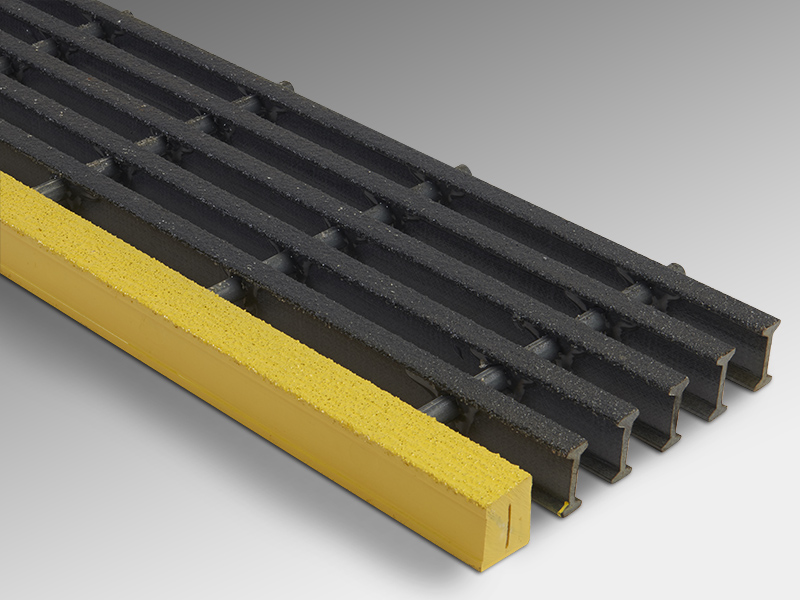

Fiberglass stair treads and stair covers are an essential complement to molded and pultruded grating installations.

Présentation des performances du produit

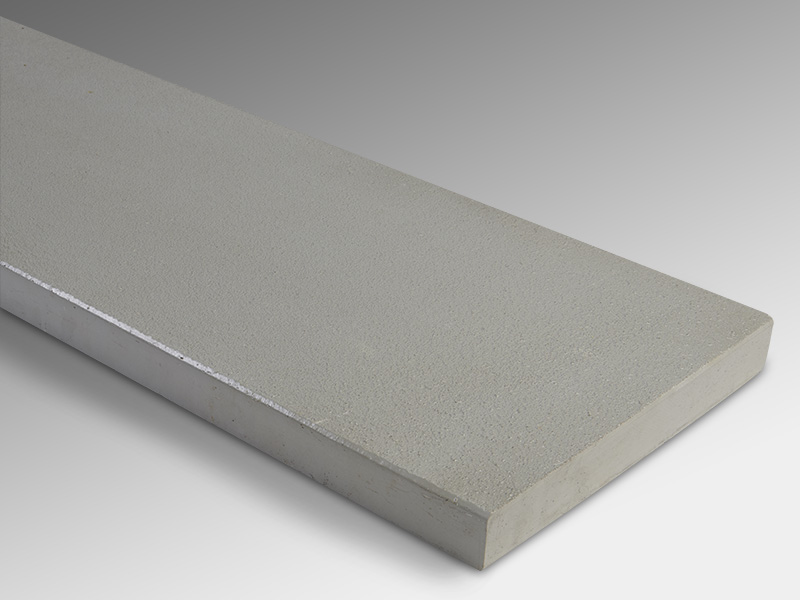

Fiber Reinforced Polymer (FRP) stair covers are an innovative solution designed to improve the safety, durability, and aesthetics of existing staircases. These covers are fabricated from high-strength fiberglass-reinforced polymer materials and are specifically designed to fit over worn, slippery, or damaged stairs. Offering a non-slip surface and exceptional resistance to environmental and mechanical stresses, FRP stair covers are ideal for a variety of settings, including industrial, commercial, and residential environments.

1. Material Composition

FRP stair covers are engineered using advanced composite materials to ensure long-lasting performance:

- Renfort en fibre de verre: Layers of fiberglass provide the necessary structural strength and flexibility.

- Resin Systems: Polyester, vinyl ester, or epoxy resins offer resistance to chemicals, moisture, and temperature extremes.

- Surface antidérapante: A gritted surface, often embedded with quartz, aluminum oxide, or silicon carbide, ensures excellent traction.

- UV Inhibitors: Optional additives prevent fading and degradation due to prolonged sun exposure, making them suitable for outdoor use.

- Fire Retardants: Fire-resistant formulations are available for compliance with safety regulations.

