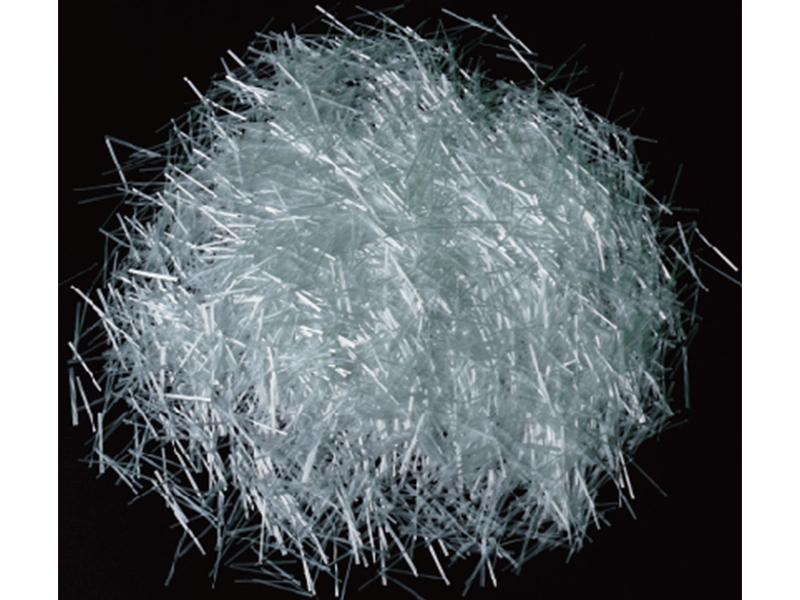

Untwisted roving is a key reinforcement material used primarily in the filament winding process for producing composite structures such as pressure vessels, chemical storage tanks, pipes, and wind turbine blades. Unlike traditional yarns or twisted rovings, untwisted roving offers superior resin impregnation, improved fiber alignment, and optimized mechanical performance, making it a critical component in high-strength, corrosion-resistant, and lightweight composite products.

Pengenalan kinerja produk

The term “untwisted” refers to the absence of intentional twist in the roving. This structural characteristic minimizes gaps between filaments and promotes full utilization of fiber strength, leading to better fiber-to-resin interaction, easier impregnation, and more uniform stress distribution.

2. Filament Winding Process Overview

Filament winding is a fabrication technique that involves winding continuous fiber strands impregnated with resin onto a rotating mandrel. After winding, the resin is cured (typically thermally), and the mandrel is removed to yield a hollow, composite part.

Key Stages in Filament Winding:

-

Fiber delivery: Untwisted roving is pulled from the creel under controlled tension.

-

Resin impregnation: Roving is passed through a resin bath or injection system.

-

Mandrel winding: The fiber is wound onto a rotating mandrel at specific angles (hoop, helical, polar).

-

Pengobatan: The wound part is cured using heat or UV light to harden the resin.

-

Demolding: The mandrel is removed, and the composite part is trimmed.

Untwisted roving is especially suited for this process due to its dimensional stability, consistent tension handling, and excellent wet-out behavior.

3. Product Characteristics of Untwisted Roving for Winding

| Fitur | Manfaat |

|---|---|

| No Twist | Maximizes tensile strength, minimizes filament misalignment |

| Controlled Linear Density | Ensures consistent thickness and mass flow during winding |

| Excellent Wet-Out | Promotes full fiber-resin contact, improves interfacial bonding |

| Compatible Sizing | Chemically tailored for polyester, vinyl ester, or epoxy systems |

| Low Static Generation | Improves processing stability, reduces fly or fuzz |

| Kekuatan Tarik Tinggi | Suitable for structural and pressure-bearing applications |

| Uniform Tex Distribution | Reduces variability in part thickness and mechanical properties |

| Optimized Spooling | Compatible with high-speed winding operations |

4. Applications of Untwisted Roving for Winding

4.1 Pressure Vessels

-

Gas storage cylinders (e.g., CNG, hydrogen)

-

Fire extinguishers

-

Air receivers

4.2 Industrial Pipes

-

Chemical-resistant piping

-

Sewer and wastewater pipes

-

Underground ducting

4.3 Tanks and Silos

-

Acid storage tanks

-

Fertilizer tanks

-

Brine and water tanks

4.4 Infrastructure and Energy

-

Wind turbine blades (spar caps)

