Fiberglass reinforced plastic grating (also known as FRP grating, glass reinforced plastic grating or fiberglass grating) is a composite material manufactured by combining a matrix of resin and fiberglass. FRP grating is a structural product that can be weight-bearing between spans.

Product performance introduction

The Fiberglass Cover Plate is a high-performance solution crafted from fiberglass reinforced plastic (FRP), designed to offer a lightweight, strong, and corrosion-resistant alternative to traditional materials. Suitable for industrial, commercial, and outdoor applications, this cover plate is ideal for harsh environments where long-term durability, safety, and minimal maintenance are required.

Detailed Product Features:

-

High-Strength Material

- Composition: Made from fiberglass reinforced plastic (FRP) and engineered resins.

- Benefits: High load-bearing strength, capable of supporting pedestrian and light vehicular traffic, depending on thickness.

-

Corrosion Resistance

- Environment: Resistant to chemicals, oils, saltwater, and moisture, making it ideal for marine, wastewater, and chemical environments.

- Benefit: Outlasts steel or wood alternatives, especially in corrosive or wet settings.

-

Lightweight Design

- Weight: 25–50% lighter than metal plates, simplifying handling and installation.

- Benefit: Reduced transportation costs and easier manual handling for workers.

-

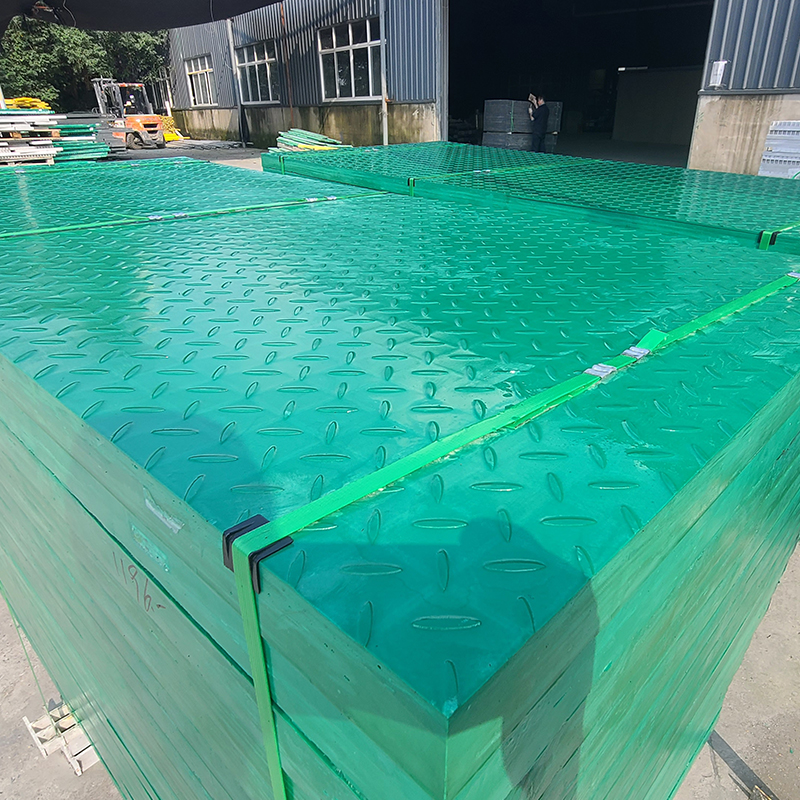

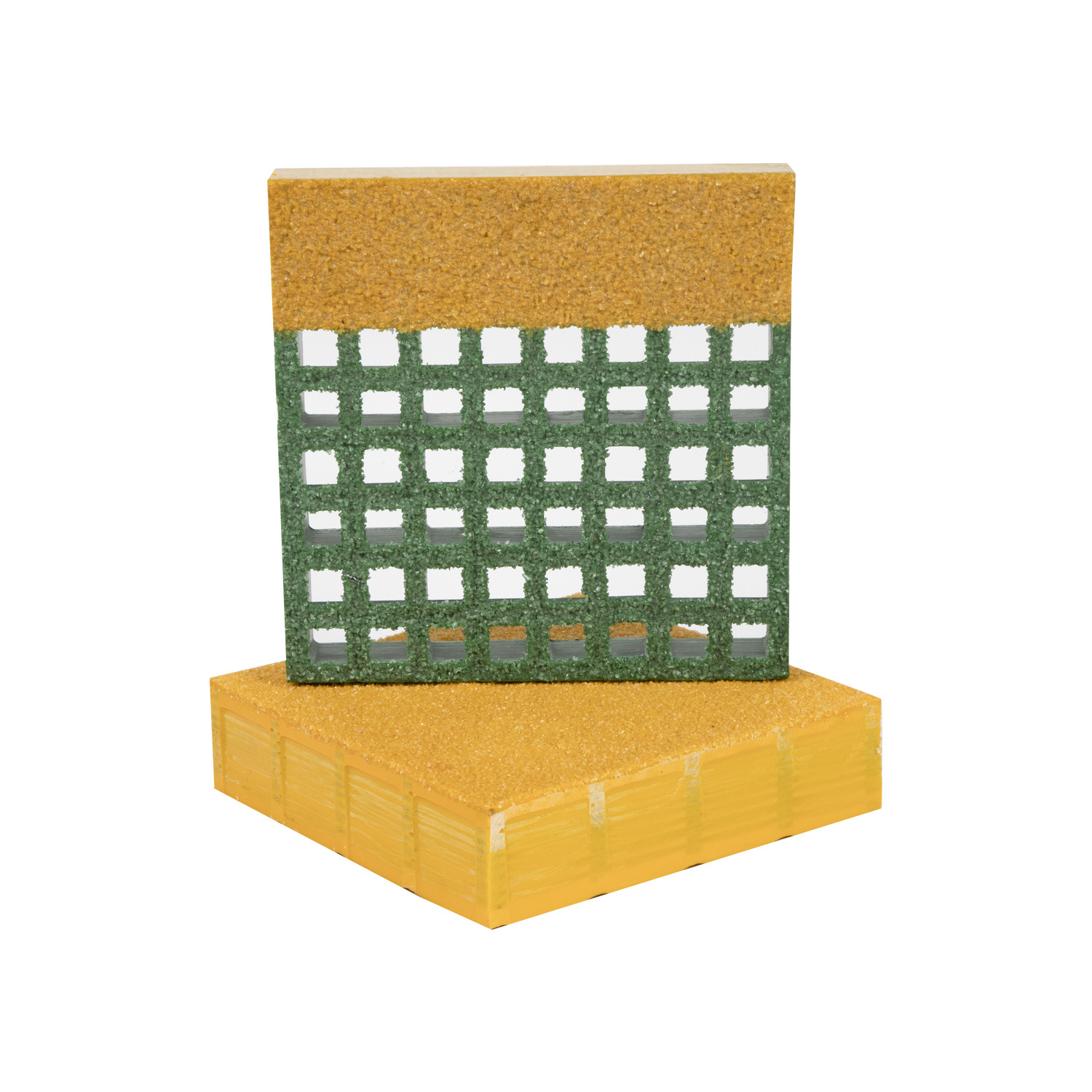

