Pultrusion roving is a specially engineered reinforcement material made from continuous strands of glass fibers bundled together without twist, optimized for use in pultrusion manufacturing. In this process, rovings are continuously drawn through a resin bath and then into a heated die to form rigid, lightweight, and high-strength composite profiles.

Présentation des performances du produit

This product plays a central role in determining the final composite’s mechanical performance, surface quality, dimensional accuracy, et resin compatibility. Compared to other roving types, pultrusion rovings exhibit excellent linear tension consistency, superior resin wet-out characteristics, and optimized sizing chemistry to match specific thermoset or thermoplastic matrices.

2. Overview of the Pultrusion Process

Pultrusion is a continuous manufacturing process for producing linear, constant cross-section composite profiles. The process is efficient, highly automated, and ideal for high-volume production of items such as beams, rods, ladders, window frames, gratings, and cable trays.

Pultrusion Workflow:

-

Fiber Delivery: Pultrusion rovings are unwound from creels and guided into a resin bath.

-

Resin Impregnation: Fibers are thoroughly wetted in a resin matrix (polyester, vinyl ester, epoxy).

-

Preforming: Wet fibers are guided into the shape of the final profile.

-

Heating & Curing: Material enters a heated steel die where the resin cures and the profile is shaped.

-

Pulling & Cutting: Hardened composite is continuously pulled from the die and cut to length.

3. Pultrusion Roving Product Characteristics

| Fonctionnalité | Benefit |

|---|---|

| No Twist | Enables excellent wet-out and uniform fiber alignment |

| Tailored Sizing | Improved chemical bonding with specific resins (polyester, epoxy, etc.) |

| Haute résistance à la traction | Delivers structural integrity to final composite products |

| Low Fuzz and Breakage | Enables smooth running during high-speed production |

| Controlled Tex Values | Optimized for volume fraction and line speed control |

| Excellent Wet-Out | Ensures void-free, high-density composites |

| Dimensional Stability | Critical for tight-tolerance pultruded profiles |

4. Applications of Pultrusion Roving

Pultrusion rovings are used across various industries for structural and semi-structural applications.

4.1 Construction & Infrastructure

-

FRP rebar

-

Cable trays and ladders

-

Gratings and decking systems

-

Handrails, fencing, doors, and window frames

4.2 Electrical & Utility

-

Non-conductive utility poles

-

Crossarms and insulators

-

Transformer insulation components

4.3 Marine & Offshore

-

Boat hull reinforcements

-

Dock panels and marine beams

-

Corrosion-resistant offshore gratings

4.4 Automotive & Transportation

-

Lightweight interior/exterior parts

-

Reinforcement in truck trailers and RVs

-

Structural supports and chassis components

4.5 Renewable Energy

-

Wind turbine spar caps and frames

-

Solar panel supports

5. Technical Performance Requirements

Pultrusion roving must deliver consistently high performance in multiple aspects:

| Requirement | Typical Specification |

|---|---|

| Linear Density (Tex) | 2400, 4800, 9600 (custom options available) |

| Résistance à la traction | ≥ 2300 MPa |

| Elongation at Break | 2.0 – 2.5% |

| Loss on Ignition (LOI) | 0.80 – 1.20% |

| Compatibilité résine | Tailored sizing for epoxy, polyester, or vinyl ester resins |

| Wet-Out Speed | ≤ 30 seconds in standard polyester resins |

| Diamètre des filaments | 13 – 24 µm, typically 17 µm or 24 µm |

| Creel & Unwind Performance | Stable tension, low fuzz, no snags or dry-out |

6. Advantages of Pultrusion Roving

-

High Production Efficiency: Engineered for fast-line speeds and minimal downtime.

-

Consistent Wet-Out: Reduces voids and enhances interfacial bonding.

-

Excellent Surface Finish: Results in smooth, cosmetically attractive parts.

-

Précision dimensionnelle: Minimizes part distortion and improves mold release.

-

Long-Term Durability: Resistance to corrosion, moisture, UV, and chemicals.

