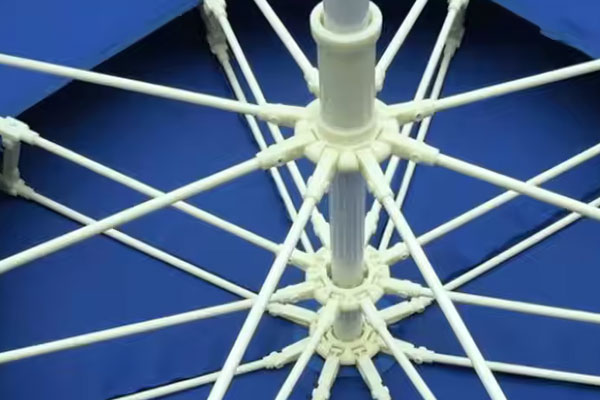

Fiberglass umbrella rib rods are critical components in modern umbrella design, offering a blend of strength, flexibility, and durability. This comprehensive guide explores their composition, advantages, technical specifications, manufacturing processes, comparisons with other materials, maintenance practices, and considerations for selection.

Product performance introduction

Composition and Manufacturing

Fiberglass umbrella ribs are constructed from fine glass fibers embedded within a resin matrix, resulting in a composite material that is both lightweight and robust. The manufacturing process typically involves pultrusion, where continuous strands of glass fibers are pulled through a resin bath and then through a heated die to form rods of consistent cross-section. This method ensures uniformity and allows for customization in terms of diameter, length, and flexibility.

Advantages of Fiberglass Umbrella Rib Rods

-

Flexibility and Wind Resistance: Fiberglass ribs can bend and flex under stress without breaking, allowing umbrellas to withstand high winds and adverse weather conditions. This flexibility enables the ribs to absorb wind gusts, reducing the risk of damage.

-

Durability and Longevity: Fiberglass ribs are resistant to rust, corrosion, and decay, ensuring a longer lifespan compared to traditional metal or wood ribs. They maintain their shape and functionality over time, even when exposed to harsh environmental conditions.

-

Lightweight: Despite their strength, fiberglass ribs are relatively lightweight, contributing to the overall ease of handling and transportation of the umbrella.

-

Non-Conductive: Fiberglass is a non-conductive material, reducing the risk of electrical hazards during thunderstorms.

Technical Specifications

When evaluating fiberglass umbrella rib rods, several technical parameters are essential:

-

Diameter and Thickness: Common diameters for fiberglass ribs range from 0.302 inches (approximately 7.67mm) to 0.75 inches (approximately 19.05mm). The choice of diameter affects the rib's strength and flexibility. For instance, larger canopies may require thicker ribs for adequate support.

-

Length: The length of the ribs corresponds to the size of the umbrella canopy. Standard lengths vary, with common sizes supporting canopies ranging from 6 feet to 11 feet in diameter.

-

Weight: The weight of fiberglass ribs contributes to the overall weight of the umbrella. While specific weights vary based on dimensions, fiberglass ribs are generally lighter than their metal counterparts, enhancing portability.

-

Flexural Strength: Fiberglass ribs are designed to flex under load without permanent deformation. This characteristic is quantified by flexural strength, indicating the maximum stress the material can withstand before failure.

Comparison with Other Materials

When choosing between fiberglass and other materials for umbrella ribs, it's essential to consider the following factors:

-

Strength-to-Weight Ratio: Fiberglass offers an excellent strength-to-weight ratio, providing robust support without excessive weight.

-

Durability: Unlike metal ribs, which may bend or corrode, or wood ribs, which can rot or warp, fiberglass ribs maintain their integrity over time with minimal maintenance.

-

Cost: Fiberglass ribs may have a higher upfront cost compared to some materials but offer greater longevity and reduced replacement frequency, potentially leading to cost savings over time.

Maintenance and Care

To extend the lifespan of fiberglass umbrella ribs:

-

Regular Inspection: Periodically check for signs of wear, cracks, or splinters.

-

Cleaning: Wipe down ribs with a damp cloth to remove dirt and debris. Avoid using harsh chemicals that may degrade the resin.

-

Storage: Store umbrellas in a dry place when not in use to prevent unnecessary exposure to environmental stressors.

-

Handling: Avoid applying excessive force or bending the ribs beyond their designed flexural capacity to prevent structural damage.

Selection Considerations

When selecting fiberglass umbrella ribs:

-

Umbrella Size and Design: Ensure the ribs' specifications align with the umbrella's dimensions and structural requirements. Larger canopies may necessitate thicker or more robust ribs.

-

Environmental Conditions: Consider the typical weather conditions the umbrella will face. In windy areas, opt for ribs designed to flex and absorb gusts without breaking.

-

Aesthetic Preferences: Fiberglass ribs can be manufactured in various finishes and colors to match the desired aesthetic of the umbrella.

-

Budget: Balance cost with quality. Investing in higher-quality fiberglass ribs can offer better performance and longevity, providing greater value over time.

Fiberglass umbrella rib rod

Series :

Main Products >application

tents, bags, umbrellas, sails, fitness equipment, arrows, antennas, flags, tarp containment, clubs, advertising display racks, windmills, fan stands, , transmission shafts of PCB equipment, sea sports equipment

Brand name :

TFcomposite

Product name :

Fiberglass umbrella rib rod

Material :

Fiberglass

Color :

White, Black

Finish Processing :

Smooth

FAQ

Q :

Are fiberglass rods stronger?

A :

The fiberglass material is much stronger and can withstand harsh job site conditions.

Q :

Do fiberglass rods break easy?

A :

The fibers stretch much more than graphite fibers so the rod will bend much deeper without breaking. They are also much less likely to be damaged by physical blows.

Other related products