-

Composite light poles

-

Electrical utility enclosures

4.5 Aerospace and Defense

-

Rocket casings

-

Structural shells

-

Filament wound casings for drones

5. Technical Requirements

Untwisted rovings for winding must meet specific mechanical and processing benchmarks:

| Requirement | Keterangan |

|---|---|

| Linear Density (Tex) | Ranges from 2400 – 9600 tex; selected based on winding speed and part thickness |

| Moisture Content | <0.10% for optimal resin bonding and reduced void formation |

| Diameter Filamen | 13 – 24 microns, typically uniform for consistent strength |

| Daya tarik | > 2000 MPa to meet pressure-bearing standards |

| Kompatibilitas Resin | Sizing must match resin type (polyester, epoxy, vinyl ester) |

| Spool Design | Traverse and tension settings matched to creel and winding setup |

| Unwinding Behavior | Smooth payout, minimal snags or strand breakage |

| Shelf Life | 12–24 months in controlled storage |

6. Technical Data Sheet (TDS)

Nama Produk: Untwisted Roving for Filament Winding

Glass Type: E-glass

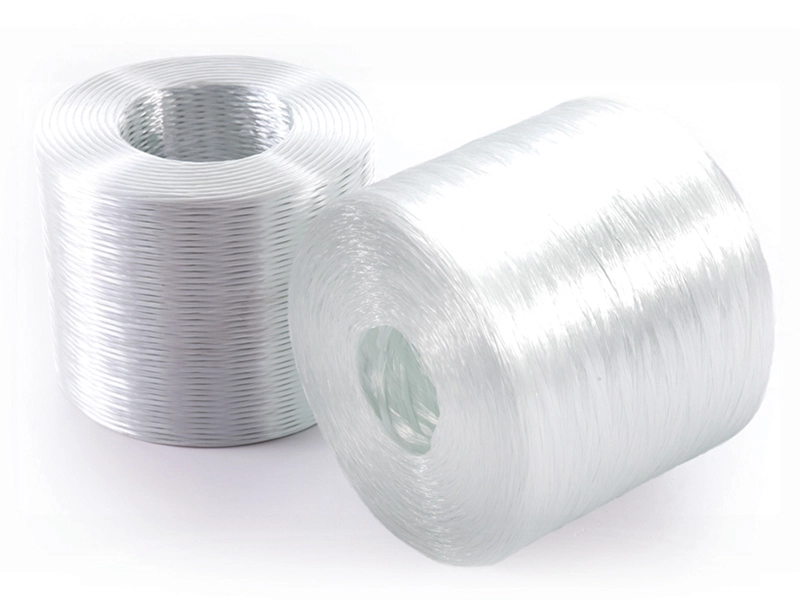

Product Form: Continuous, untwisted strands wound onto cylindrical bobbins

6.1 Physical Properties

| Properti | Typical Value | Metode Tes |

|---|---|---|

| Diameter Filamen | 13 – 24 μm | ISO 1888 |

| Linear Density (Tex) | 2400 / 4800 / 9600 tex | ISO 1889 |

| Moisture Content | ≤ 0.10% | ISO 3344 |

| Loss on Ignition (LOI) | 0.80% – 1.30% | ISO 1887 |

| Kepadatan | 2.6 g/cm³ | ASTM D792 |

| Bobbin Weight | 15 – 25 kg | Internal Standard |

| Package Dimensions | Ø 270mm × H 260mm (customizable) | Manufacturer Spec |

| Warna | Natural White | Visual Inspection |

6.2 Mechanical Properties

| Properti | Typical Value | Metode Tes |

|---|---|---|

| Daya tarik | ≥ 2300 MPa | ASTM D2343 |

| Tensile Modulus | ≥ 72 GPa | ASTM D2343 |

| Elongation at Break | 2.1% – 2.5% | ASTM D2343 |

| Compatibility (Polyester) | Bagus sekali | Wet-Out Rating (1–5) |

| Compatibility (Epoxy) | Bagus sekali | Wet-Out Rating (1–5) |

| Static Buildup | Negligible | Manufacturer Test |

| Resin Wet-Out Time | < 30 seconds | Visual Test |

7. Packaging and Logistics

Kemasan

-

Bobbins wound on cardboard tubes (3-inch core diameter)

-

Polyethylene-wrapped, then palletized

-

Pallet: 1.1m × 1.1m, holds 48–64 bobbins depending on size

-

Stretch-wrapped with corner protectors

Labeling

Each bobbin includes:

-

Product code and tex

-

Gross/net weight

-

Batch number

-

Date of manufacture

-

Resin compatibility

8. Storage and Shelf Life

-

Temperature: 15 – 35°C

-

Humidity: ≤ 65% RH

-

Conditions: Keep dry, avoid sunlight and temperature cycling

-

Shelf Life: 12 months under normal conditions; extendable to 24 months in climate-controlled warehousing

9. Processing Recommendations

| Process Parameter | Recommendation |

|---|---|

| Creel Setup | Use low-friction ceramic eyelets or pulleys |

| Tension Control | Maintain 1.0–1.8 N per strand, uniform across bobbins |

| Impregnation | Use resin bath or pressure impregnation system |

| Resin Viscosity | 300–1000 cps depending on fiber speed and part size |

| Mandrel Speed | 50 – 200 RPM (application-dependent) |

| Curing Temperature | 80 – 160°C (resin-specific) |

| Pull Speed | 2 – 6 m/min |

Tips

-

Always condition fiber in production environment for 24 hours before use.

