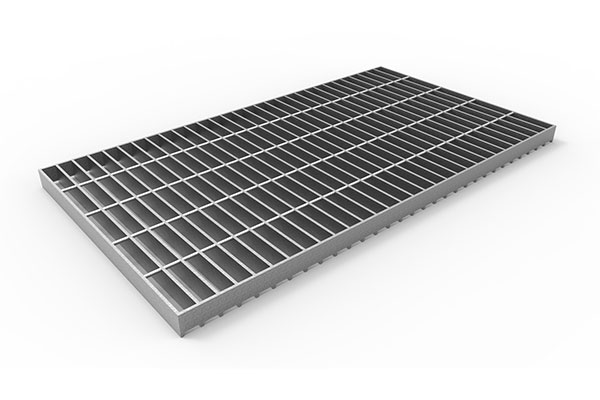

A Galvanized Steel Grating Trench Cover is an industrial-grade steel product specifically designed to provide a durable, load-bearing, and corrosion-resistant cover for trenches, cable ducts, drainage channels, utility corridors, and maintenance pits. Made from carbon steel or stainless steel and protected by hot-dip galvanizing, this product is essential in a wide variety of infrastructure, civil, industrial, and commercial applications.

Pengenalan kinerja produk

Galvanized steel trench grates are engineered to support heavy vehicular or pedestrian traffic while allowing for adequate drainage and ventilation. They are a safe and maintenance-free solution for long-term use in harsh environments, making them an industry standard in high-demand sectors like construction, mining, petrochemicals, transportation, and public utilities.

2. Technical Data Sheet (TDS)

| Properti | Spesifikasi |

|---|---|

| Bahan | Low carbon steel (Q235), stainless steel (304/316 optional) |

| Permukaan Akhir | Hot-dip galvanized (as per ASTM A123 / ISO 1461) |

| Galvanizing Thickness | ≥ 70μm (standard), optional up to 120μm |

| Grating Type | Welded press-locked or swage-locked steel bar grating |

| Bar Profile | Flat bar (standard), I-bar, or serrated flat bar |

| Load Bar Sizes | 20x3 mm to 65x5 mm (customizable based on load requirement) |

| Bar Pitch (spacing) | 30 mm, 40 mm (typical), custom pitch available |

| Cross Bar Pitch | 50 mm or 100 mm |

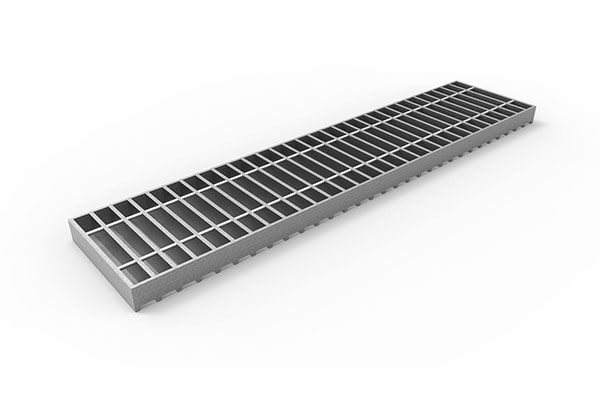

| Cover Width | 150 mm to 1000 mm+ (customizable) |

| Cover Length | Typically 1000 mm or modular |

| Load Bearing Capacity | Light (Class A15) to heavy duty (Class F900), per EN 124 or AASHTO |

| Deflection Tolerance | ≤ 1/200 of the span |

| Tolerance Standard | ISO 2768-1 (Fine/Medium) |

| Coating Life Expectancy | 30–50 years in outdoor conditions |

| Standard Compliance | ISO 9001, EN ISO 1461, ANSI/NAAMM MBG531, BS 4592 |

3. Features and Benefits

✅ High Load Capacity

Galvanized trench covers are designed to handle a wide range of loads, from pedestrian zones to areas exposed to forklifts, trucks, and even aircraft. The structural design and load bar selection ensure optimal strength-to-weight ratio.

✅ Tahan korosi

The hot-dip galvanization process forms a protective zinc coating that resists corrosion from water, chemicals, salts, and harsh weather, extending the product's lifespan and reducing maintenance.

✅ Drainage and Ventilation

Open grating structure allows rainwater, industrial liquids, and other fluids to flow freely into trenches while also allowing ventilation in cable ducts and service channels.

✅ Anti-Slip Options

Serrated surface bars are available to increase traction, minimizing the risk of slips and falls in wet or oily environments—ideal for safety-critical applications.

✅ Custom Fit and Modular Design

Modular trench covers can be customized in shape, size, and strength to fit specific trench dimensions, ensuring an efficient, safe, and aesthetic installation.

✅ Easy Installation and Maintenance

Lightweight yet strong design simplifies handling, installation, and removal. The modular nature allows easy access to underlying utilities without needing to dismantle the entire system.

✅ Fire and Impact Resistant

Steel grating offers natural fire resistance and superior impact strength compared to plastic, fiberglass, or concrete alternatives.

