Product performance introduction

1. Introduction to Galvanized Steel Grating

Galvanized steel grating is a highly durable and corrosion-resistant material commonly used in industrial, commercial, and architectural applications. It is made by welding, pressing, or riveting steel bars together, followed by a hot-dip galvanizing process to protect against rust and environmental damage.

2. Specifications of Galvanized Steel Grating

2.1 Types of Galvanized Steel Grating

Galvanized steel grating is classified based on manufacturing processes and load-bearing capacity:

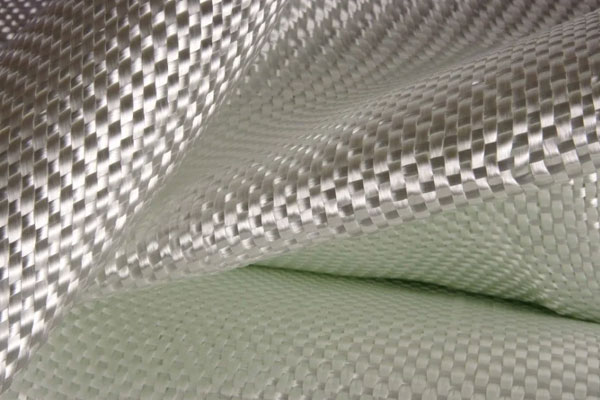

1. Welded Steel Grating

Welded steel grating is the most common type, manufactured by welding bearing bars and crossbars together at high temperatures. It is strong, durable, and cost-effective.

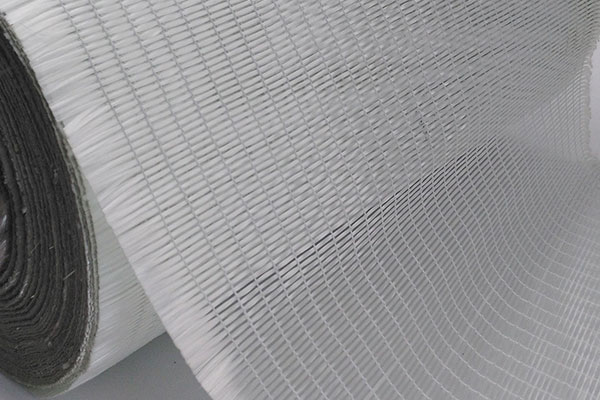

Example Image: Welded Steel Grating

2. Press-Locked Steel Grating

Press-locked grating is produced by mechanically pressing crossbars into bearing bars under high pressure. It provides a clean, smooth surface and is often used in architectural applications.

Example Image: Press-Locked Steel Grating

3. Swage-Locked Steel Grating

Swage-locked grating is made by interlocking crossbars and bearing bars through a swaging process, which enhances strength and rigidity. It is widely used in flooring and industrial platforms.

Example Image: Swage-Locked Steel Grating

4. Riveted Steel Grating

Riveted grating features riveted connections between the crossbars and bearing bars, offering superior load-bearing capacity. It is suitable for heavy-duty applications.

Example Image: Riveted Steel Grating

2.2 Material Composition

-

Bearing Bars: Made from carbon steel, stainless steel, or aluminum, with thickness ranging from 2mm to 10mm.

-

Cross Bars: Twisted square rods or round bars made of similar metals.

-

Galvanization Standard: Hot-dip galvanization follows ASTM A123, EN ISO 1461, or equivalent standards, ensuring a coating thickness of 70 microns or more.

2.3 Surface Treatments

-

Hot-Dip Galvanized: Best for corrosion resistance.

-

Painted or Powder-Coated: Used for color coding or aesthetic appeal.

-

Mill Finish: Untreated raw steel for specific applications.

3. Dimensions and Configurations

3.1 Standard Panel Sizes

-

Width: 600mm, 800mm, 1000mm, or custom sizes.

-

Length: 1000mm, 1200mm, 1500mm, 2000mm, or up to 3000mm.

-

Custom Sizes: Available upon request.

3.2 Bearing Bar Spacing

-

Common Spacings: 19mm, 30mm, 40mm.

-

Heavy-Duty Options: 50mm or more for vehicular loads.

3.3 Cross Bar Spacing

-

Typical Spacings: 38mm, 50mm, or customized.

3.4 Load Capacities

-

Load-bearing capacities range from 500 kg/m² to 5000 kg/m² based on bar depth and spacing.

4. Performance Characteristics

4.1 Corrosion Resistance

Hot-dip galvanization protects the grating from rust and harsh environmental conditions, making it ideal for outdoor and marine applications.

4.2 Strength and Durability

-

Welded steel grating provides excellent mechanical strength.

-

Heavy-duty options support vehicle loads, including forklifts and trucks.

4.3 Slip Resistance

-

Serrated steel grating enhances grip, making it suitable for slippery environments.

4.4 Fire Resistance

-

Steel grating is non-combustible, making it an ideal choice for industrial safety.

5. Applications of Galvanized Steel Grating

-

Industrial Flooring: Used in factories and power plants.

-

Walkways & Catwalks: Found in construction sites and refineries.

-

Drainage Covers: Ideal for stormwater management.

-

Stair Treads: Provides additional safety with anti-slip features.

-

Security Barriers: Used in fences and enclosures.

Galvanized Steel Grating

Series :

Proxy Products >application

Industrial Flooring: Used in factories and power plants. Walkways & Catwalks: Found in construction sites and refineries. Drainage Covers: Ideal for stormwater management. Stair Treads: Provides additional safety with anti-slip features. Security Barriers: Used in fences and enclosures.

FAQ

Other related products