistant coatings are recommended.

✅ Fire Retardant Requirement – Select fire-retardant FRP if needed.

8. Frequently Asked Questions (FAQ)

Q1: How strong is an FRP U Channel compared to steel?

FRP U channels have a high strength-to-weight ratio, making them strong enough for most structural applications while being significantly lighter than steel.

Q2: Are FRP U Channels fire-resistant?

Yes! Fire-retardant options are available that meet ASTM E84 Class 1 or Class 2 standards.

Q3: Can FRP U Channels be used outdoors?

Absolutely! They are weatherproof, UV-resistant, and corrosion-resistant, making them ideal for outdoor and marine applications.

Q4: How long does an FRP U Channel last?

FRP U channels have a lifespan of 25+ years, compared to steel (10-15 years) in corrosive environments.

Q5: Can FRP U Channels be customized?

Yes! Custom sizes, colors, pre-drilled holes, and reinforced coatings are available upon request.

9. Conclusion

FRP U channels offer an excellent alternative to steel and aluminum, with superior corrosion resistance, lightweight properties, and a long service life. They are widely used in industrial, marine, chemical, and construction applications where traditional materials fail due to corrosion and weight concerns.

FRP U Channel

Serie :

Productos principales >solicitud

🔹 Industrial Structures – Support frames, walkways, and platforms. 🔹 Marine & Offshore – Shipbuilding, docks, and oil rigs. 🔹 Chemical & Petrochemical – Acid-resistant structural components. 🔹 Electrical & Power – Non-conductive framing and cable support. 🔹 Water & Wastewater – Corrosion-resistant water treatment structures.

Nombre de la marca :

TFcompuesto

Nombre del producto :

FRP U Channel

Material :

Fibra de vidrio

Color :

Yellow,Gray,Other

Preguntas más frecuentes

P:

What resin types are available for FRP U Channels?

A :

FRP U Channels can be made using different resin types for various applications: Polyester Resin – Standard use, cost-effective, good corrosion resistance. Vinyl Ester Resin – Superior chemical resistance, ideal for harsh environments. Epoxy Resin – High strength, excellent structural integrity.

P:

Are FRP U Channels fire-resistant?

A :

Yes! Fire-retardant FRP U Channels are available and can meet ASTM E84 Class 1 or Class 2 fire safety standards.

P:

Can FRP U Channels be used outdoors?

A :

Absolutely! FRP U Channels are: ✅ UV-resistant (optional UV protective coating available). ✅ Weatherproof, withstanding extreme temperatures and humidity. ✅ Corrosion-resistant, ideal for marine, industrial, and chemical plants.

P:

How strong is an FRP U Channel compared to steel?

A :

While FRP is lighter than steel, it has a high strength-to-weight ratio, making it suitable for structural applications. It performs exceptionally well in corrosive environments, where steel would degrade over time.

Otros productos relacionados