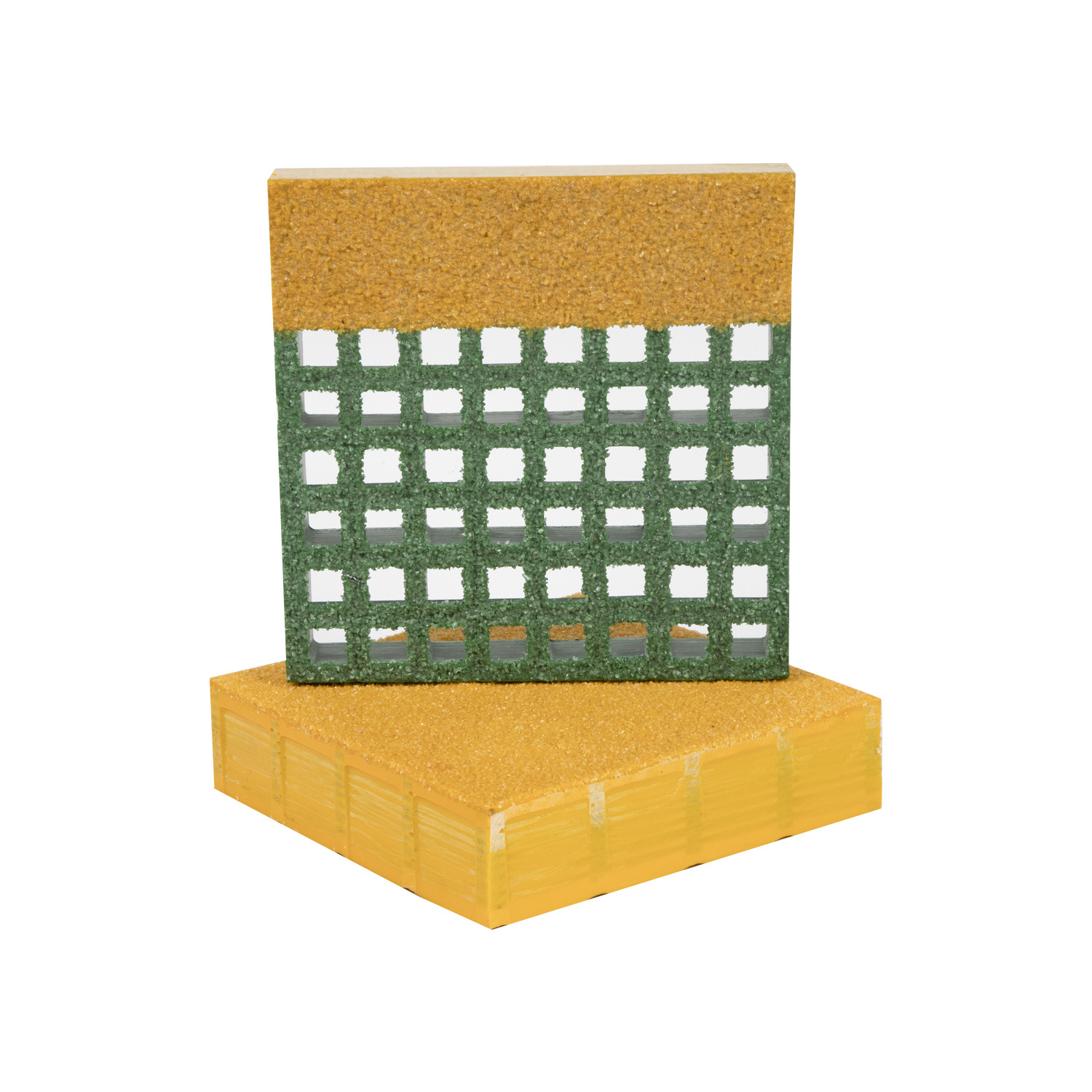

Fiberglass reinforced plastic grating (also known as FRP grating, glass reinforced plastic grating or fiberglass grating) is a composite material manufactured by combining a matrix of resin and fiberglass. FRP grating is a structural product that can be weight-bearing between spans.