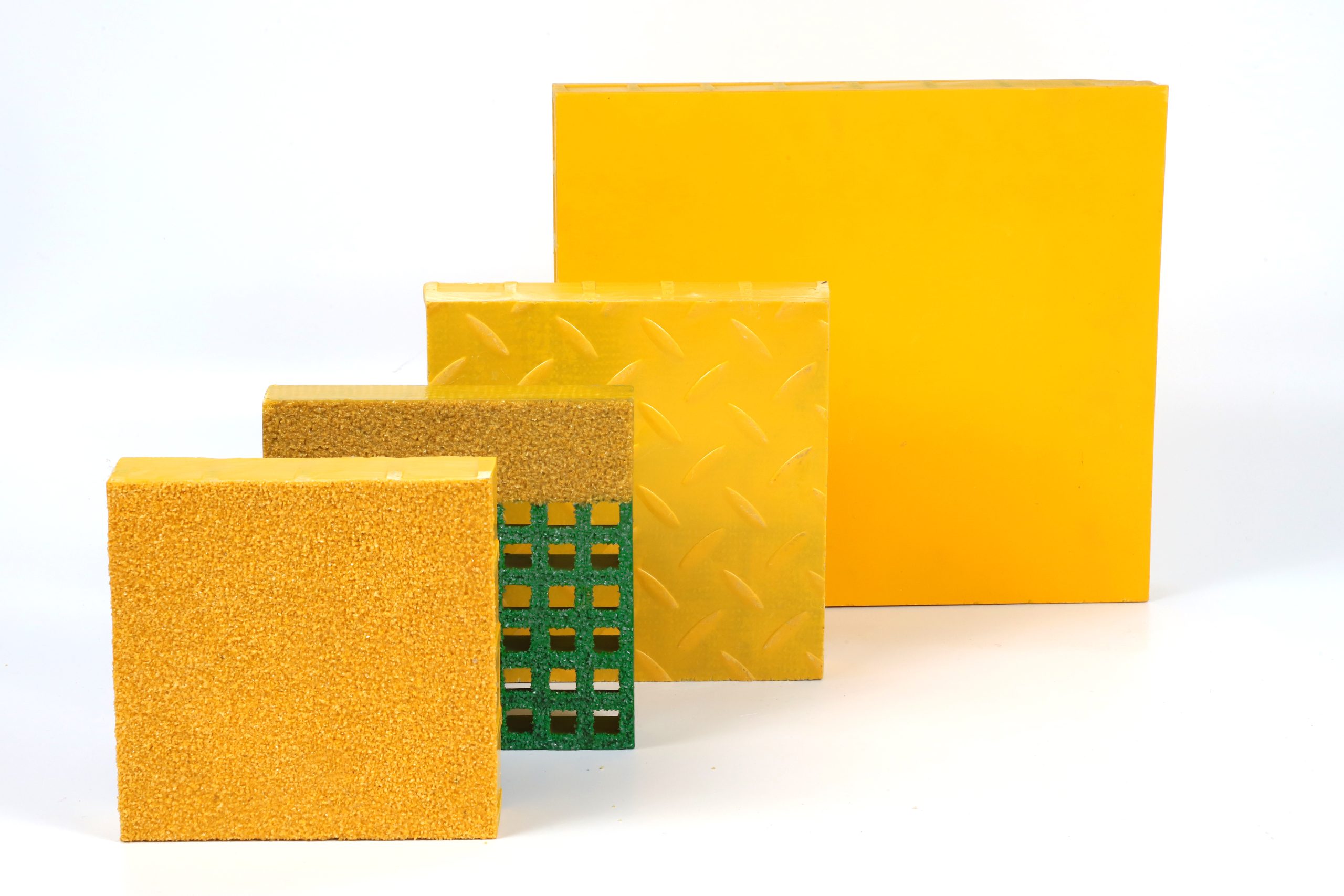

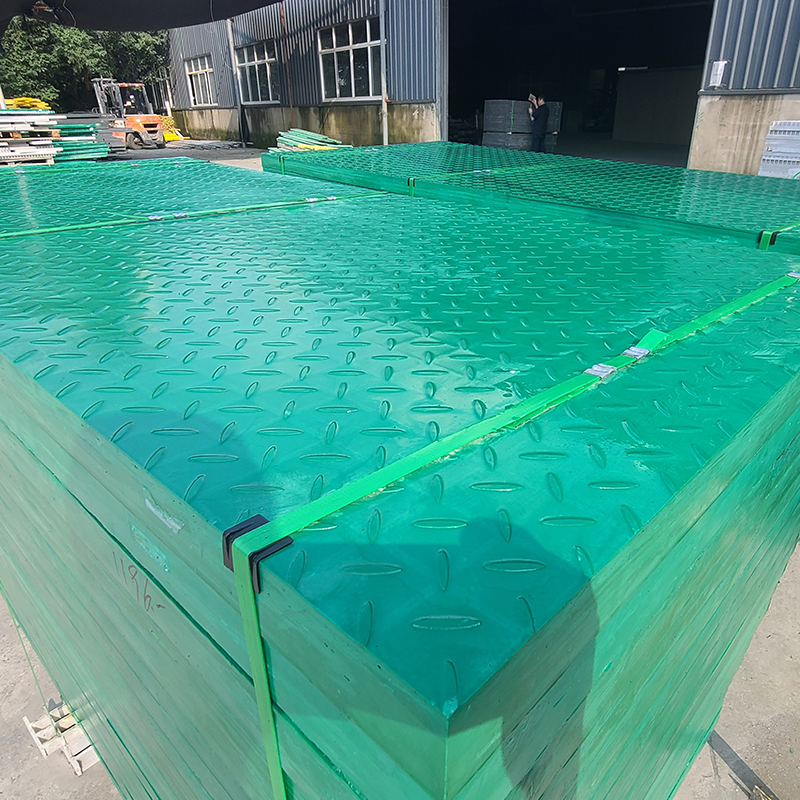

Anti-Slip Surface

- Surface Options: Available with gritted textures, patterned surfaces, or smooth finishes to meet specific traction needs.

- Safety Compliance: Complies with slip-resistance standards, reducing fall risks in wet or oily conditions.

-

UV Stabilization

- UV-Resistant Resin: Protects the cover from sun damage and fading in outdoor environments.

- Long-Term Durability: Suitable for long-term exposure in both sunny and shaded areas.

-

Fire Resistance

- Fire-Retardant Grades: Available in fire-resistant resins meeting Class 1 and Class 2 fire ratings.

- Safety: Provides enhanced safety in facilities with flammable materials or high fire-risk areas.

