Fiberglass stair treads and stair covers are an essential complement to molded and pultruded grating installations.

Présentation des performances du produit

Fiberglass stair treads are essential components in industrial, commercial, and residential applications where safety, durability, and resistance to harsh environments are critical. Engineered from fiberglass-reinforced plastic (FRP), these stair treads provide a slip-resistant, corrosion-resistant, and lightweight solution for both indoor and outdoor stairways. This guide explores the components, specifications, advantages, and applications of fiberglass stair treads in detail.

1. Components of Fiberglass Stair Treads

Fiberglass stair treads are constructed with several critical elements, each contributing to their superior performance and longevity:

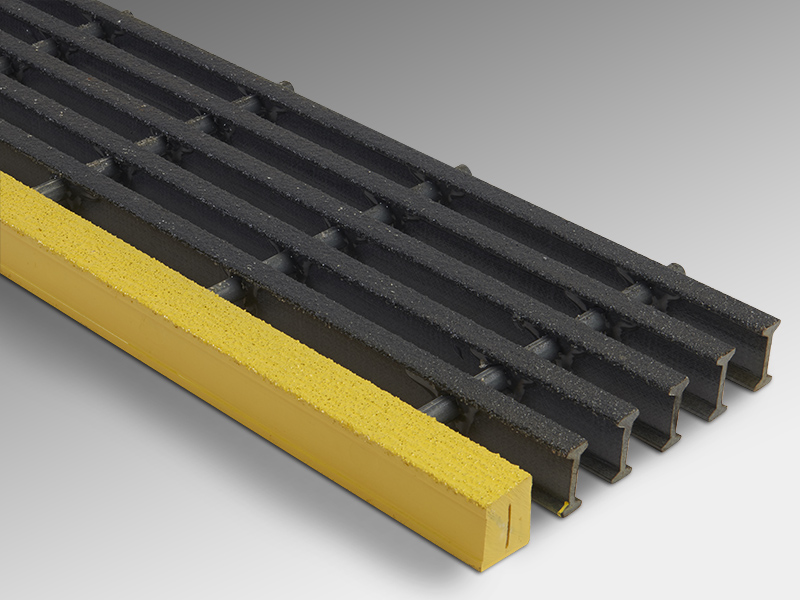

1.1. FRP Grating Base

- Purpose: Serves as the primary structural component, providing strength and durability.

- Matériel: Made from FRP, combining a resin matrix (polyester, vinyl ester, or phenolic) with continuous fiberglass reinforcements for high strength-to-weight ratios.

- Types:

- Grille moulée: Uniform distribution of load, ideal for heavy-duty applications.

- Grille Pultrudée: High stiffness and long-span capability, suitable for large-scale installations.

