Fiberglass tent poles are crafted from a composite material consisting of glass fibers embedded within a resin matrix. This combination results in a material that is both lightweight and durable. The manufacturing process involves pultrusion, where continuous strands of glass fibers are pulled through a resin bath and then through a heated die to form rods of consistent cross-section. This method ensures uniformity and allows for customization in terms of diameter, length, and flexibility.

Présentation des performances du produit

Advantages of Fiberglass Tent Poles

-

Cost-Effectiveness: Fiberglass poles are generally more affordable than their aluminum counterparts, making them a popular choice for budget-conscious campers.

-

Résistance à la corrosion: Unlike metal poles, fiberglass does not corrode when exposed to moisture, ensuring longevity even in humid or coastal environments.

-

La flexibilité: Fiberglass offers a degree of flexibility, allowing the poles to bend under stress without breaking immediately. This can be advantageous in windy conditions where some give is necessary.

-

Non conductrice: Being non-metallic, fiberglass poles do not conduct electricity, reducing the risk of lightning strikes—a consideration for campers in storm-prone areas.

Spécifications techniques

When evaluating fiberglass tent poles, several technical parameters are essential:

-

Diameter and Wall Thickness: Common diameters range from 6.3mm to 12.7mm. The wall thickness affects the pole's strength and flexibility. For instance:

-

6.3mm (1/4") Diameter: Suitable for lightweight tents; offers a bend radius of approximately 18 inches.

-

9.5mm (3/8") Diameter: Common in family dome tents; bend radius around 42 inches.

-

11mm (7/16") Diameter: Used for larger tents requiring more structural support; bend radius about 48 inches.

-

-

Longueur: Poles are typically segmented, with each section ranging from 25 to 27 inches. These segments are connected via ferrules and elastic shock cords for easy assembly and disassembly.

-

Lester: Weight varies based on diameter and length. For example, a 9.5mm diameter fiberglass pole section weighs approximately 4 ounces.

-

Bend Radius: This indicates the curvature a pole can achieve without compromising integrity. Larger diameters generally have larger bend radii, affecting the tent's shape and stability.

Comparison with Aluminum Tent Poles

When choosing between fiberglass and aluminum tent poles, it's essential to consider the following factors:

-

Strength-to-Weight Ratio: Aluminum poles typically offer a higher strength-to-weight ratio, making them suitable for heavy-duty applications.

-

Durabilité: Aluminum poles tend to bend under extreme stress, allowing for field repairs. In contrast, fiberglass poles may splinter or crack, necessitating replacement.

-

Weather Resistance: Fiberglass poles perform well in various weather conditions due to their corrosion resistance. However, they can become brittle in extremely cold temperatures.

-

Coût: Fiberglass poles are generally more affordable, making them a preferred choice for casual or budget campers.

Maintenance and Care

To extend the lifespan of fiberglass tent poles:

-

Regular Inspection: Before and after each use, check for signs of wear, cracks, or splinters.

-

Nettoyage: Wipe down poles with a damp cloth to remove dirt and debris. Avoid using harsh chemicals that may degrade the resin.

-

Stockage: Store poles in a cool, dry place away from direct sunlight to prevent UV degradation.

-

Manutention: Avoid stepping on or bending poles beyond their specified bend radius to prevent structural damage.

Selection Considerations

When selecting fiberglass tent poles:

-

Tent Size and Design: Ensure the poles' specifications align with the tent's dimensions and structural requirements.

-

Environmental Conditions: Consider the typical weather conditions you'll encounter. For instance, if camping in windy areas, opt for poles with a larger diameter for added strength.

-

Weight Constraints: For backpacking, lighter poles are preferable. Assess the trade-off between weight and durability based on your needs.

-

Budget: Balance cost with quality. While fiberglass poles are economical, investing in higher-quality options can offer better performance and longevity.

Conclusion

Fiberglass tent poles offer a harmonious blend of affordability, functionality, and resilience, making them a staple in the camping community. By understanding their properties, technical specifications, and maintenance needs, campers can make informed decisions, ensuring their shelters remain sturdy and reliable in diverse outdoor scenarios.

Poteaux de tente en fibre de verre

Série :

Principaux produits >application

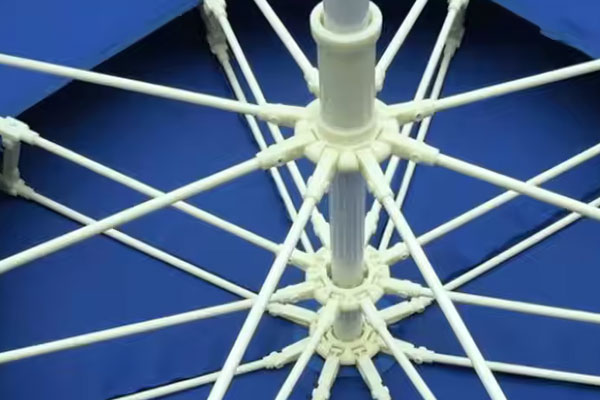

tentes, sacs, parapluies, voiles, équipements de fitness, flèches, antennes, drapeaux, bâches de confinement, clubs, présentoirs publicitaires, éoliennes, supports de ventilateurs, arbres de transmission d'équipements PCB, équipements de sports nautiques

Marque :

TFcomposite

Nom du produit :

Poteaux de tente en fibre de verre

Matériel :

Fibre de verre

Couleur :

Blanc noir

Traitement de finition :

Lisse

FAQ

Q :

Les tiges en fibre de verre sont-elles plus solides ?

UN :

Le matériau en fibre de verre est beaucoup plus résistant et peut résister aux conditions difficiles du chantier.

Q :

Les tiges en fibre de verre se cassent-elles facilement ?

UN :

Les fibres s'étirent beaucoup plus que les fibres de graphite, de sorte que la tige se pliera beaucoup plus profondément sans se casser. Ils sont également beaucoup moins susceptibles d'être endommagés par des coups physiques.

Autres produits connexes