2. Design Features

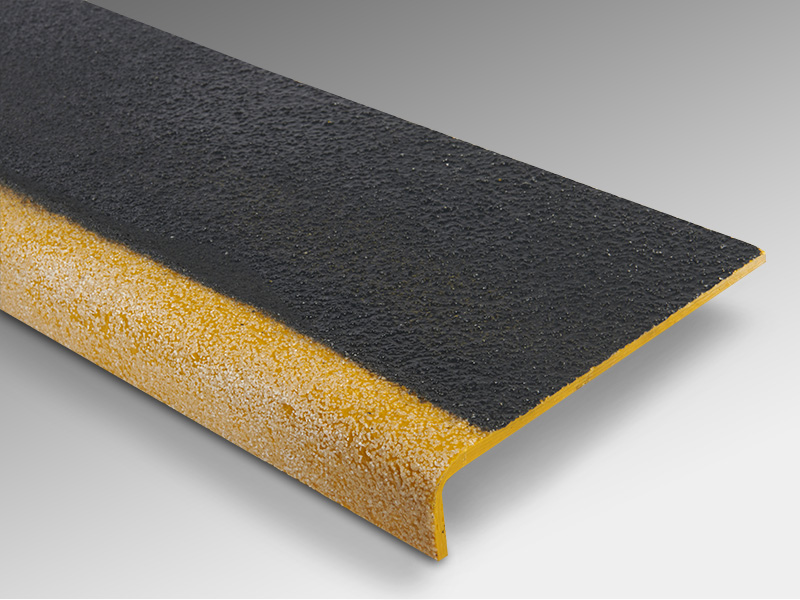

FRP stair covers are designed with functionality and safety in mind, incorporating the following features:

-

Surface antidérapante:

- The covers have a textured surface that provides superior grip even in wet, oily, or icy conditions.

- Meets OSHA and ANSI standards for slip resistance.

-

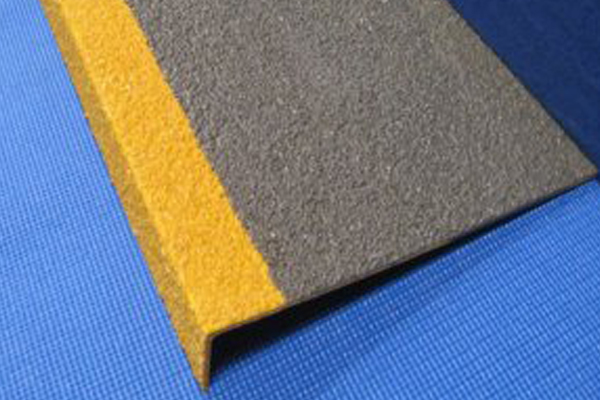

Full Stair Coverage:

- Covers both the tread and nosing (front edge) of the step, ensuring complete protection and safety.

- Rounded or square nosing options enhance durability and visual appeal.

-

Customizable Dimensions:

- Available in various widths, lengths, and thicknesses to accommodate different stair sizes and applications.

-

Résistance à la corrosion:

- Impervious to rust, rot, and corrosion, making them ideal for harsh environments like chemical plants or coastal areas.

-

Options de couleur:

- Offered in standard colors like yellow, gray, and black, as well as custom colors for aesthetic or safety purposes.

- Bright, contrasting nosing colors improve visibility and reduce trip hazards.

-

Facilité d'installation:

- Designed for quick and simple installation over existing stairs without the need for extensive construction or specialized tools.

3. Key Benefits

FRP stair covers provide numerous advantages over traditional materials such as wood, metal, or concrete:

-

Sécurité améliorée:

- The slip-resistant surface reduces the risk of slips and falls, even in hazardous conditions.

- Contrasting colors and nosing improve visibility for better stair navigation.

-

Durabilité:

- Withstands heavy traffic, harsh chemicals, and environmental stresses without cracking, warping, or wearing out.

- Retains its performance and appearance for decades with minimal maintenance.

-

Cost-Effectiveness:

- Extends the lifespan of existing staircases by reinforcing worn-out surfaces, eliminating the need for costly replacements.

- Low maintenance requirements reduce ongoing costs.

-

Lightweight and Versatile:

- Easier to transport and install compared to heavy metal or concrete alternatives.

- Suitable for indoor and outdoor applications in industrial, commercial, and residential settings.

-

Eco-Friendly:

- Long-lasting materials minimize waste and reduce environmental impact.

4. Applications

FRP stair covers are versatile and suitable for a wide range of applications:

- Installations industrielles: Provide safe footing in factories, refineries, and chemical plants where exposure to moisture, chemicals, and oils is common.