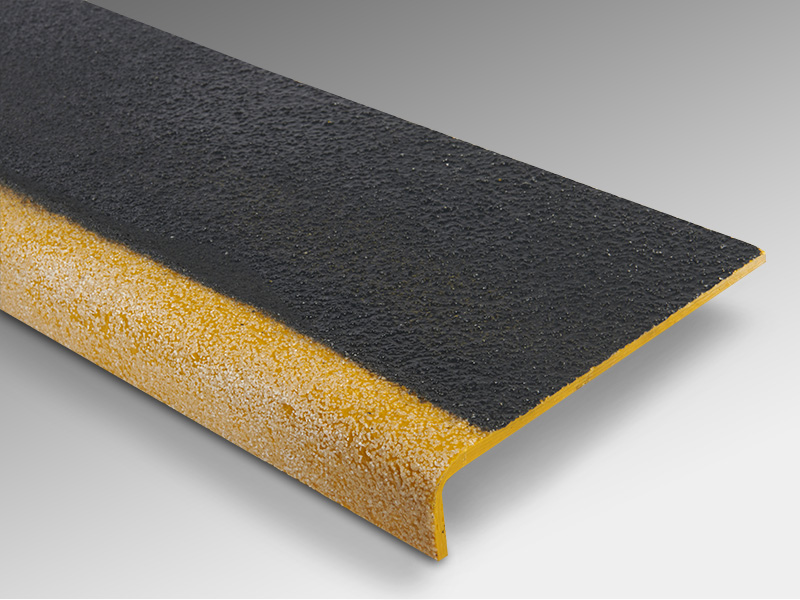

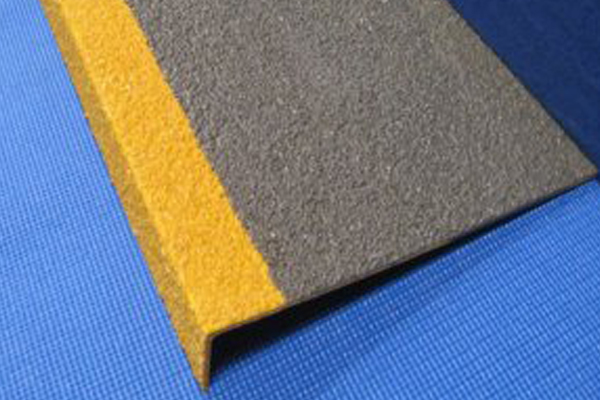

1.2. Anti-Slip Surface

- Purpose: Ensures safety by reducing the risk of slips and falls, especially in wet or oily conditions.

- Designs:

- Surface sablée: Coated with silicon carbide or aluminum oxide for maximum traction.

- Smooth Surface with Nosings: Adds slip resistance while providing a visually appealing finish.

- Personnalisation: Available in different grit levels based on the intended environment.

1.3. Stair Nosing

- Purpose: Enhances visibility and edge protection while contributing to the slip-resistant properties.

- Matériel: FRP or embedded abrasive grit material.

- Options de couleur: Bright, contrasting colors like yellow or reflective finishes for enhanced visibility.

1.4. Reinforcing Bars

- Purpose: Provide additional strength and support for heavy-duty applications.

- Matériel: Pultruded fiberglass bars integrated into the structure of the stair tread.

1.5. Mounting Hardware

- Purpose: Securely fastens the stair treads to the underlying structure.

- Matériel: Corrosion-resistant materials such as stainless steel, galvanized steel, or FRP.

2. Specifications of Fiberglass Stair Treads

Fiberglass stair treads are designed and manufactured to meet specific mechanical, chemical, and safety standards. Below are the common specifications:

2.1. Material Composition

- Types de résine:

- Polyester Resin: Cost-effective, suitable for general-purpose applications.

- Résine vinylester: Superior resistance to chemical corrosion, ideal for harsh industrial environments.

- Résine phénolique: Excellent fire resistance and low smoke emission, often used in transit systems and offshore applications.

- Contenu en fibre de verre: Typically ranges from 35% to 65%, ensuring high strength and durability.

2.2. Structural Properties

- Capacité de chargement: Designed to support heavy loads, with capacities ranging from 500 lbs to over 2,000 lbs per square foot.

- Span Lengths: Available in various span lengths, typically between 18 inches to 48 inches, to suit different applications.

- Résistance aux chocs: Excellent resistance to impact and deformation under dynamic loads.

2.3. Dimensions

- Tailles standards: Common widths range from 8 inches to 12 inches, with lengths up to 48 inches or customized sizes available.

- Épaisseur: Typically ranges from 1 inch to 2 inches, depending on the application requirements.

- Tread Depth: Standard tread depths range from 10 inches to 12 inches for comfortable and safe stepping.

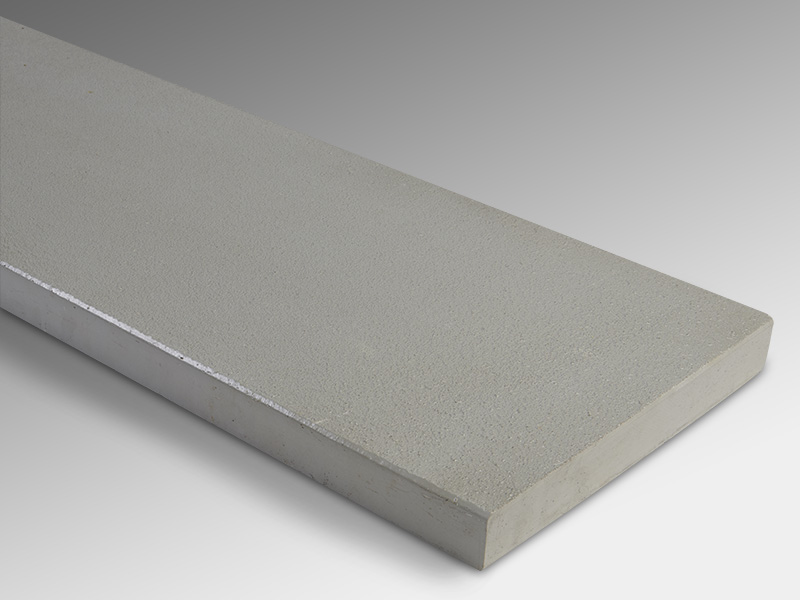

2.4. Surface Finishes

- Gritted Finish: Provides optimal traction and durability, even in wet or oily conditions.

