SMC (Sheet Molding Compound) fiberglass grating pedestals are critical components in modern infrastructure and industrial applications, designed to support and elevate fiberglass grating systems. These pedestals provide a stable, durable, and corrosion-resistant foundation that is essential for a wide range of industries, including construction, manufacturing, marine, and chemical processing. They ensure that the grating is properly aligned, secure, and functional, even in challenging environmental conditions. This article explores SMC fiberglass grating pedestals in detail, covering their material properties, advantages, applications, and installation process, as well as comparing them to other alternatives.

1. Introduction to SMC Fiberglass Grating Pedestals

Fiberglass grating systems are used extensively in environments where traditional metal or wooden grating would deteriorate due to harsh conditions such as exposure to chemicals, extreme temperatures, or constant foot traffic. These grating systems are mounted on pedestals that ensure they are raised to the correct height and securely supported, allowing for effective drainage, airflow, and easy maintenance access.

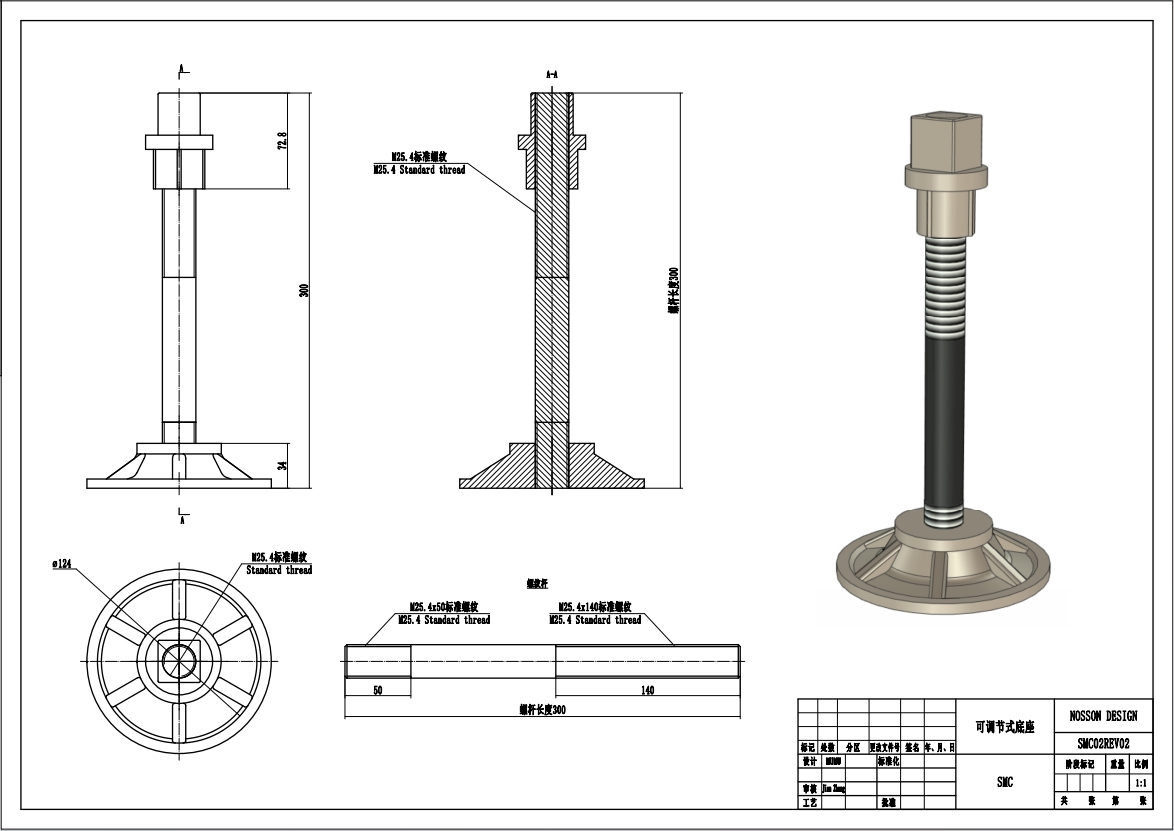

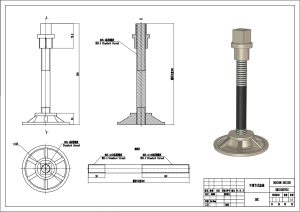

SMC fiberglass grating pedestals specifically refer to support structures made from Sheet Molding Compound, a composite material that combines fiberglass reinforcement with resin to create a product that is both lightweight and exceptionally strong. This composite material is molded under high pressure and heat, which allows for precise control over its shape and mechanical properties, making it ideal for demanding applications.