4. Common Types of Trench Grating Covers

a. Open Grating Trench Cover

-

Standard grating design with open slots.

-

Best for drainage and ventilation applications.

-

Common in roads, pavements, manufacturing, and airports.

b. Checkered Plate Covered Grating

-

Steel grating covered with a solid checkered or diamond plate.

-

Used in areas where complete coverage is required to prevent dirt or debris from entering the trench.

c. Lockable Grating Cover

-

Incorporates hinges or locking mechanisms.

-

Suitable for utility zones, telecom lines, or electrical ducts where security is a concern.

d. Recessed Grating Covers

-

Designed to be infilled with concrete, pavers, or tiles.

-

Used in architectural or aesthetic applications to blend into pavements.

5. Applications

Galvanized steel trench covers are widely used in:

-

Urban infrastructure: Roadsides, pedestrian walkways, highway drainage

-

Industrial facilities: Factories, warehouses, chemical plants

-

Power & energy sectors: Cable tray covers in substations, power plants

-

Water treatment plants: Channel and basin covers

-

Airports and ports: Runoff drainage and maintenance access

-

Parking lots and garages: Heavy-duty vehicular trench drainage

-

Commercial buildings: Landscaping, fountains, and garden drainage

6. Standards and Classifications

The trench cover system is classified by load-bearing capacity based on EN 124:

| Load Class | Kapasitas beban | Aplikasi Khas |

|---|---|---|

| A15 | 15 kN | Footways, cycling paths |

| B125 | 125 kN | Car parks, pedestrian zones |

| C250 | 250 kN | Light traffic, curbside roads |

| D400 | 400 kN | Main roads, industrial vehicle zones |

| E600 | 600 kN | Docks, warehouses, logistics areas |

| F900 | 900 kN | Airports, container terminals |

You can also refer to AASHTO H-20 / H-25 standards for U.S. projects requiring specific vehicle load classes.

7. Product Customization

Galvanized steel trench covers can be tailored to your needs:

-

Material choice: Q235, Q345, SS304, SS316

-

Surface type: Plain, serrated, or checkered plate

-

Finish: Galvanized, painted (custom color), or untreated

-

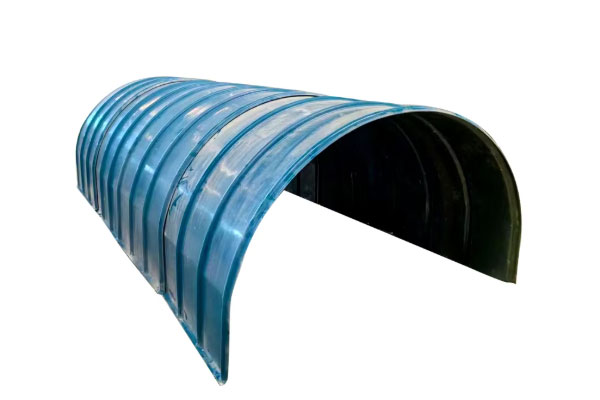

Shapes: Straight, curved, angled, T-junctions, or radial

-

Accessories: Frames, lifting handles, locking devices

8. Manufacturing Process

-

Raw Material Preparation – Steel flat bars and twisted rods or round bars are cut and prepared.

-

Assembly – Cross bars are inserted through slots in bearing bars using welding or pressure-locking.

-

Welding – Fully welded at intersections to ensure strength and durability.

-

Framing – Steel angle or flat bar frame welded around the edge.

-

Galvanizing – Entire assembly is hot-dip galvanized for long-term corrosion protection.

-

Penyelesaian – Surface inspection, quality control, and optional anti-slip nosing or lifting lugs.

9. Packaging and Delivery

-

Kemasan: Bundled with steel strips, wrapped with waterproof material for overseas shipping.

-

Optional: Palletized, wooden crates, or custom packaging available.

-

Delivery Time: 7–20 days depending on order volume and customization.

-

Shipping Methods: Sea freight, air cargo, or express delivery for urgent projects.

10. Quality Assurance

-

QC Process: Raw material inspection → Welding quality → Galvanization thickness → Final inspection

-

Sertifikasi: ISO 9001:2015, SGS, BV, TUV (as per customer request)

-

Third-Party Inspection: Available upon request

11. Environmental & Safety Considerations

-

Sustainable: Steel is 100% recyclable. Galvanizing extends lifespan, reducing replacement frequency.

-

LEED Credits: Eligible under LEED and other green building rating systems.

-

Worker Safety: Serrated surfaces and non-slip nosing options help meet workplace safety regulations.

12. Maintenance Guidelines

-

Routine Inspection: Check for loose fittings, corrosion spots, and debris blockage.

-

Pembersihan: Use water or pressure washing; avoid acidic or abrasive cleaning agents.

-

Repair: Minor galvanizing damage can be touched up with zinc-rich epoxy.

-

Replacement: Modular design allows replacing individual covers rather than the entire line.