- Smooth Finish: For less abrasive environments while still maintaining slip resistance.

- UV-Stabilized Coating: Prevents degradation from prolonged exposure to sunlight.

2.5. Environmental Resistance

- Résistance à la corrosion: Highly resistant to chemicals, saltwater, and other corrosive agents.

- Temperature Range: Operates effectively in environments ranging from -40°C to +70°C.

- Classement au feu: Meets ASTM E84 Class 1 standards for flame spread and smoke development.

2.6. Color Options

- Standard colors include gray, yellow, and green, with custom colors available for branding or safety marking.

2.7. Compliance Standards

- ASTM Standards: Meets mechanical and safety requirements.

- OSHA Compliance: Conforms to workplace safety standards for slip resistance and load-bearing capacity.

- ISO Certification: Manufactured under ISO 9001 quality management systems.

3. Advantages of Fiberglass Stair Treads

Fiberglass stair treads provide numerous benefits compared to traditional materials like wood, steel, or aluminum:

3.1. Corrosion Resistance

Unlike metal treads, fiberglass stair treads resist corrosion caused by chemicals, moisture, and salt, making them ideal for harsh industrial and marine environments.

3.2. Slip Resistance

The anti-slip surface ensures superior traction, reducing accidents even in wet, icy, or oily conditions.

3.3. Lightweight Construction

FRP materials are significantly lighter than steel, simplifying installation and reducing handling costs.

3.4. High Strength-to-Weight Ratio

Despite their lightweight nature, fiberglass stair treads have exceptional strength and durability, supporting heavy loads with ease.

3.5. Maintenance-Free

Fiberglass stair treads do not rust, warp, or require frequent painting or repairs, significantly reducing long-term maintenance costs.

3.6. Customizability

Easily fabricated to meet specific project requirements, including unique shapes, colors, and sizes.

3.7. Non-Conductive

Fiberglass is non-conductive, providing an added layer of safety in environments with electrical equipment or high voltage.

3.8. Longevity

With a service life often exceeding 20 years, FRP stair treads are a cost-effective solution over time.

4. Applications of Fiberglass Stair Treads

Fiberglass stair treads are used across various industries and environments due to their versatility and resilience:

4.1. Industrial Facilities

- Platforms, walkways, and staircases in chemical plants, refineries, and factories.

- Resistant to chemical exposure and heavy foot traffic.

4.2. Marine Environments

- Offshore platforms, docks, and ship decks where saltwater corrosion is a concern.

4.3. Public Infrastructure

- Parks, pedestrian bridges, and public stairways.

- UV-resistant and suitable for all-weather use.

4.4. Transportation

- Railways, subways, and airports.

- Phenolic resin treads for fire resistance and low smoke emission.

4.5. Wastewater Treatment

- Walkways and stairs in clarifiers, aeration tanks, and pump stations.

- High corrosion resistance ensures longevity.

4.6. Commercial and Residential Applications

- Staircases in offices, schools, and residential buildings.

- Aesthetic finishes and customizable colors for modern designs.

5. Maintenance and Installation

5.1. Installation

- Easy to install using pre-drilled holes, mounting brackets, or adhesives.

- Lightweight construction minimizes the need for heavy equipment.

5.2. Maintenance

- Requires minimal upkeep; regular cleaning with mild detergents and water is sufficient.

- Resistant to rust and other common issues, ensuring long-lasting performance.

6. Tendances futures

Fiberglass stair treads continue to evolve with advancements in materials and manufacturing technologies. Future trends include:

- Formulations de résine améliorées: Enhancing fire resistance and chemical compatibility.

- Durabilité: Increased use of recyclable materials and eco-friendly production methods.

- Smart Integration: Incorporation of embedded sensors for monitoring usage and wear.

Conclusion

Fiberglass stair treads are a superior choice for applications requiring safety, durability, and resistance to harsh environments. With customizable designs, compliance with safety standards, and low maintenance requirements, they offer a cost-effective, long-term solution for a wide range of industries. Whether for industrial, marine, or public infrastructure, fiberglass stair treads deliver performance and reliability in even the most demanding conditions.

Fiberglass Stair Treads - Slip-Resistant and Durable

Série :

Fiberglass Stair Treads >application

FAQ

Autres produits connexes