7. TDS – Technical Data Sheet

Nom du produit: Pultrusion Roving

Glass Type: E-glass

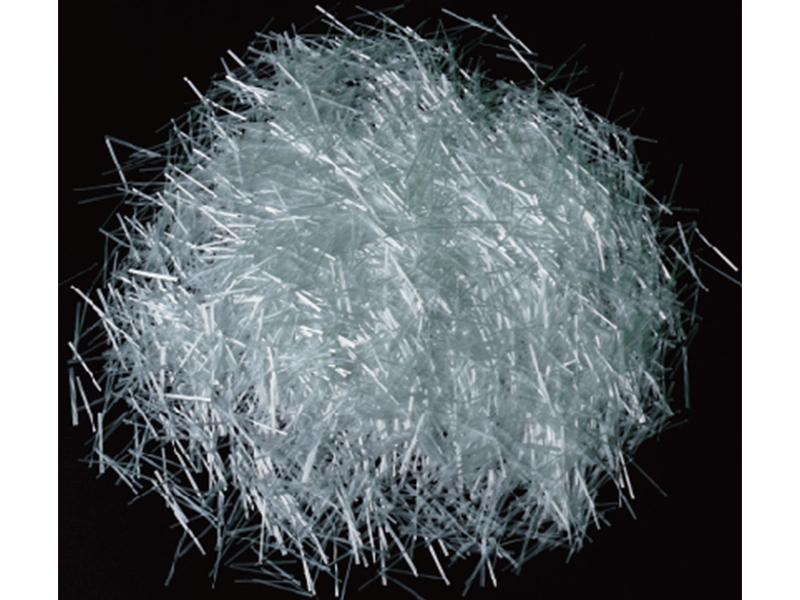

Form: Untwisted continuous strand roving

Standard Tex Values: 2400 / 4800 / 9600

7.1 Physical Properties

| Propriété | Typical Value | Méthode d'essai |

|---|---|---|

| Linear Density (Tex) | 2400 / 4800 / 9600 | OIN 1889 |

| Diamètre des filaments | 17 µm / 24 µm | ISO 1888 |

| Moisture Content | ≤ 0.10% | OIN 3344 |

| Loss on Ignition (LOI) | 0.80 – 1.20% | OIN 1887 |

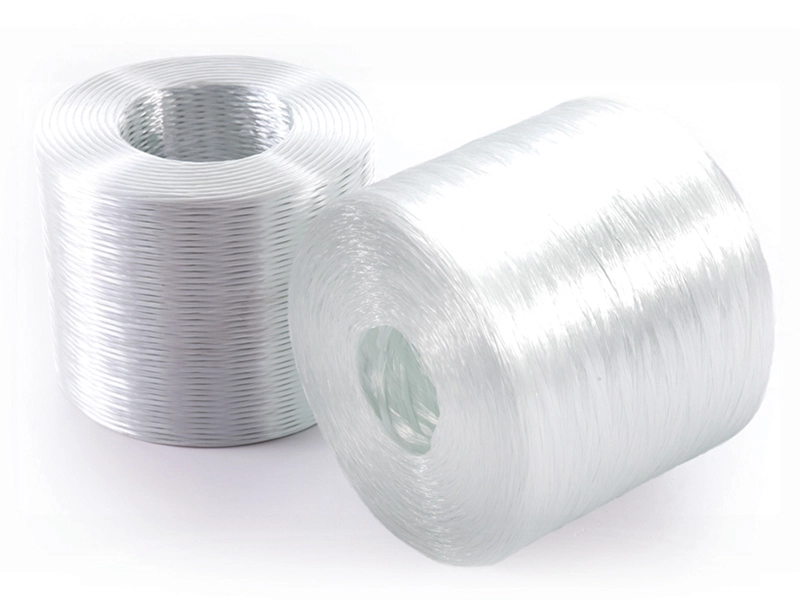

| Bobbin Weight | 15 – 25 kg | Internal Standard |

| Bobbin Inner Diameter | 76 mm (3 inch) | Manufacturer Specification |

| Bobbin Outer Diameter | ~270 mm | Manufacturer Specification |

| Couleur | White | Visual |

7.2 Mechanical Properties

| Propriété | Typical Value | Méthode d'essai |

|---|---|---|

| Résistance à la traction | ≥ 2300 MPa | ASTM D2343 |

| Tensile Modulus | ≥ 72 GPa | ASTM D2343 |

| Elongation at Break | 2.0 – 2.5% | ASTM D2343 |

| Sizing Compatibility | Excellent (Polyester/Epoxy) | Wet-Out Visual Rating |

| Resin Wet-Out Time | ≤ 30 seconds | In-house Process Test |

| Static Buildup | Very Low | Observation |

8. Packaging and Labeling

Emballage

-

Bobbins individually shrink-wrapped and arranged on pallets

-

Pallet Size: 1100 mm × 1100 mm, 48–64 bobbins per pallet

-

Stretch-wrapped with corner protection

-

Optional: Vacuum-packed packaging for extended shelf life

Labeling

Each bobbin is labeled with:

-

Code produit

-

Tex/yield

-

Net/gross weight

-

Batch number

-

Date of manufacture

-

Sizing compatibility information

9. Storage and Shelf Life

| Paramètre | Recommended Condition |

|---|---|

| Temperature | 15 – 35°C |

| Humidity | ≤ 65% RH |

| Shelf Life | 12 months (extendable to 24 in climate control) |

| Storage Advice | Store indoors, avoid sunlight and moisture |

Rovings should be conditioned in the production environment for at least 24 hours before use to avoid thermal shock or moisture-related processing issues.