-

Non-Conductive

- Electric Safety: Fiberglass is non-conductive, making it safe for use near electrical equipment and cables.

- Ideal for: Industrial and electrical settings where accidental conductivity could pose risks.

-

Customizable Options

- Dimensions: Available in standard and custom sizes to fit trenches, ducts, and walkways.

- Color Options: Standard colors like gray, yellow, green, or custom colors for visibility or branding.

- Thickness: Common options range from 5 mm to 50 mm, adaptable to load and durability requirements.

- Additional Coatings: Anti-graffiti, anti-bacterial, and additional UV coatings available upon request.

Technical Specifications:

-

Standard Dimensions:

- Thickness: 5 mm, 10 mm, 15 mm, and custom thicknesses available.

- Width & Length: Standard sizes and customizable dimensions based on specific project requirements.

-

Load Capacity:

- Pedestrian Load: Typically 1,000–2,000 lbs, depending on plate thickness.

- Vehicle Load: Heavy-duty options available for light vehicular load requirements.

-

Temperature Resistance:

- Range: -30°C to +120°C (-22°F to +248°F), suitable for extreme temperature environments.

-

Weight:

- 25–30% the weight of equivalent steel plates, easing installation and reducing labor costs.

Applications:

-

Industrial Facilities

- Trench and duct covers, flooring for chemical processing plants, and power plants where chemical exposure or electricity is present.

-

Marine & Coastal

- Ideal for docks, piers, and ports that face frequent exposure to saltwater and moisture.

-

Water & Wastewater Treatment

- Trench covers and flooring, where constant moisture and chemical resistance are needed.

-

Transportation and Public Infrastructure

- Used in transit stations, airports, and bridges for trench covering and safe walkways.

-

Commercial Spaces

- Slip-resistant flooring or trench covers in shopping centers, public walkways, and ramps.

-

Outdoor Applications

- Long-lasting cover solutions for public parks, outdoor platforms, and recreational areas.

Benefits:

-

Long-Lasting Performance

- Provides extended lifespan compared to metal or concrete, especially in challenging environments.

-

Low Maintenance

- Requires no painting or additional corrosion treatment; only periodic cleaning and inspection.

-

Enhanced Safety

- Anti-slip surface and non-conductive properties create a safer work environment in high-risk areas.

-

Cost-Effective

- Higher initial cost offset by reduced maintenance and replacement expenses, delivering value over time.

Installation:

- Ease of Installation

- Modular and lightweight design enables rapid installation with minimal labor requirements.

- Mounting Options

- Can be bolted or secured using brackets, clamps, or other anchoring systems.

- Cut-to-Fit Options

- Plates can be cut to fit specific requirements onsite or custom-sized during manufacturing.

Maintenance:

- Cleaning

- Routine cleaning with soap and water; resistant to most stains and surface corrosion.

- Inspection

- Recommended periodic inspection, especially in high-traffic or chemically exposed areas.

Warranty:

- Standard Warranty: Generally 5-10 years against manufacturing defects, with extended warranties available for demanding applications.

Compliance:

- Slip-Resistance Standards: Meets OSHA standards for slip resistance, with certification available.

- Fire Resistance Standards: Complies with Class 1 and Class 2 fire ratings where applicable.

FRP cover plate fiberglass trench cover

Series :

Main Products >application

Chemical industry, paper industry, power plant, sewage treatment plant, offshore drilling platform, food processing plants melting.Refineries, mines, salt farms, nuclear power plants.battery plants and so on. Can be used as: pedestrian walkway, bridge plank, work lndustrial floor, operating platform, trench cover, pallet, guardrail, fence, shelf, isolation belt, green walkway, Floor step,etc.

Brand name :

TFcomposite

Product name :

Fiberglass Cover Plate

Technique :

Molded

Material :

Unsaturated polyester resin and glass fiber roving

MOQ :

50pcs

FAQ

Q :

Are you a factory that produces FRP molded grating?

A :

Yes, we are a professional manufacturer of FRP gratings, we have covers an area of nearly 15,000 square meters, has nearly 120 employees, equipped more than 100 sets of standard grating molds, 15 automatic pultrusion lines.

Q :

How to choose if there is a requirement for the load bearing of the FRP grating?

A :

It depends on the application where you buy the grating, whether it is a walkway or a passing vehicle.

Q :

We are a decoration company, can we buy your FRP grating as decorations?

A :

Yes, our colors can be customized according to customer needs, we can make all the colors on the Raul color card.

Q :

Do you guarantee after-sales service when purchasing your FRP grating?

A :

Yes, we can guarantee two years of after-sales.

Other related products