-

Replace damaged bobbins to prevent strand inconsistency.

-

Ensure continuous fiber tension during splicing or bobbin changeover.

10. Health and Safety

Precautions

-

Glass fiber dust may irritate eyes, skin, or respiratory system.

-

Handle with gloves and wear safety glasses during installation.

First Aid Measures

-

Eye contact: Rinse with clean water for 15 minutes.

-

Skin irritation: Wash with soap and water.

-

Inhalation: Move to fresh air, use respiratory protection if necessary.

Refer to the MSDS for full H&S guidance.

11. Quality Standards

| Certification | Keterangan |

|---|---|

| ISO 9001 | Quality Management System |

| ISO 14001 | Environmental Management |

| REACH Compliant | Chemical Safety Regulation |

| RoHS Compliant | Restriction of Hazardous Substances |

| UL, ASTM, or DIN tests | Available upon request |

12. Environmental Considerations

-

Recyclability: Glass fiber offcuts may be reprocessed as filler material.

-

Keberlanjutan: Inert material, non-toxic and durable.

-

Compliance: Meets EU and US regulations for environmental health and safety.

13. Customization Options

Manufacturers can provide tailored variants based on:

-

Tex/yield requirements

-

Resin compatibility (epoxy, polyester, vinyl ester, phenolic)

-

Filament diameter optimization

-

Bobbin size customization for your winding machine

-

Sizing chemistry tailored to specialty applications (e.g., UV resistance, flame retardancy)

14. Manufacturer Technical Support

Top suppliers offer:

-

On-site process optimization

-

Engineering support for mandrel and resin matching

-

Spooling design consultation

-

Fiber testing and quality validation

15. Conclusion

Untwisted roving for winding is a cornerstone material in the filament winding process, valued for its clean fiber alignment, superior wet-out, high strength, and process consistency. Its versatility and performance make it ideal for advanced composite applications in infrastructure, aerospace, automotive, and industrial manufacturing.

With customizable options, robust quality control, and excellent mechanical properties, untwisted roving delivers enhanced productivity and long-term reliability in any high-performance filament winding application.

Untwisted roving for winding

aplikasi

Otomotif / Barang Konsumsi dan Peralatan Bisnis / Olah Raga dan Rekreasi / Listrik dan Elektronika / Bangunan dan Konstruksi / Infrastruktur

Jenis kaca:

E

Nama Produk :

Untwisted roving for winding

Pertanyaan Umum

Q :

Apakah Anda seorang pabrik? Di mana kau berada?

A :

Kami adalah produsen profil FRP grating dan pultruded, pedagang bahan benang FRP. Kami merupakan distributor terbesar China Jushi Co. Kami juga menjual produk dari beberapa produsen benang FRP. Kami berada di Anhui, Tiongkok.

Q :

Informasi apa yang direkomendasikan untuk penyelidikan?

A :

1. Teks mana yang Anda butuhkan? 2. Aplikasi apa yang Anda gunakan? Atau teknologinya, tenun, pultrusion, atau lilitan? 3. Berapa jumlah yang Anda butuhkan? 4. Resin apa yang Anda gabungkan? Resin poliester atau resin epoksi? 5. Apakah Anda memerlukan harga FOB atau CIF, jika CIF, silakan beritahu kami port Anda.

Q :

Apa MOQnya?

A :

Biasanya 1 Ton

Q :

Paket & Pengiriman

A :

Paket normal: karton (Termasuk dalam harga satuan) Paket Khusus: perlu dikenakan biaya sesuai situasi aktual. Pengiriman normal: Pengiriman barang yang Anda pilih.

Q :

Kapan saya bisa menawarkan?

A :

Kami biasanya mengutip dalam waktu 24 jam setelah kami menerima pertanyaan Anda. Jika Anda sangat mendesak untuk mendapatkan harga, silakan hubungi kami atau beri tahu kami di email Anda, sehingga kami dapat membalas prioritas Anda.

Q :

Bagaimana Anda membebankan biaya sampel?

A :

Jika Anda memerlukan sampel dari stok kami, kami dapat menyediakannya secara gratis, tetapi Anda harus membayar biaya pengiriman. Jika Anda memerlukan ukuran khusus, Kami akan membebankan biaya pembuatan sampel yang dapat dikembalikan saat Anda melakukan pemesanan.

Q :

Berapa waktu pengiriman Anda untuk produksi?

A :

Jika kami memiliki stok, dapat dikirim dalam 7 hari; jika tanpa stok, perlu 7 ~ 15 hari!

Produk terkait lainnya