Product performance introduction

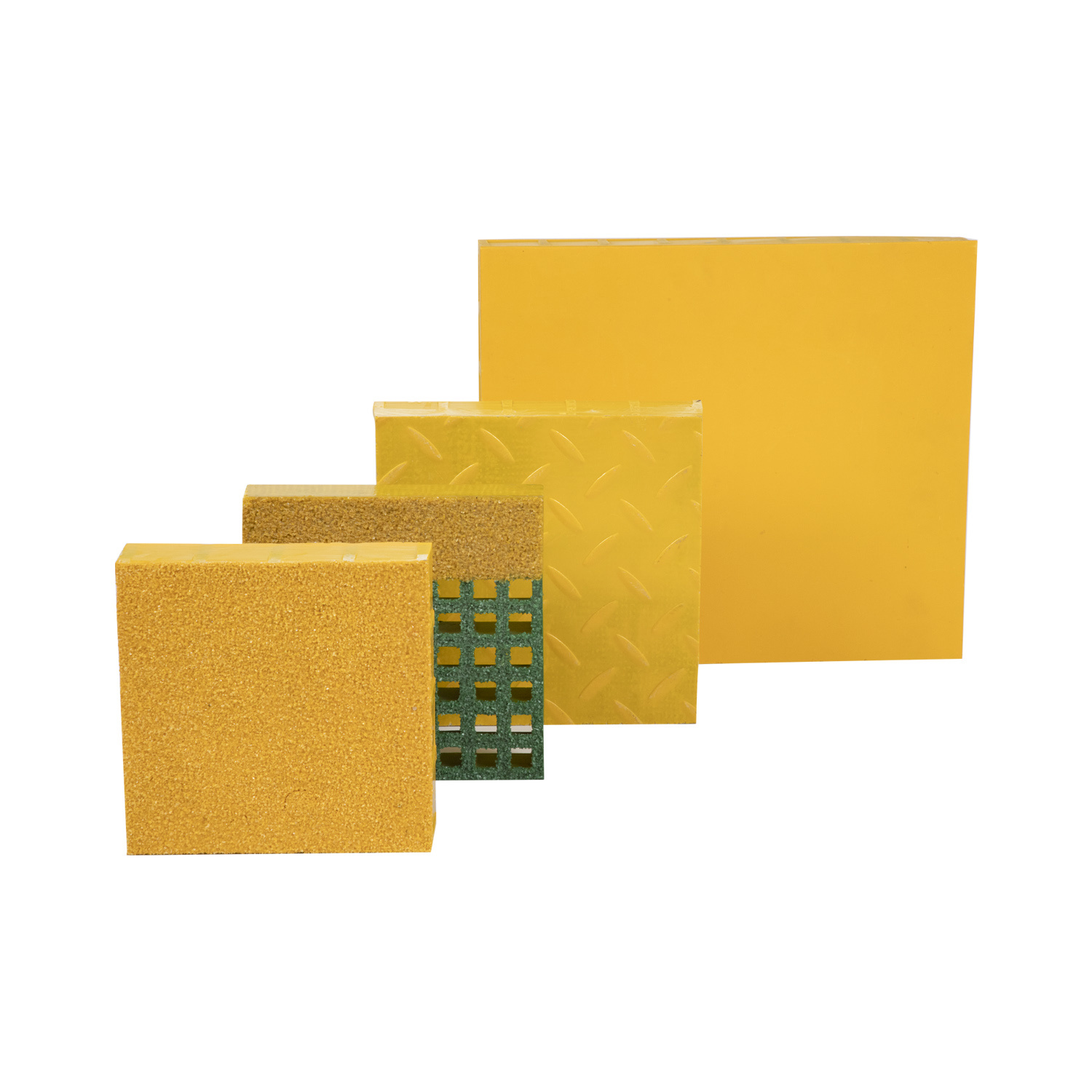

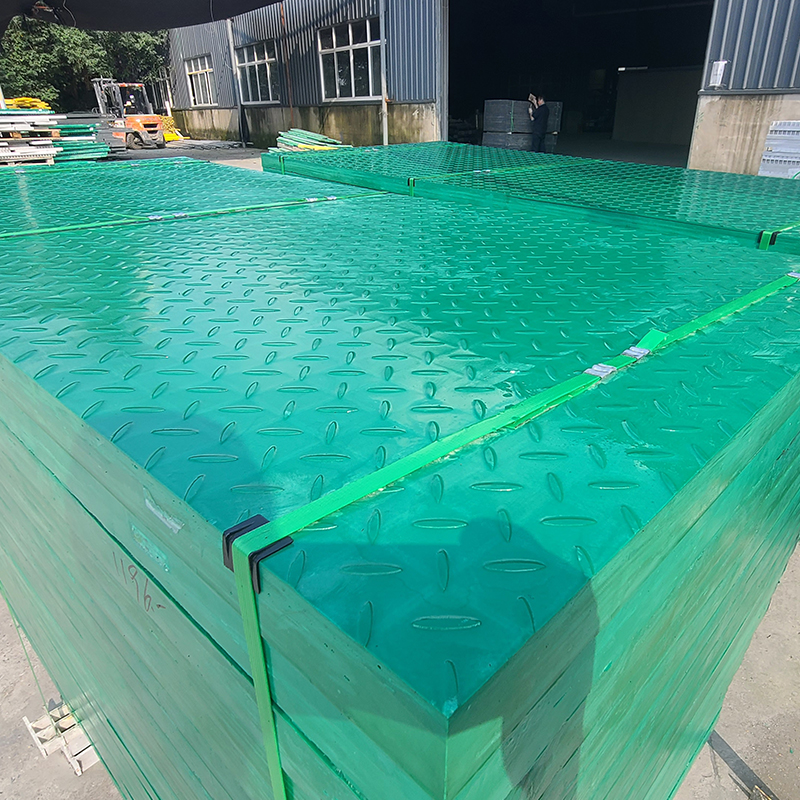

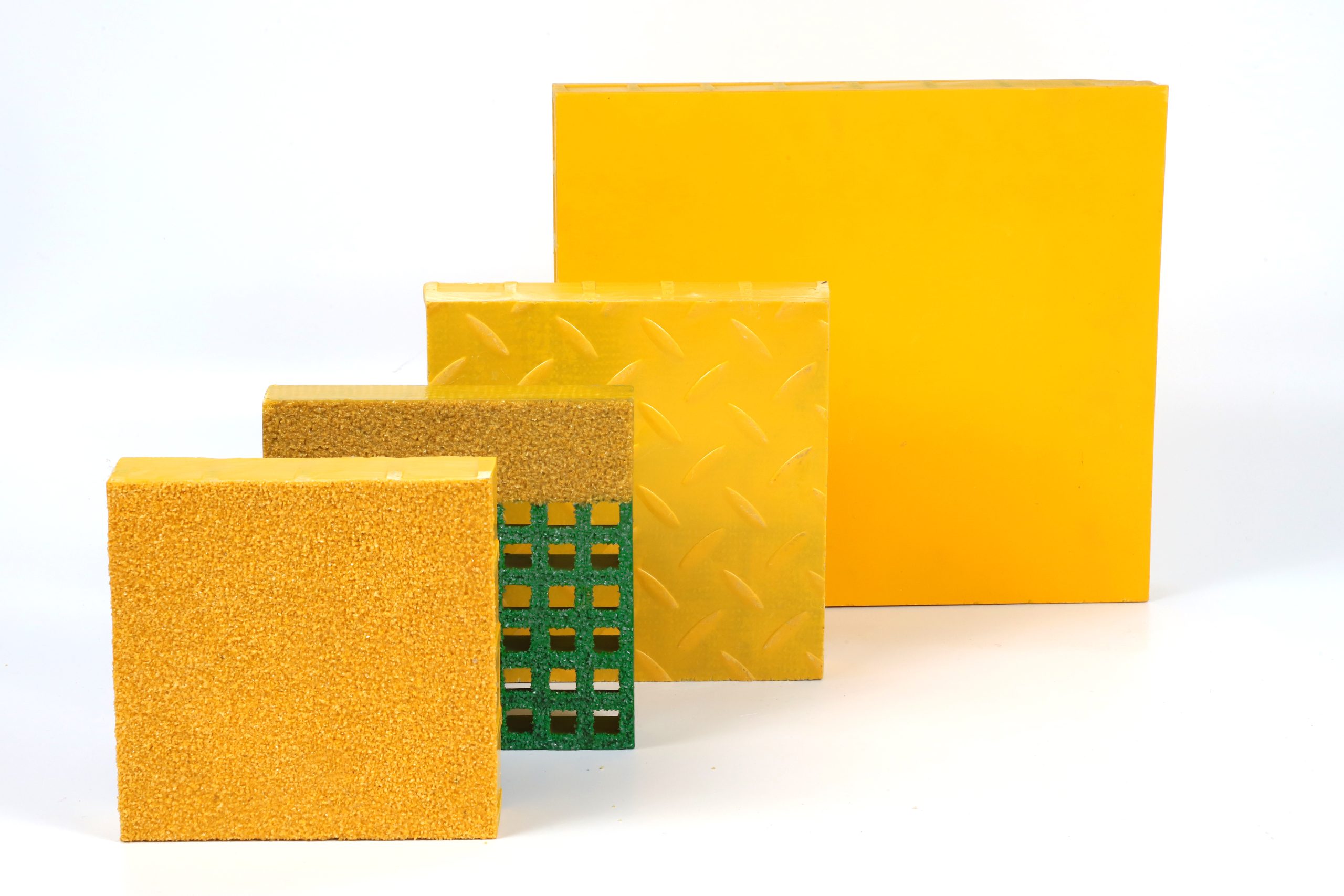

The Fiberglass Cover Plate is a high-strength, corrosion-resistant solution designed to cover trenches, flooring, walkways, and other areas where durability and safety are crucial. Made from high-quality fiberglass reinforced plastic (FRP), it offers an excellent alternative to traditional metal or concrete covers, being lightweight, non-corrosive, and maintenance-free. These cover plates are suitable for various environments, including industrial facilities, marine applications, and wastewater plants.

Key Features:

- Material: Fiberglass Reinforced Plastic (FRP)

- Corrosion Resistance: Excellent for use in harsh environments, including chemical and saltwater exposure

- Lightweight: Easier to handle and install compared to metal or concrete alternatives