10. Processing Guidelines

| Paramètre | Recommended Practice |

|---|---|

| Resin Viscosity | 300 – 1000 cps (application specific) |

| Fiber Tension | 1.2 – 2.5 N per strand depending on tex |

| Line Speed | 0.5 – 2.5 m/min (depending on profile size and resin cure) |

| Die Temperature | 120 – 160°C |

| Catalyst % (for polyester) | 0.8 – 2.0% (MEKP, BPO) |

| Wet-Out Monitoring | Use visual or ultrasonic scanners to check air bubbles |

| Preforming | Preform guides should match profile geometry |

11. Quality Control and Certifications

| Certification/Standard | Description |

|---|---|

| ISO 9001 | Quality Management System |

| ISO 14001 | Environmental Management |

| RoHS Compliant | Free of restricted substances |

| REACH Compliant | Conforms to EU chemical safety standards |

| UL, ASTM Testing | Available for fire, electrical, mechanical properties |

12. Environmental and Safety Considerations

Environmental Attributes

-

Inert and non-toxic

-

Long service life (20+ years in corrosive environments)

-

100% recyclable for use as filler in concrete or thermoplastic compounds

Health & Safety

-

Use PPE during handling (gloves, masks)

-

Avoid inhalation of dust from dry or cut fibers

-

Wash hands after handling

Refer to the Material Safety Data Sheet (MSDS) for detailed hazard and first aid information.

13. Customization Options

Manufacturers can provide pultrusion rovings customized to your application:

-

Tex Customization: Any linear density (1800 to 9600 tex)

-

Filament Size: Fine (13 µm) to coarse (24 µm) for varying stiffness needs

-

Resin System: Tailored sizings for epoxy, polyester, vinyl ester, polyurethane

-

Bobbin Format: Cylindrical, tapered, or high-yield formats

-

Color-Coding: Colored tracer filaments for process identification

14. Manufacturer Support Services

Leading suppliers provide:

-

On-site trial support and optimization

-

Technical training for pultrusion line setup

-

Roving evaluation reports and testing

-

Custom sizing development for emerging resin technologies

-

Co-development of new composite profiles

15. Conclusion

Pultrusion roving is a high-performance, tailored reinforcement material essential to the success of continuous profile production in composites. Whether for structural beams, electrical insulators, or transportation components, this product offers superior mechanical strength, easy resin wet-out, and process efficiency.

With its unmatched ability to deliver dimensionally stable, void-free, corrosion-resistant profiles, pultrusion roving continues to drive innovation in FRP applications across the globe.

Pultrusion Roving

application

Automobile / Biens de consommation et équipements professionnels / Sports et loisirs / Électricité et électronique / Bâtiment et construction / Infrastructure

Type de verre :

E

Nom du produit :

Pultrusion Roving

FAQ

Q :

Êtes-vous une usine? Où es-tu situé?

UN :

Nous sommes fabricant de caillebotis FRP et de profilés pultrudés, commerçant de matériaux en fils FRP. Nous sommes le plus grand distributeur de China Jushi Co. Nous vendons également des produits de plusieurs fabricants de fils FRP. Nous sommes à Anhui, en Chine.

Q :

Quelles informations sont recommandées pour l'enquête?

UN :

1. De quel tex avez-vous besoin ? 2. Pour quelle application l'utilisez-vous ? Ou la technologie, est-ce le tissage, la pultrusion ou le bobinage ? 3. De quelle quantité avez-vous besoin ? 4. Pour quelle résine combinez-vous ? Résine polyester ou résine époxy ? 5. Avez-vous besoin d'un prix FOB ou CIF, si CIF, veuillez nous indiquer votre port.

Q :

Quel est le MOQ?

UN :

Habituellement 1 tonne

Q :

Emballage et expédition

UN :

Emballage normal : carton (inclus dans le prix unitaire) Emballage spécial : besoin de facturer en fonction de la situation réelle. Expédition normale : votre expédition de fret désignée.

Q :

Quand puis-je offrir ?

UN :

Nous citons généralement dans les 24 heures après réception de votre demande. Si vous êtes très urgent d'obtenir le prix, veuillez nous appeler ou nous le dire dans votre e-mail, afin que nous puissions vous répondre en priorité.

Q :

Comment facturez-vous les frais d’échantillonnage ?

UN :

Si vous avez besoin d'échantillons de notre stock, nous pouvons vous les fournir gratuitement, mais vous devez payer les frais de transport. Si vous avez besoin d'une taille spéciale, nous facturerons les frais de fabrication d'échantillons qui sont remboursables lorsque vous passez une commande.

Q :

quel est votre délai de livraison pour la production?

UN :

Si nous avons des actions, pouvons la livraison en 7 jours ; Si sans le stock, besoin de 7 à 15 jours !

Autres produits connexes