- Marine et Offshore: Perfect for docks, ships, and offshore platforms due to their excellent resistance to saltwater and humidity.

- Bâtiments commerciaux: Improve safety and aesthetics in office complexes, parking structures, and shopping malls.

- Infrastructures publiques: Enhance the durability and safety of stairs in railway stations, bridges, and pedestrian walkways.

- Résidentiel: Ideal for outdoor stairs, decks, and pool areas where slip resistance and durability are required.

5. Types of FRP Stair Covers

-

Standard FRP Stair Covers:

- Feature a gritted surface for reliable slip resistance.

- Available in various sizes and colors for general-purpose use.

-

Heavy-Duty Stair Covers:

- Designed for high-traffic and heavy-load environments, such as industrial plants or public infrastructure.

-

UV-Resistant Stair Covers:

- Engineered for outdoor use, with added UV inhibitors to prevent fading and degradation.

-

Fire-Resistant Stair Covers:

- Meet stringent fire safety regulations, making them ideal for applications where fire hazards are a concern.

-

Custom Stair Covers:

- Tailored to specific requirements, including unique dimensions, colors, or finishes.

6. Technical Specifications

- Épaisseur: Typically ranges from 3 mm (1/8 inch) to 8 mm (5/16 inch), depending on application needs.

- Dimensions: Standard sizes are available, with custom options to fit non-standard stair dimensions.

- Résistance au glissement: Coefficient of friction (COF) values generally exceed 0.65 for both wet and dry conditions.

- Temperature Range: Operates effectively in temperatures from -40°C to 120°C (-40°F to 248°F).

- Résistance chimique: Resistant to a wide range of chemicals, including acids, alkalis, and solvents.

- Capacité de chargement: Supports heavy foot traffic and complies with OSHA requirements.

7. Installation Process

FRP stair covers are designed for ease of installation, requiring minimal effort and tools:

-

Preparation:

- Clean and dry the existing stair surface.

- Remove loose debris, grease, or dirt to ensure proper adhesion.

-

Measurement and Cutting:

- Measure the stair dimensions and cut the FRP covers to size using a carbide or diamond-tipped blade.

-

Positionnement:

- Place the covers over the stairs, ensuring proper alignment with the nosing and edges.

-

Attachment:

- Secure the covers using adhesive, screws, or clips, depending on the application.

- Apply additional sealant along the edges for enhanced durability and appearance.

-

Finition:

- Allow adhesives to cure before use and verify the stability of the installation.

8. Maintenance Guidelines

FRP stair covers are designed for minimal maintenance, but periodic care ensures optimal performance:

- Regular Cleaning: Use a mild detergent and water to remove dirt, grease, or stains. Avoid abrasive cleaners that may damage the gritted surface.

- Inspection: Periodically check for signs of wear or damage, such as loose fasteners or surface degradation.

- Réparations: Replace worn-out grit coatings or damaged covers as needed.

- UV Coating: Reapply protective UV coatings periodically for outdoor applications.

9. Compliance and Certifications

High-quality FRP stair covers meet industry standards for safety, performance, and environmental responsibility:

- OSHA (Occupational Safety and Health Administration): Complies with workplace safety standards for slip resistance and load capacity.

- ANSI (American National Standards Institute): Adheres to slip resistance and durability specifications.

- ASTM Standards: Covers performance metrics like fire resistance, chemical resistance, and structural integrity.

- ISO 9001: Ensures quality management during manufacturing.

10. Frequently Asked Questions (FAQs)

-

What is the lifespan of FRP stair covers?

- With proper care, FRP stair covers can last 20-30 years or more.

-

Are FRP stair covers suitable for outdoor use?

- Yes, they are resistant to UV rays, moisture, and extreme temperatures.

-

Can they be customized?

- Absolutely, FRP stair covers can be tailored to fit unique dimensions, colors, and designs.

-

How do they compare to metal covers?

- FRP covers are lightweight, corrosion-proof, and require less maintenance than metal alternatives.

-

What safety standards do they meet?

- FRP stair covers comply with OSHA, ANSI, and ASTM standards for slip resistance, fire safety, and structural performance.

Conclusion

FRP stair covers are a practical and cost-effective solution for enhancing the safety and durability of staircases in various settings. Their non-slip surface, resistance to environmental stresses, and ease of installation make them an ideal choice for industrial, commercial, and residential applications. With a wide range of customizable options and compliance with international safety standards, FRP stair covers are the ultimate upgrade for worn-out or unsafe stairs.

Covered FRP Stair Covers with High Traction Surface

Série :

Fiberglass Stair Treads >application

FAQ

Autres produits connexes