2. Material Properties of SMC Fiberglass Pedestals

SMC fiberglass grating pedestals are made from a specific form of fiberglass-reinforced composite material, which combines fiberglass with a resin system. The key properties of this material make it highly advantageous in various industrial and commercial applications:

-

Résistance à la corrosion: One of the standout features of SMC fiberglass is its outstanding resistance to corrosion. Unlike metal pedestals, which can rust and degrade over time when exposed to moisture, chemicals, and other corrosive agents, SMC fiberglass remains intact and structurally sound, even in environments like sewage plants, chemical processing units, and marine applications. This makes fiberglass pedestals ideal for use in coastal areas, industrial plants, and offshore platforms where corrosion is a significant concern.

-

Rapport résistance/poids élevé: SMC fiberglass is both lightweight and strong. This characteristic makes the pedestals easy to handle, transport, and install without compromising on their ability to bear heavy loads. The high strength of the composite material ensures that the pedestals can support the weight of the grating system, equipment, and personnel without sagging or failing.

-

Electrical Insulation: Fiberglass is a non-conductive material, which provides electrical insulation. This is a critical property in environments where there is a risk of electrical exposure or where the grating system must meet electrical safety standards, such as in power plants, data centers, or chemical processing facilities.

-

Thermal Stability: Fiberglass materials exhibit high thermal stability, making SMC fiberglass grating pedestals suitable for environments with temperature extremes. Whether exposed to hot or cold conditions, these pedestals maintain their integrity and do not warp, degrade, or lose their mechanical properties.

-

Dimensional Stability: The molding process used to create SMC fiberglass ensures that the material maintains its shape and dimensional integrity over time, even under continuous load. This makes the pedestals reliable and stable for long-term use.

-

Faible entretien: Unlike wood or metal, SMC fiberglass is resistant to environmental factors like moisture, insects, and UV radiation, requiring minimal maintenance. This durability translates to reduced downtime, fewer repairs, and lower long-term operational costs.

SMC Fiberglass Grating Pedestals

3. Advantages of SMC Fiberglass Grating Pedestals

The use of SMC fiberglass grating pedestals offers numerous advantages over traditional support systems made of metal, concrete, or wood. These benefits include:

a. Résistance à la corrosion

SMC fiberglass grating pedestals are highly resistant to rust, corrosion, and chemical attack. In industries such as oil and gas, marine construction, and wastewater treatment, where exposure to harsh chemicals and seawater is common, this resistance is critical. Traditional metal pedestals can suffer from rust and structural degradation when exposed to chemicals, moisture, or saline environments, leading to expensive repairs and replacements. The fiberglass-based material ensures that SMC pedestals last longer and maintain their structural integrity.

b. Lightweight and Strong

One of the key benefits of SMC fiberglass is its combination of lightness and strength. Despite being much lighter than steel or concrete alternatives, SMC fiberglass pedestals can support heavy loads. This lightweight nature allows for easier handling, transportation, and installation, reducing labor costs and installation time. It also reduces the overall weight of the structure, which is especially important in elevated platforms, walkways, or in any installation where load-bearing capacity is a priority.