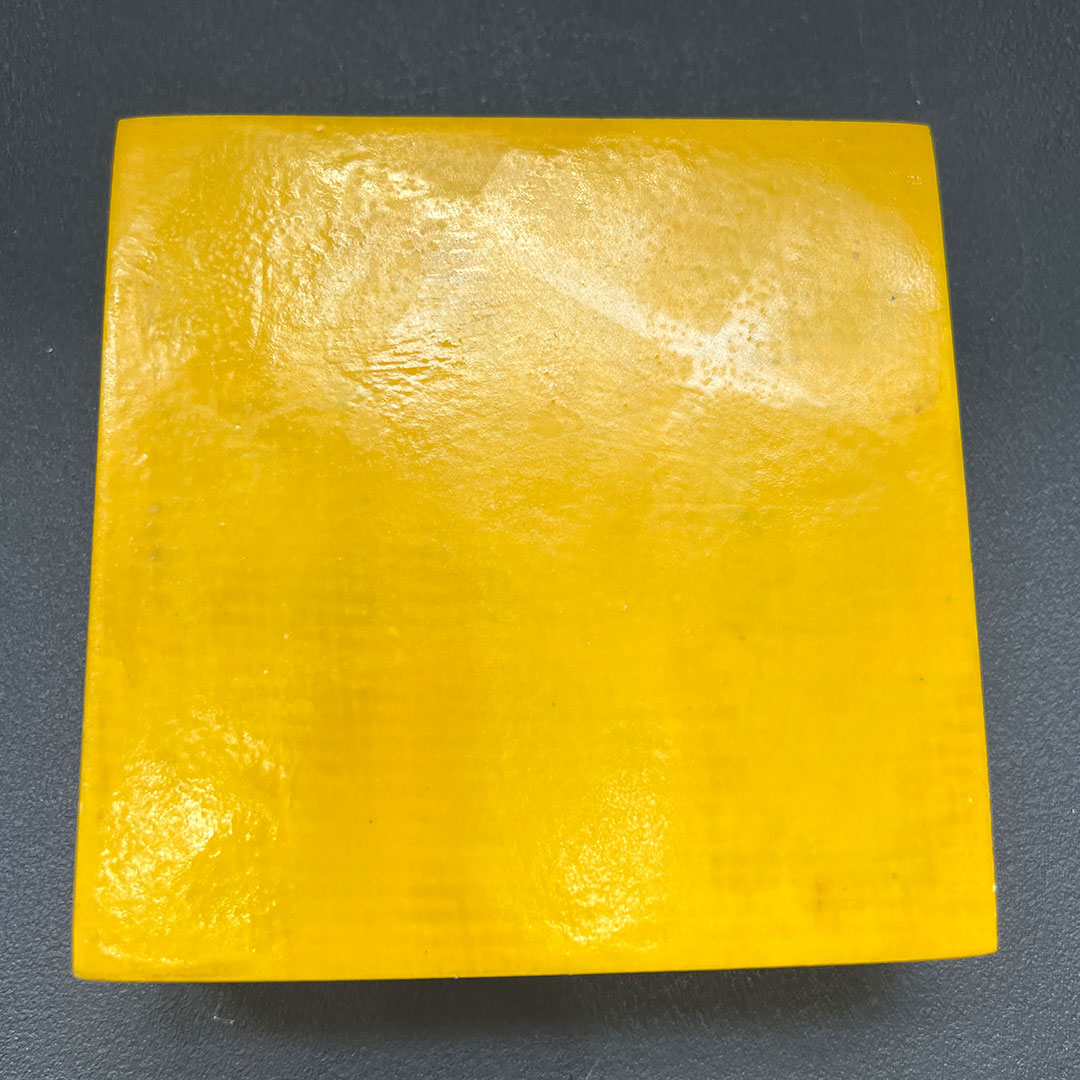

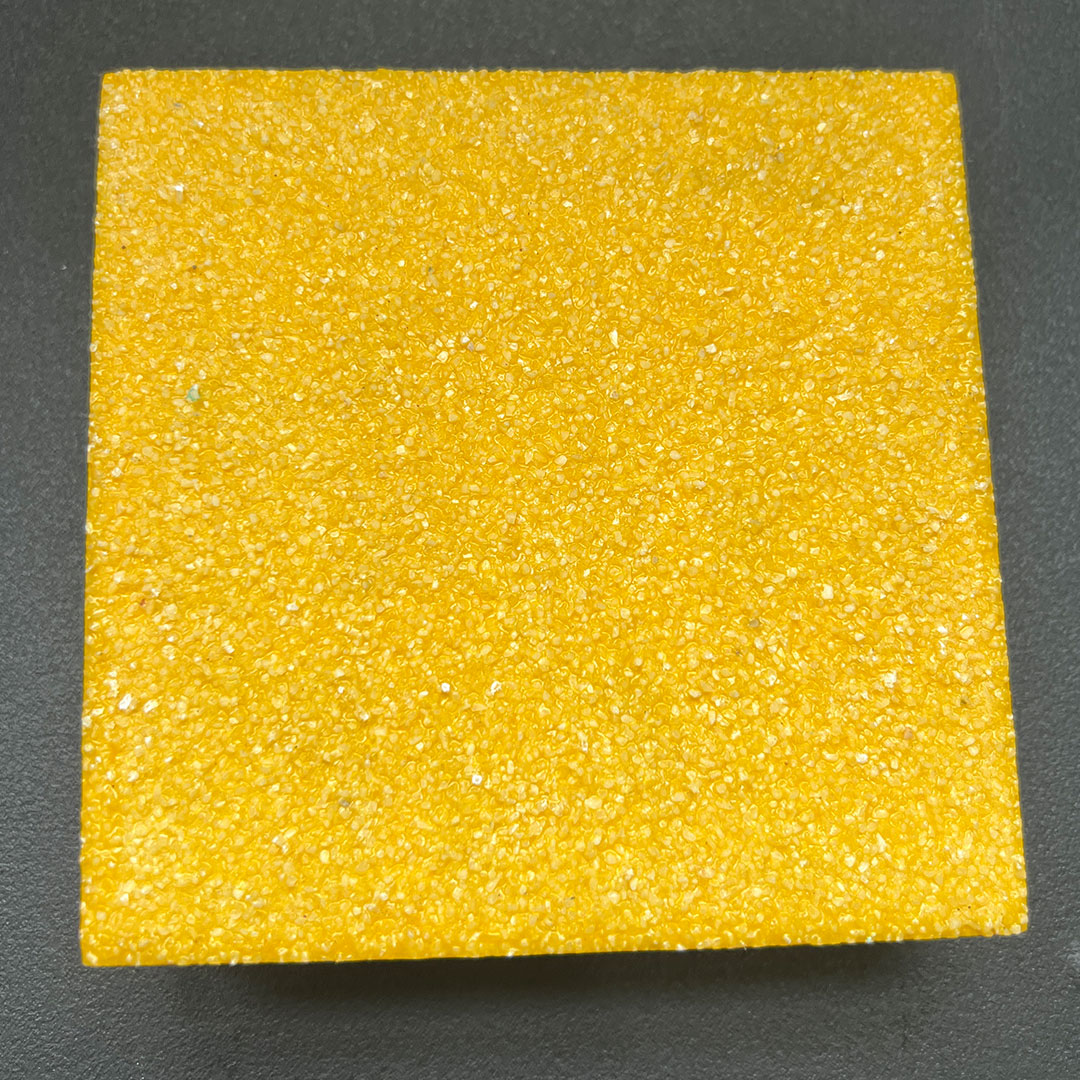

- Anti-Slip Surface: Textured top surface to reduce slip risks

- Fire Retardant: Available with fire-resistant resins to meet safety standards

- UV Protection: UV-resistant properties, ideal for indoor and outdoor use

- Customizable: Available in different thicknesses, colors, and load ratings

- Impact Resistant: Durable and capable of withstanding heavy loads and impacts

Fiberglass cover plate

Applications:

- Industrial Facilities: Covering trenches, cable ducts, and chemical processing areas

- Marine & Coastal: Suitable for docks, marinas, and ports where corrosion resistance is needed

- Water & Wastewater Treatment: Resists corrosion from water, chemicals, and damp environments

- Commercial Areas: Use in walkways, stairwells, and platforms in malls and commercial buildings

- Transportation: Ideal for covering tracks, conduits, and cables in transit stations and depots

Specifications:

- Thickness Options: Typically 5–50 mm, customizable based on application and load requirements

- Width & Length: Standard and custom dimensions available to fit various trenches and walkways

- Load Rating: Designed to support pedestrian and vehicular loads according to specific needs

- Color Options: Standard colors include gray, yellow, green, and custom colors for branding

- Surface Texture: Anti-slip grit surface, patterned or smooth finish options available

Benefits:

- Durability: High resistance to chemicals, salt, and UV exposure, ensuring long service life

