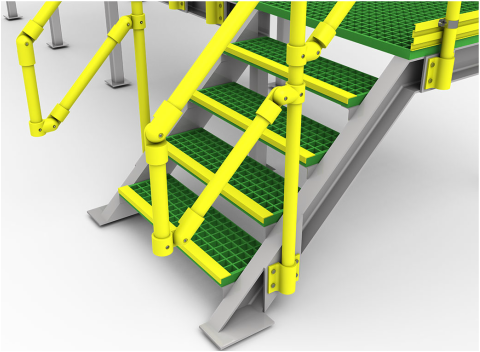

FRP Grating as Stair Treads Specifications Applications and Benefits

FRP (Fiber Reinforced Plastic) grating is a composite material known for its strength, durability, and resistance to environmental factors. When used as stair treads, FRP grating provides a safe, efficient, and cost-effective solution for a wide range of industries, including manufacturing, marine, construction, and public infrastructure. This comprehensive guide explores the design, features, specifications, and benefits of FRP grating as stair treads.

What Are FRP Grating Stair Treads?

FRP grating stair treads are prefabricated steps made from fiber-reinforced plastic grating. They are designed to provide a safe, slip-resistant walking surface on stairways, particularly in industrial or outdoor environments. The grating’s inherent properties—lightweight construction, corrosion resistance, and high strength-to-weight ratio—make it an ideal choice for stair treads in demanding settings.

Features of FRP Grating Stair Treads

-

Haute résistance et durabilité

- Engineered to support substantial loads without deforming or breaking.

- Offers long service life even in high-traffic areas.

-

Surface antidérapante

- Gritted or anti-slip surfaces provide excellent traction, reducing the risk of slips and falls.

-

Résistance à la corrosion

- Unaffected by exposure to chemicals, moisture, saltwater, and other corrosive elements, ensuring reliability in harsh environments.

-

Résistance au feu

- Available with fire-retardant resins to meet safety standards and prevent rapid flame spread.

-

Conception légère

- Easier to handle and install compared to traditional materials like steel or concrete.

-

Weather Resistance

- Maintains performance in extreme temperatures, UV exposure, and other environmental conditions.

-

Faible entretien

- Requires minimal upkeep, reducing lifecycle costs.

Materials Used in FRP Grating Stair Treads

The construction of FRP grating stair treads involves the following components:

-

Resin Systems

- Polyester Resin: Cost-effective and suitable for general-purpose applications.

- Vinyl Ester Resin: Offers enhanced chemical and corrosion resistance.

- Phenolic Resin: Provides excellent fire resistance and low smoke emission.

-

Reinforcement Fibers

- Glass fibers are the primary reinforcement, giving the grating its strength and rigidity.

-

Surface Coatings

- Anti-slip coatings, UV stabilizers, and fire-retardant treatments enhance safety and durability.

Design and Construction of FRP Grating Stair Treads

FRP grating stair treads are available in various designs to suit different applications:

-

Molded FRP Stair Treads

- Fabricated using a one-piece construction process, offering bi-directional strength and uniform load distribution.

- Typically features square or rectangular mesh patterns for debris drainage and ventilation.

-

Pultruded FRP Stair Treads

- Manufactured by pulling continuous glass fibers through a resin system, resulting in a high-strength, unidirectional structure.

- Often includes T-bar or I-bar profiles for superior stiffness.

-

Covered FRP Stair Treads

- Features a solid top surface for enhanced safety and easier cleaning.

- Ideal for applications where small objects or liquids might fall through the grating.

-

Customized FRP Stair Treads

- Can be tailored to specific dimensions, shapes, and color schemes to match unique project requirements.

Specifications of FRP Grating Stair Treads

1. Dimensions

- Standard Widths: 6", 8", 10", or custom sizes.

- Lengths: Available up to 12 feet, cut to fit stairway dimensions.

- Thickness: Common options include 1", 1.5", and 2".

2. Load-Bearing Capacity

- Designed to support pedestrian traffic and light equipment loads.

- Rated based on deflection limits per ASTM standards.

3. Options de surface

- Gritted Surface: For maximum slip resistance in wet or oily conditions.

- Concave Surface: Provides a smooth, slip-resistant profile.