c. Versatility in Applications

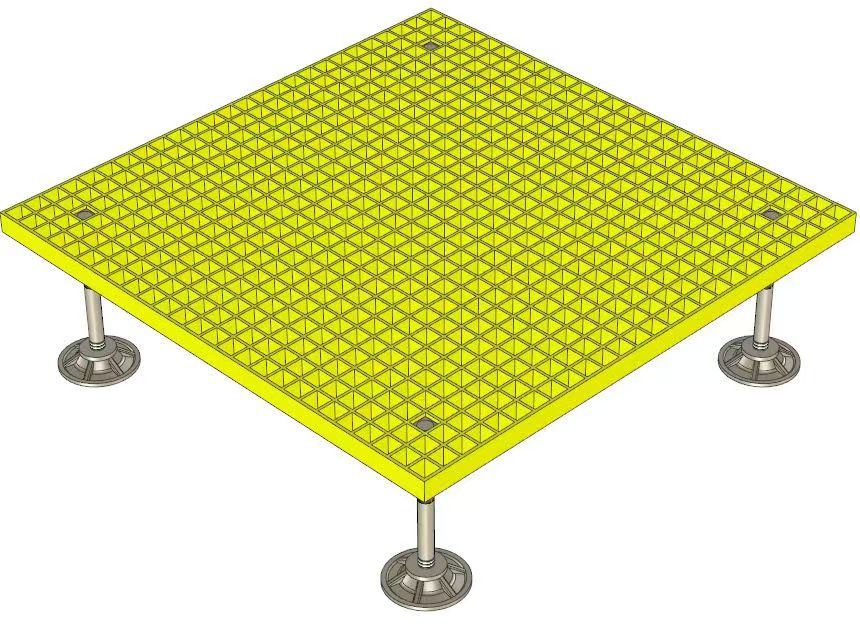

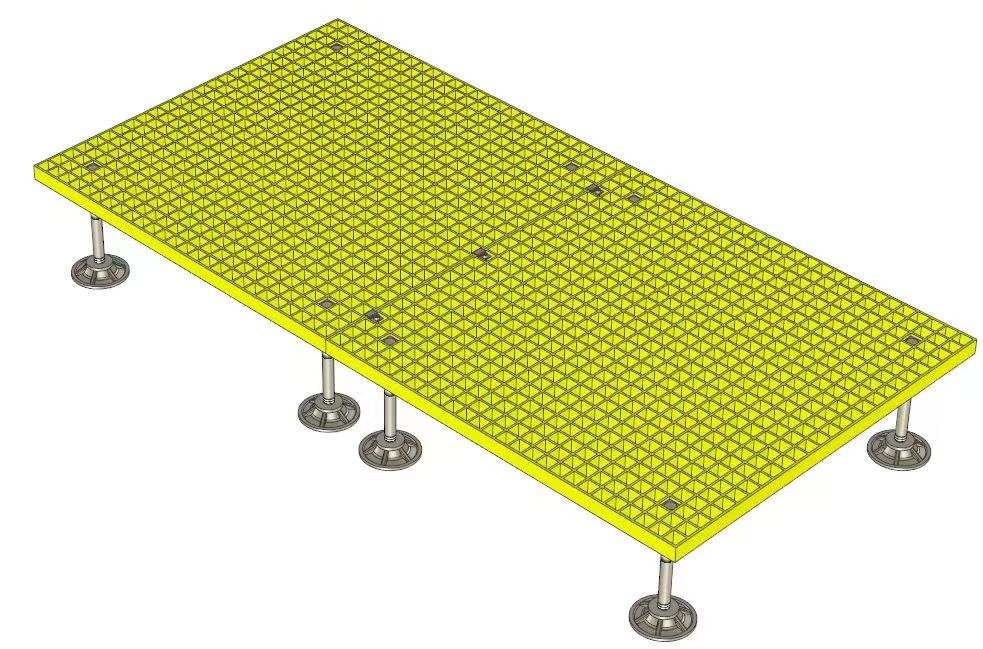

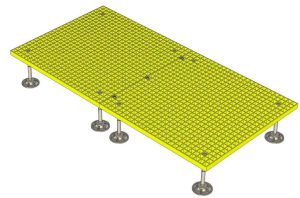

SMC fiberglass grating pedestals are used in a wide range of applications across different industries. They can support elevated walkways, drainage grating, safety platforms, and even industrial mezzanines. The ability to adjust the height and create a stable base for grating makes these pedestals versatile in settings such as:

- Industrial and Commercial Applications: SMC pedestals provide support for grating in factories, warehouses, and commercial buildings, allowing for proper ventilation and easy access to pipes and electrical systems.

- Marine and Offshore Applications: Offshore platforms and marine installations benefit from the corrosion-resistant properties of fiberglass, ensuring long-lasting performance in salty, wet conditions.

- Stations de traitement des eaux usées: The ability to withstand exposure to chemicals and moisture makes these pedestals perfect for use in wastewater facilities, where the environment is highly corrosive.

- Centrales électriques: SMC fiberglass pedestals are also suitable for supporting grating in power plants, where electrical insulation is critical for safety.

d. Reduced Long-Term Costs

Because of their durability, SMC fiberglass grating pedestals require minimal maintenance over their lifetime. In contrast to traditional metal supports that may need frequent maintenance or replacement due to corrosion, fiberglass pedestals reduce the total cost of ownership. They are also easy to clean, ensuring that they remain functional and visually appealing for years without the need for constant upkeep.