- Lightweight: Easier to install, move, and handle compared to metal or concrete covers

- Safety: Anti-slip surface minimizes accident risks; fire-retardant options meet safety standards

- Aesthetic Flexibility: Available in various colors, enhancing visibility or matching site aesthetics

- Low Maintenance: Requires minimal upkeep compared to metal and wood; no need for painting or sealing

Installation:

- Ease of Installation: Lightweight design allows for easy handling and installation, reducing labor costs

- Mounting Options: Can be bolted down or secured with clamps based on the application’s load and safety requirements

- Custom Fit: Manufactured to specified dimensions for a snug fit over trenches or walkways

Maintenance:

- Cleaning: Routine cleaning with mild soap and water to remove dirt and debris

- Inspection: Regular inspection advised to check for damage or wear in high-traffic areas

- Low Maintenance: No rust, peeling, or chipping, providing long-term performance with minimal upkeep

Warranty:

- Standard Warranty: 5-10 years warranty against manufacturing defects, subject to proper use

- Extended Warranty: Options available for extended coverage based on application needs

Compliance:

- Standards: Complies with OSHA and other industry safety standards

- Fire Rating: Meets or exceeds Class 1 and Class 2 fire rating standards where required

- Anti-Slip Certification: Certified slip-resistant surfaces available for areas with strict safety requirements