4. Résistance au feu

- Meets ASTM E-84 Class A, B, or C fire ratings based on the application.

5. Options de couleur

- Standard colors include gray, yellow, green, and black.

- UV-resistant colors maintain vibrancy over time.

Applications of FRP Grating Stair Treads

FRP grating stair treads are used across various industries and environments due to their versatility and performance:

-

Installations industrielles

- Chemical plants, refineries, and factories often use FRP stair treads for their resistance to chemicals and heavy loads.

-

Marine and Offshore Platforms

- Ideal for docks, ship decks, and offshore oil rigs due to corrosion resistance and non-slip properties.

-

Water and Wastewater Treatment Plants

- Performs well in constantly wet and chemically harsh environments.

-

Public and Commercial Spaces

- Used in parks, recreational areas, and pedestrian walkways for safety and aesthetics.

-

Transportation and Infrastructure

- Found in railway platforms, stairways in transit systems, and pedestrian overpasses.

-

Construction Sites

- Temporary or permanent stair treads in scaffolding systems and access platforms.

Advantages of Using FRP Grating for Stair Treads

-

Sécurité améliorée

- Non-slip surfaces significantly reduce the risk of accidents, even in wet or oily conditions.

-

Corrosion-Free Performance

- Unlike metal, FRP grating doesn’t rust or degrade when exposed to harsh chemicals or seawater.

-

Facilité d'installation

- Lightweight construction reduces the need for heavy equipment or large crews during installation.

-

Customizability

- FRP grating stair treads can be tailored to fit any stairway design or dimension, offering flexibility in design.

-

Cost Savings

- The low maintenance requirements and long lifespan make FRP stair treads a cost-effective alternative to traditional materials.

-

Attrait esthétique

- Available in a variety of colors and finishes to enhance the visual appeal of stairways.

-

Environmental Friendliness

- FRP materials are recyclable and have a lower environmental impact than many traditional materials.

Installation of FRP Grating Stair Treads

1. Preparation

- Ensure the stairway structure is clean and free of debris.

- Measure and cut the grating to fit the dimensions of the stairs.

2. Fixing and Anchoring

- Attach the treads securely using stainless steel clips, bolts, or adhesive systems to prevent movement.

- Ensure proper alignment and spacing between steps.

3. Edge Protection

- Install kick plates or nosing strips to protect the edges from wear and enhance visibility.

4. Safety Testing

- Conduct load tests and slip-resistance checks to ensure compliance with safety standards.

Maintenance of FRP Grating Stair Treads

-

Regular Cleaning

- Remove dirt, grease, and debris using water and mild detergents.

-

Inspections

- Periodically check for signs of damage or wear, such as cracks or surface degradation.

-

Repairs and Replacement

- Damaged sections can be replaced without removing the entire stair tread.

-

Surface Treatments

- Reapply anti-slip coatings if necessary to maintain traction.

Standards and Certifications

FRP grating stair treads are designed to meet industry-specific safety and performance standards, such as:

-

ASTM Standards

- ASTM E-84 for flame spread and smoke development.

- ASTM D635 for horizontal burn rate.

-

OSHA Compliance

- Meets Occupational Safety and Health Administration requirements for slip resistance and load capacity.

-

ISO Standards

- ISO 11925 for fire testing of building materials.

-

BS Standards

- BS 476 for fire performance of materials.

Challenges in Using FRP Grating Stair Treads

-

Initial Cost

- Higher upfront cost compared to some traditional materials, though offset by long-term savings.

-

Customization Requirements

- Tailoring FRP grating to specific dimensions may extend lead times.

-

UV Degradation

- Prolonged exposure to sunlight can affect untreated surfaces, but UV-resistant coatings mitigate this issue.

-

Load Limitations

- May not be suitable for extremely heavy loads unless reinforced appropriately.

Conclusion

FRP grating stair treads combine safety, durability, and versatility, making them an excellent choice for various applications. Their non-slip surface, corrosion resistance, and lightweight design offer significant advantages over traditional materials like steel and wood. By adhering to industry standards and tailoring the design to specific requirements, FRP stair treads provide a long-lasting, cost-effective solution for creating safe and reliable stairways in industrial, commercial, and public environments.