FRP (Fiberglass Reinforced Plastic) Cooling Towers are highly durable, corrosion-resistant solutions for industrial and HVAC cooling applications. Designed to offer optimal thermal performance, mechanical strength, and low maintenance, these towers utilize the superior mechanical properties of FRP to deliver reliable service life in the most demanding environments.

Présentation des performances du produit

Unlike traditional galvanized or metal cooling towers, FRP Cooling Towers do not corrode when exposed to water, chemicals, or varying atmospheric conditions, making them ideal for installations in coastal regions, chemical processing plants, power stations, refineries, steel mills, and large commercial complexes.

Structure and Design

The body of the FRP Cooling Tower is made of high-quality fiberglass-reinforced polyester resins, which are UV-resistant and engineered to resist chemicals and weathering. The modular design enables easy assembly and scalability. The surface is coated with UV-stabilized gelcoat or vinyl ester topcoats to prevent degradation due to prolonged exposure to sunlight or aggressive agents.

These towers are available in both counterflow et crossflow configurations, with round or rectangular designs, tailored to meet specific client requirements.

Principales caractéristiques

-

Résistance à la corrosion: FRP construction resists rust and degradation from acids, alkalis, moisture, and air pollution.

-

Lightweight & Durable: Easier to install and relocate compared to metal or concrete towers.

-

Energy Efficient: Equipped with energy-efficient motors and aerodynamic fans that reduce power consumption.

-

Faible entretien: FRP requires minimal maintenance due to its non-metallic, anti-fungal, and anti-bacterial surface.

-

Noise Control: Incorporates low-noise fan technology and optimized water distribution for quieter operation.

-

Personnalisation: Available in various capacities (10 TR to 1000+ TR) and configurations (induced draft, forced draft, bottle type, rectangular type).

Applications

-

HVAC systems in commercial buildings

-

Chemical and petrochemical plants

-

Steel and metallurgy industries

-

Power generation plants

-

Plastic injection molding and extrusion

-

Textile and paper mills

Technical Data Sheet (TDS) – FRP Cooling Tower

| Paramètre | spécification |

|---|---|

| Matériel | FRP (Glass Fiber Reinforced Polyester Resin) |

| Taper | Induced Draft / Forced Draft; Counterflow or Crossflow |

| Plage de capacité | 10 TR to 1500+ TR |

| Casing Thickness | 4 mm – 8 mm (customizable) |

| Fill Media | PVC / PP Honeycomb / Film Type / Splash Type (custom options) |

| Water Flow Rate | 1 – 3000 m³/hr |

| Heat Dissipation | 3000 – 500,000 kcal/hr (depending on model) |

| Fan Material | Aluminum / FRP / Polypropylene, Balanced for Low Noise |

| Moteur | TEFC (Totally Enclosed Fan Cooled), IP55, Class F |

| Drift Loss | < 0.02% of circulating water flow |

| Operating Temperature | 4°C to 55°C |

| Inlet/Outlet Connections | FRP Flanged / PVC / SS316, customizable based on requirement |

| Noise Level | < 70 dB(A) @ 1 meter |

| Résistance aux UV | Yes, with gel coat finish |

| Wind Load Tolerance | Up to 180 km/h (with structural reinforcement) |

| Life Expectancy | 15–25 years with proper maintenance |

| Certification | ISO 9001, CE, and optional CTI Certified |

Optional Components and Upgrades

-

Stainless steel or HDG support structures

-

Variable Frequency Drive (VFD) compatible motors

-

Basin heaters for cold weather conditions

-

Chemical dosing and water treatment systems

-

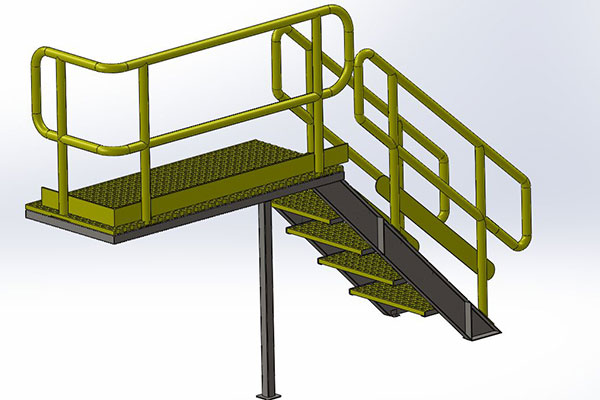

Maintenance ladders and platforms

FRP Cooling Tower

Série :

produits >application

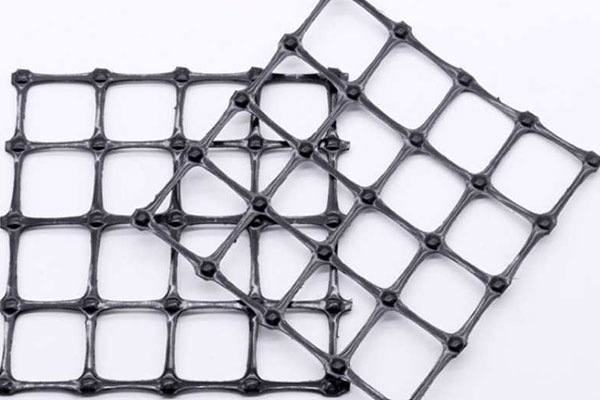

Fiberglass geogrids are primarily used in: Roadway and pavement reinforcement Slope stabilization Retaining walls Railway ballast stabilization Embankment and landfill stabilization Waste containment

Marque :

TFcomposite

Nom du produit :

FRP Cooling Tower

FAQ

Q :

What are the main advantages of using FRP Cooling Towers over metal ones?

UN :

Corrosion resistance (no rusting or oxidation) Lightweight for easier transport and installation Longer lifespan with minimal maintenance Better UV and weather resistance Customizable shapes and capacities Lower life-cycle cost despite higher initial price

Q :

What types of FRP Cooling Towers are available?

UN :

Bottle Type / Round Type – Compact, mostly for HVAC and smaller systems Rectangular Type – Modular, scalable for large industrial applications Induced Draft – Fan at the top pulls air upwards Forced Draft – Fan at the side pushes air through the fill Crossflow / Counterflow – Based on air-water flow direction

Q :

What is the typical service life of an FRP Cooling Tower?

UN :

With proper maintenance, an FRP cooling tower can last 15 to 25 years, significantly longer than mild steel or galvanized steel towers.

Q :

Can FRP Cooling Towers be used in coastal or chemical environments?

UN :

Yes. FRP is highly resistant to salt-laden air, acidic fumes, and aggressive chemical environments, making it ideal for coastal areas, chemical plants, and refineries.

Autres produits connexes