Fiberglass FRP Cover Plate walkway chemical-resistant trench low-maintenance

Series :

Main Products >application

Chemical industry, paper industry, power plant, sewage treatment plant, offshore drilling platform, food processing plants melting.Refineries, mines, salt farms, nuclear power plants.battery plants and so on. Can be used as: pedestrian walkway, bridge plank, work lndustrial floor, operating platform, trench cover, pallet, guardrail, fence, shelf, isolation belt, green walkway, Floor step,etc.

Brand name :

TFcomposite

Product name :

Fiberglass Cover Plate

Technique :

Molded

Material :

Unsaturated polyester resin and glass fiber roving

MOQ :

50pcs

FAQ

Q :

Are you a factory that produces FRP molded grating?

A :

Yes, we are a professional manufacturer of FRP gratings, we have covers an area of nearly 15,000 square meters, has nearly 120 employees, equipped more than 100 sets of standard grating molds, 15 automatic pultrusion lines.

Q :

How to choose if there is a requirement for the load bearing of the FRP grating?

A :

It depends on the application where you buy the grating, whether it is a walkway or a passing vehicle.

Q :

We are a decoration company, can we buy your FRP grating as decorations?

A :

Yes, our colors can be customized according to customer needs, we can make all the colors on the Raul color card.

Q :

Do you guarantee after-sales service when purchasing your FRP grating?

A :

Yes, we can guarantee two years of after-sales.

Other related products