Fiberglass products for fabrics & mats

We are a reputable supplier of glass fiber raw materials including direct roving, chopped strands, mat, and yarn. We maintain ample stock and offer competitive prices. Feel free to reach out to us through our online inquiry form, accessible 24/7.

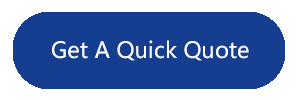

Weaving Process

Woven fabrics are made on looms with warp or weft reinforcement threads interlaced with each other in varying configurations to give different fabric styles.

Direct Rovings for Weaving

Direct Rovings for Weaving are compatible with polyester, vinyl ester and epoxy resins. Their excellent weaving properties make them suitable for use in various products, such as wind blades, mesh fabrics, geotextiles, lightweight fabrics and woven roving.

-

Product CodeProduct FeaturesTypical ApplicationData Download

-

Compatible with multiple resin systems, excellent mechanical properties of composite products

UD or multiaxial fabrics used in large wind blades by vacuum infusion and prepreg processes

-

Compatible with epoxy resin, fast wet out, excellent mechanical properties of composite products, with high tensile strengh and good fatigue resistance

UD or multiaxial fabrics used in large wind blades by vacuum infusion process

-

Compatible with epoxy resin, fast wet out, excellent mechanical properties of composite products, with high tensile strengh and good fatigue resistance

UD or multiaxial fabrics used in large wind blades by vacuum infusion process

-

Low fuzz, excellent weaving property, excellent mechanical properties of composite products

UD fabrics used in large polyester wind blades by vacuum infusion process

-

Low fuzz, good compatibility with resin, and high mechanical properties

Woven roving, used in pipes and boats

-

Low fuzz, good compatibility with resin, and high mechanical properties

Woven roving, used in pipes and boats

-

Excellent weaving property, excellent mechanical properties of composite products

Multiaxial fabrics used in large wind blades by prepreg process

-

Compatible with epoxy resin, excellent weaving property, excellent mechanical properties of composite products

UD or multiaxial fabrics used in large wind blades by vacuum infusion process

Roving for Geotextiles

-

Product CodeProduct FeaturesTypical ApplicationData Download

-

High strand strength, low fuzz

Geotextiles

Roving for molded grating

-

Product CodeProduct FeaturesTypical ApplicationData Download

-

Direct roving, soft yarn, low fuzz, compatible with resins , excellent mechanical properties of composite products

Molded grile

Roving for Light Weight fabrics

-

Product CodeProduct FeaturesTypical ApplicationData Download

-

Excellent weaving property, excellent mechanical properties of composite products

Light weight fabrics and multiaxial fabrics

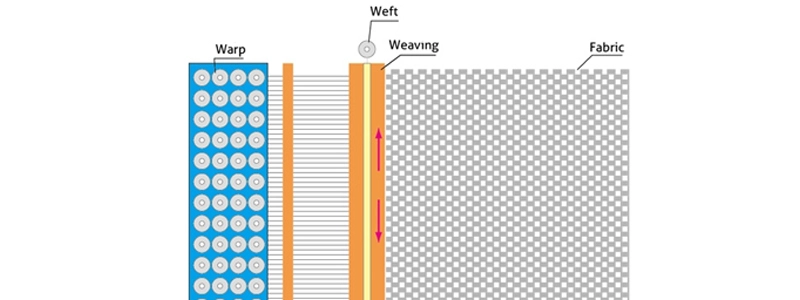

Mat Production Process

Assembled rovings are chopped to a specified length,and then fall onto a conveyor randomly. The chopped strands are bonded together by either an emulsion binder or a powder binder. After drying, cooling and winding, a chopped stand mat is formed.

Assembled Rovings for Chopped Strand Mats

Assembled Rovings for Chopped Strand Mats are specially used in powder or emulsion chopped strand mats, They have good choppability and dispersion and are compatible with unsaturated polyester, vinyl ester resins.

-

Product CodeProduct FeaturesTypical ApplicationData Download

-

General purpose roving, good dispersion after chopping, good static control and fast wet-out in resins

General chopped strand mats

-

General purpose roving, good dispersion after chopping, good static control and fast wet-out in resins

General chopped strand mats