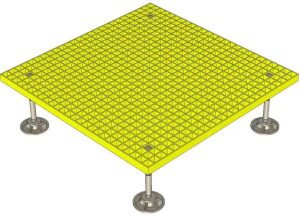

e. Safety and Stability

The non-slip surface of fiberglass grating combined with the sturdy support from the pedestals provides a safe working environment. The combination of fiberglass and pedestal systems allows workers to move safely in high-risk areas, even in wet or hazardous environments. The adjustable height of the pedestals allows for a precise and stable structure that prevents the grating from shifting or becoming misaligned, ensuring long-term safety.

SMC Fiberglass Grating Pedestals

4. Applications of SMC Fiberglass Grating Pedestals

SMC fiberglass grating pedestals are widely used in industries where durability, safety, and corrosion resistance are paramount. Some common applications include:

a. Passerelles et plates-formes

Fiberglass grating systems are commonly used to create walkways and access platforms in industrial and commercial settings. SMC fiberglass pedestals provide stable and reliable support for the grating panels, ensuring that they remain secure even in high-traffic areas. These systems are often used in warehouses, chemical plants, offshore oil rigs, and other environments where elevated platforms are needed for workers to move safely and efficiently.

b. Marine and Coastal Structures

In coastal or offshore installations, the corrosive effects of saltwater can cause severe damage to metal structures. SMC fiberglass pedestals, however, offer an ideal solution by resisting corrosion from seawater, making them suitable for supporting grating in piers, docks, offshore oil platforms, and marine equipment walkways.

c. Wastewater Treatment Facilities

In wastewater treatment plants, where chemicals and moisture are abundant, the corrosion-resistant nature of SMC fiberglass grating pedestals helps maintain the integrity of the grating systems. The pedestals raise the grating above ground level, facilitating drainage and reducing the accumulation of debris.

d. Power and Utility Plants

SMC fiberglass grating pedestals are used in power and utility plants, where the potential for electrical hazards is significant. Their non-conductive properties ensure that the grating remains electrically safe for personnel while providing a stable platform for maintenance, access to equipment, and support for utilities.

5. Installation and Maintenance of SMC Fiberglass Grating Pedestals

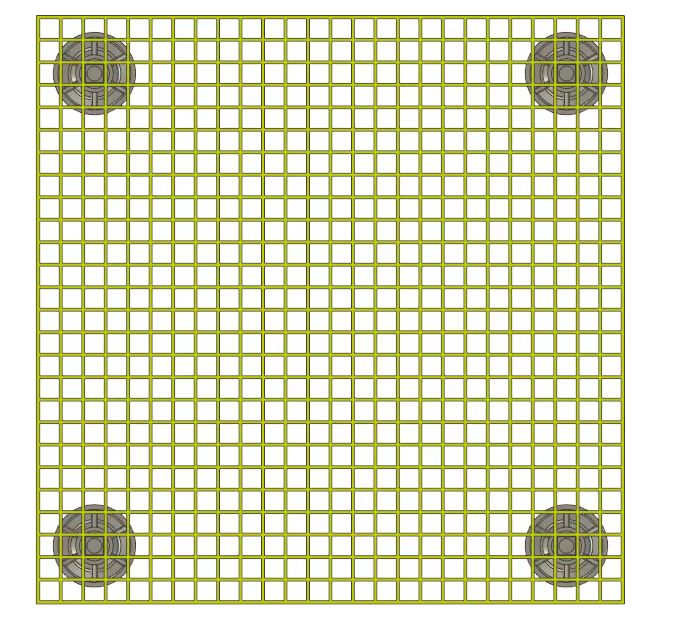

The installation of SMC fiberglass grating pedestals is straightforward. Pedestals are typically adjustable, allowing for precise height adjustments to align with the grating system. Installation involves securing the pedestals to the base surface, followed by placing the grating panels on top. The adjustable nature of the pedestals ensures that the grating remains level and stable.

Once installed, SMC fiberglass grating pedestals require minimal maintenance. Regular cleaning and inspections are recommended to ensure that the grating and pedestals remain in optimal condition. Due to the non-corrosive nature of the fiberglass material, the need for repairs or replacements is significantly reduced compared to metal-based systems.

6. Conclusion

SMC fiberglass grating pedestals represent a highly efficient, durable, and cost-effective solution for supporting fiberglass grating systems in various industrial and commercial applications. Their corrosion resistance, high strength-to-weight ratio, and versatility make them ideal for use in environments where traditional materials would fail. Whether used in wastewater treatment plants, marine structures, or industrial walkways, SMC fiberglass pedestals provide a safe, reliable, and long-lasting foundation for grating systems, ensuring that they perform optimally in even the harshest conditions.