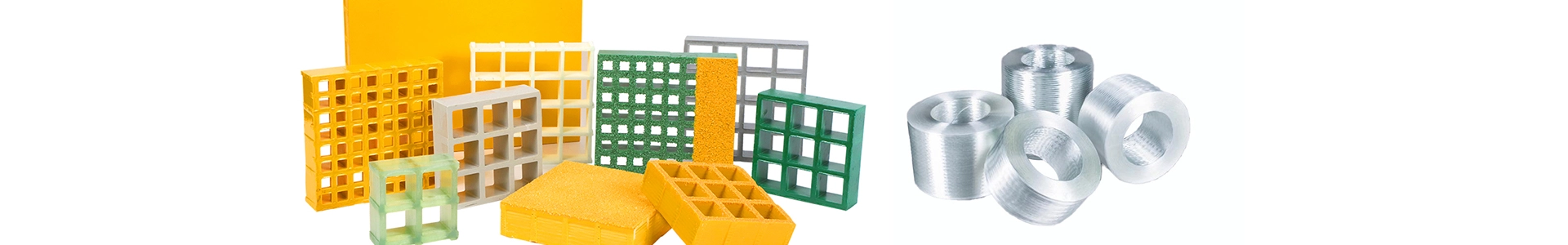

- Fiberglass Molded Grating ( 37 )

- Fiberglass Pultruded Grating ( 6 )

- Fiberglass Handrail System ( 6 )

- Fiberglass Cover Plate ( 7 )

- Fiberglass Pultruded Profiles ( 20 )

- Plastic Grating ( 9 )

Product Categories

-

FRP Molded Grating 38MM Yellow

Product Description FRP Grating (Fiberglass Reinforced Plastic Grating) is a structural grid made from fiberglass-reinforced plastic composite. It's designed for use in applications that r...

-

FRP Molded Grating Blue Concave Surface 50mm

Product Description FRP Grating (Fiberglass Reinforced Plastic Grating) is a structural grid made from fiberglass-reinforced plastic composite. It's designed for use in applications that r...

-

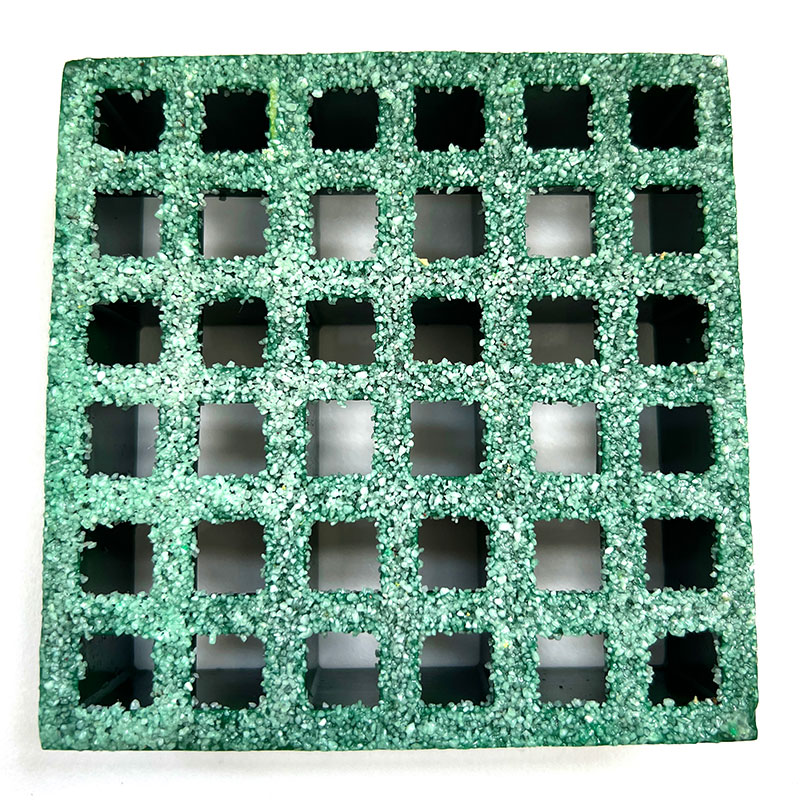

FRP Molded Grating Green Micro Mesh 20mm

Product Description FRP Grating (Fiberglass Reinforced Plastic Grating) is a structural grid made from fiberglass-reinforced plastic composite. It's designed for use in applications that r...

