Fiberglass products for compression molding

We are a reputable supplier of glass fiber raw materials including direct roving, chopped strands, mat, and yarn. We maintain ample stock and offer competitive prices. Feel free to reach out to us through our online inquiry form, accessible 24/7.

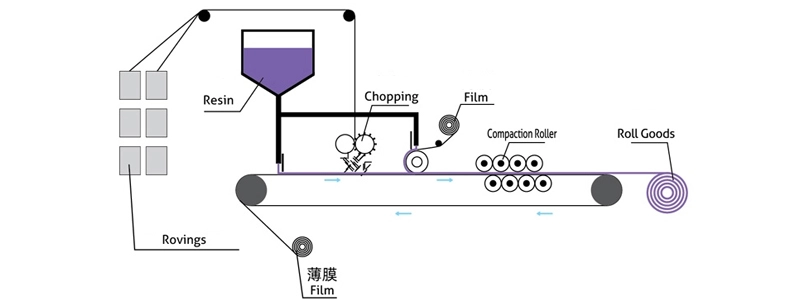

SMC Process

Mix the resins,fillers and other materials well to form a resin paste, apply the paste on a first film,disperse chopped glass fibers evenly on the resin paste film and cover this paste film with another layer of resin paste film,and then compact the two paste films with pressure rollers of a SMC machine unit to form sheet molding compound products.

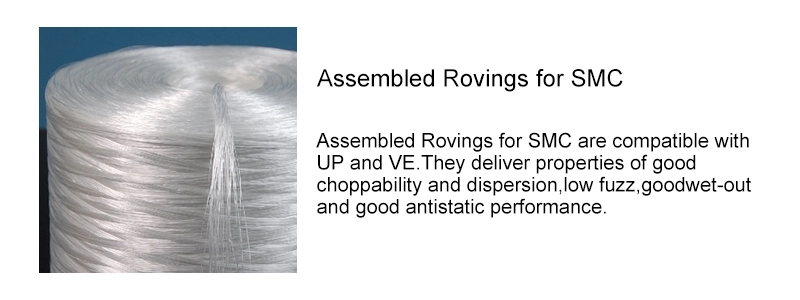

Assembled Rovings for SMC

Assembled Rovings for SMC are compatible with UP and VE.They deliver properties of good choppability and dispersion,low fuzz,goodwet-out and good antistatic performance.

-

Product CodeProduct FeaturesTypical ApplicationData Download

-

SMC sanitary products with high boiling resistance

Unit bathroom

-

SMC sanitary products with high boiling resistance

Unit bathroom

-

Car ceiling

Car ceiling

-

SMC products with high surface quality and easy coloring

Waterproof board, water tank, electrical cabinet, etc

-

SMC structural parts with high strength and high glass fiber content

Automobile structural parts

-

SMC products with Grade-A surface

Automobile exterior parts

-

SMC products with high surface quality and easy coloring

Bathroom wares

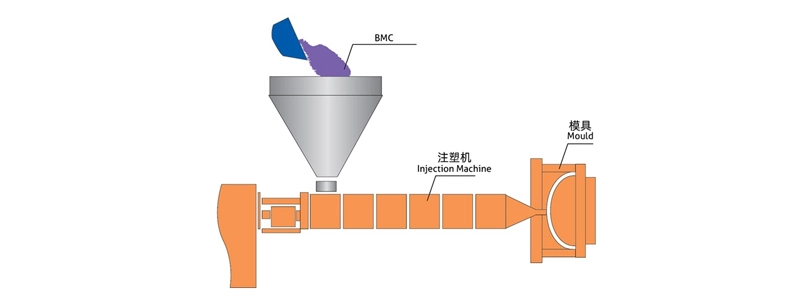

BMC Process

A bulk molding compound is made by combining glasschoppedstrands,resin,filler,catalystand other additives.This compound is processed by compression molding or injection molding to form the finished composite parts.

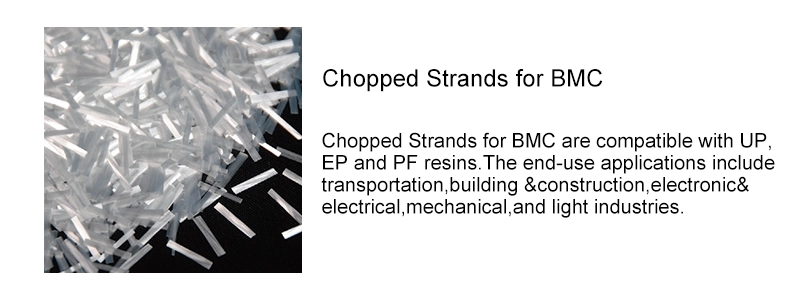

Chopped Strands for BMC

Chopped Strands for BMC are compatible with UP,EP and PF resins.The end-use applications include transportation,building &construction,electronic&electrical,mechanical,and light industries.

-

Product CodeProduct FeaturesTypical ApplicationData Download

-

High impact strength, high LOI rate

Automotive parts, civilian electrical switches, electric tools, artificial marble platform boards and other products requiring high strength

-

Suitable for the dry mixing processing, high strand integrity High strand stiffness, compatible with rubber

Friction materials, Products with superior friction coefficiency, including tires

-

Extremely low resin demand, delivering low viscosity to BMC paste

High fiberglass content products with complex structure and superior color, e.g., ceiling, artificial marble platform boards and lampshades

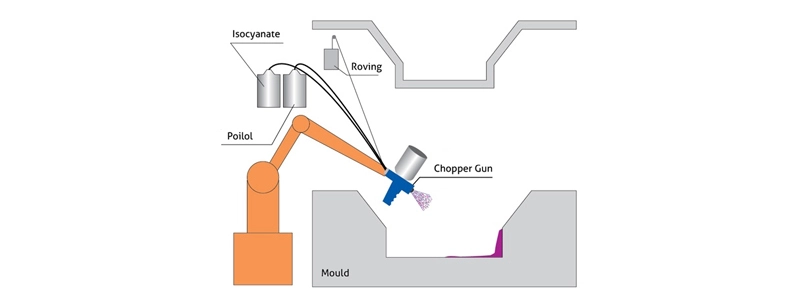

LFI Process

The roving is chopped into certain length using a spraying machine. The isocyanate, polyol, and chopped strand mixture is sprayed onto an open mould.The mould is then closed, heated and pressure applied, and the part is cured.

Assembled Rovings for LFI

Assembled Rovings for LFl are compatible with PU and VE.They deliver properties of lowstatic,excellent dispersion and good wet-out in resin.