How to order pultruded frp grating

Ordering pultruded FRP grating involves several steps to ensure you get the right product for your specific needs. Here's a guide to help you:

How to order pultruded frp grating

1. Understand Your Requirements

- Application: Identify where the grating will be used (e.g., offshore platforms, chemical plants, walkways, or stair treads).

- Capacité de chargement: Determine the load the grating must bear (pedestrian, light vehicle, or heavy equipment).

- Environmental Conditions: Consider factors like chemical exposure, UV resistance, and fire retardancy.

- Standards and Compliance: Check if you need gratings that comply with specific standards (e.g., ASTM, OSHA).

2. Choose the Right Specifications

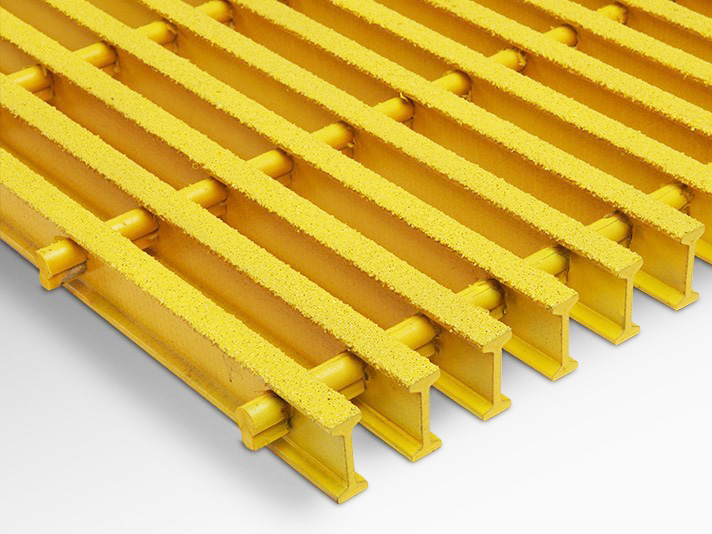

- Grating Type: Decide on pultruded grating over molded grating for higher strength and stiffness.

- Bar Spacing: Select the spacing based on the application's load and ventilation needs.

- Épaisseur: Common thicknesses include 25 mm (1 inch), 38 mm (1.5 inches), and 50 mm (2 inches).

- Taille du panneau: Measure the required panel dimensions to avoid unnecessary cutting and wastage.

- Options de surface: Choose between plain, anti-slip, or gritted surfaces for safety.

3. Select the Resin Type

The choice of resin depends on environmental conditions:

- Polyester (Isophthalic): Good for general applications with moderate chemical exposure.

- Ester vinylique: Ideal for highly corrosive environments, such as those exposed to strong acids or alkalis.

- Phénolique: Fire-resistant and suitable for areas with stringent safety requirements.

- Orthophthalic Polyester: Economical choice for less demanding environments.

4. Additional Features

- Couleur: Choose standard colors like gray, yellow, or green, or request custom colors.

- Accessories: Decide if you need hold-down clips, mounting brackets, or special coatings.

- Personnalisation: Some manufacturers offer tailored panel shapes, sizes, or cutouts for specific installations.

5. Identify Reliable Suppliers

- Research Suppliers: Look for reputable manufacturers or distributors specializing in FRP gratings.

- Request Samples: Some suppliers provide samples to evaluate the quality before making bulk orders.

- Check Certifications: Ensure the supplier adheres to international quality standards like ISO 9001.

6. Place Your Order

- Submit a Request for Quote (RFQ): Provide detailed specifications, including quantities, dimensions, and delivery location.

- Discuss Lead Times: Confirm production and delivery timelines, especially for custom orders.

- Review the Quotation: Check for additional costs such as shipping, cutting, or customization.

- Finalize the Order: Provide a purchase order (PO) after agreeing to the terms and conditions.

7. Delivery and Installation

- Inspect the Shipment: Verify that the delivered gratings match the ordered specifications.

- Plan Installation: Follow the supplier’s guidelines for cutting, fastening, and installing the grating.

8. After-Sales Support

- garantie: Ensure the product comes with a warranty for defects or performance issues.

- Maintenance Tips: Request guidance on cleaning and maintaining the grating for extended life.