-

Detailed Overview of FRP Handrail Systems

The GRP external Swivel is a versatile in-line swivel fitting, often used where angles vary on slops, steps and landings. The GRP 116 Mid Corner is a 90° corner joint, often used...

-

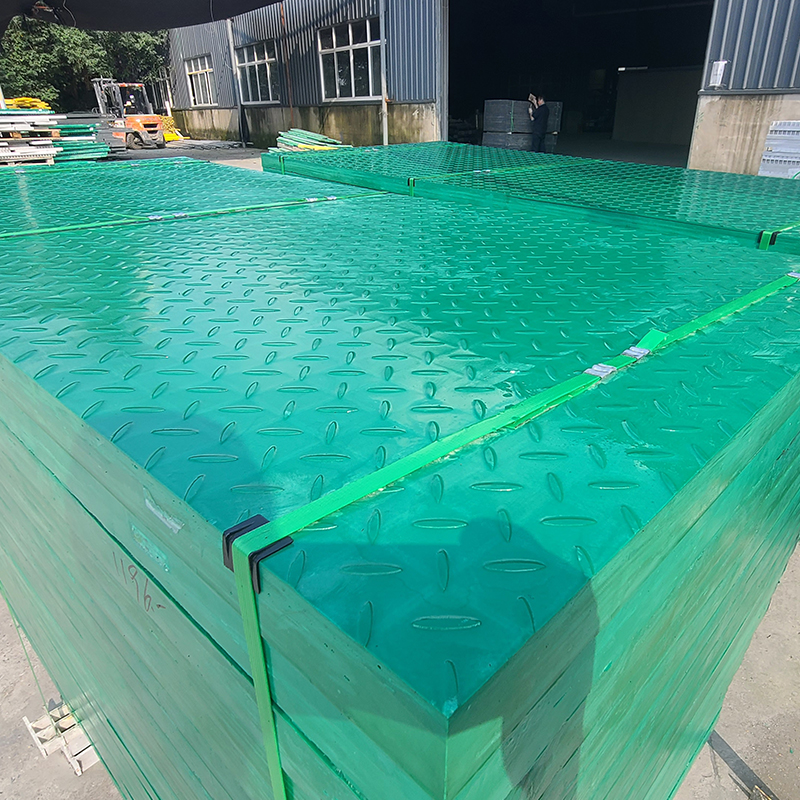

FRP cover plate for chemical plant applications

The Fiberglass Cover Plate is a high-performance solution crafted from fiberglass reinforced plastic (FRP), designed to offer a lightweight, strong, and corrosion-resistant alternative to tradition...

-

FRP cover plate fiberglass trench cover

The Fiberglass Cover Plate is a high-performance solution crafted from fiberglass reinforced plastic (FRP), designed to offer a lightweight, strong, and corrosion-resistant alternative to tradition...

-

FRP cover plate fiberglass trench cover corrosion-resistant lightweight

The Fiberglass Cover Plate is a high-performance solution crafted from fiberglass reinforced plastic (FRP), designed to offer a lightweight, strong, and corrosion-resistant alternative to tradition...

-

fiberglass walkway covers heavy-duty FRP trench anti-slip high-strength

The Fiberglass Cover Plate is a high-strength, corrosion-resistant solution designed to cover trenches, flooring, walkways, and other areas where durability and safety are crucial. Made from high-q...

-

Fiberglass FRP Cover Plate walkway chemical-resistant trench low-maintenance

The Fiberglass Cover Plate is a high-strength, corrosion-resistant solution designed to cover trenches, flooring, walkways, and other areas where durability and safety are crucial. Made from high-q...

-

GRP handrail system fiberglass corrosion-resistant non-slip eco-friendly

The GRP external Swivel is a versatile in-line swivel fitting, often used where angles vary on slops, steps and landings. The GRP 116 Mid Corner is a 90° corner joint, often used...

-

industrial GRP non-slip safety fiberglass lightweight corrosion-resistant UV-resistant fire-resistant handrails

The GRP external Swivel is a versatile in-line swivel fitting, often used where angles vary on slops, steps and landings. The GRP 116 Mid Corner is a 90° corner joint, often used...

-

GRP handrail

The GRP external Swivel is a versatile in-line swivel fitting, often used where angles vary on slops, steps and landings. The GRP 116 Mid Corner is a 90° corner joint, often used...