13. Advantages Over Other Trench Cover Materials

| Fitur | Steel Grating | Concrete | FRP/Plastic |

|---|---|---|---|

| Load bearing | Tinggi | Medium | Low to medium |

| Berat | Sedang | Heavy | Light |

| Corrosion resistance | High (galvanized) | Rendah | Medium to high |

| Ventilation | Bagus sekali | None | Sedang |

| Fire resistance | Bagus sekali | Bagus sekali | Poor to moderate |

| Recyclability | 100% | Rendah | Partial |

| Lifespan | 30–50 years | 15–25 years | 10–20 years |

14. Case Studies / Project References

-

Shanghai Airport Stormwater Drainage

Installed D400-rated galvanized trench grates along 5 km of airport runway drainage. -

Petronas Oil Refinery (Malaysia)

Used stainless steel grating trench covers for chemical-resistant cable trenching. -

Johannesburg Cityscape Project

Custom recessed trench covers filled with granite to blend with urban paving.

15. Frequently Asked Questions (FAQ)

Q1: Can I request a specific load rating?

A: Yes, grating can be designed to meet EN 124 or AASHTO ratings.

Q2: Is this product slip-resistant?

A: Serrated bearing bars offer anti-slip properties ideal for slippery zones.

Q3: Can I order non-galvanized trench covers?

A: Yes, bare steel or painted finishes are available on request.

Q4: Can the trench cover be locked?

A: Yes, options for hinges and padlock systems are available for security.

Kesimpulan

Itu Galvanized Steel Grating Trench Cover is a high-performance solution for trench safety, drainage, and infrastructure access across multiple industries. Combining strength, durability, anti-corrosion performance, and safety features, it stands as a superior alternative to traditional covers. Fully customizable and compliant with global standards, it is an essential component in modern infrastructure design.

Galvanized Steel Grating Trench Cover

Seri :

Produk Proksi >aplikasi

Industrial Facilities Used as stair treads for access stairs, maintenance platforms, and mezzanine floors in factories and plants. ✅ Energy & Petrochemical Plants Resistant to corrosion from chemicals and moisture, suitable for oil rigs, refineries, and offshore platforms. ✅ Public Infrastructure Ideal for metro stations, pedestrian bridges, and access platforms in transport terminals. ✅ Water Treatment & Dams Non-slip and corrosion-resistant performance make it ideal for wet or underwater applications. ✅ Mining & Quarrying Supports heavy-duty foot traffic and equipment access in rugged and dusty environments. ✅ Architectural & Commercial Modern staircases, decorative balconies, and industrial-style interiors benefit from the strength and design flexibility.

Nama merk :

komposit TF

Nama Produk :

Galvanized Steel Grating Trench Cover

Pertanyaan Umum

Q :

What materials are used to manufacture these trench covers?

A :

Most trench covers are made from: Low carbon steel (Q235/Q195) – economical and strong Stainless steel (304/316) – corrosion-resistant for chemical or marine environments Hot-dip galvanized steel – standard for long-term outdoor and industrial use

Q :

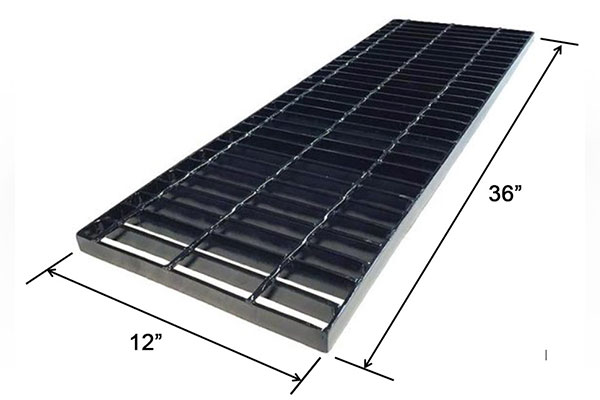

What are the standard sizes of trench covers?

A :

Sizes are customizable, but common options include: Width: 150 mm to 1000 mm+ Length: Usually 1000 mm, modular format for longer trenches Bar pitch: 30 mm or 40 mm Cross bar spacing: 50 mm or 100 mm Custom sizes, shapes (T-shape, corner, radial), and load ratings can be manufactured based on your trench design.

Q :

What load classes are available for galvanized trench grating?

A :

Trench covers are made to support different load ratings: Light duty (Class A15, B125) – for foot traffic or light vehicles Medium duty (Class C250, D400) – for cars, trucks, forklifts Heavy duty (Class E600, F900) – for ports, airports, and heavy equipment Compliant with EN 124, AASHTO, or AS 3996 standards.

Q :

Can the trench covers be locked or secured?

A :

Yes. Many trench grates can be equipped with: Hinges Bolted frames Locking plates or padlock tabs This prevents unauthorized access or theft and is commonly used in utility corridors and telecom installations.

Q :

Are anti-slip options available?

A :

Yes. You can choose: Serrated bearing bars – provide extra grip in wet or oily environments Checkered plate top cover – flat steel plate with raised patterns These are ideal for pedestrian zones, food plants, or outdoor settings.

Produk terkait lainnya