Introduzione alle prestazioni del prodotto

Heavy-duty steel grating is a robust and versatile material designed to handle extremely high loads, such as vehicular traffic, industrial machinery, and other heavy applications. Its design, materials, and manufacturing processes make it an essential component in industrial and commercial settings where strength and durability are paramount.

Key Features of Heavy-Duty Steel Grating

-

High Load-Bearing Capacity:

- Specifically engineered to withstand the weight of heavy vehicles, equipment, and machinery.

- Suitable for dynamic and static loads.

-

Durable and Long-Lasting:

- Resistant to wear and tear, ensuring longevity even under harsh conditions.

- High resistance to impact and deformation.

-

Resistenza allo scivolamento:

- Often manufactured with serrated surfaces or added traction features for enhanced safety.

-

Resistenza alla corrosione:

- Available with protective coatings such as galvanization or powder coating for improved performance in corrosive environments.

-

Open Design:

- Allows for drainage, ventilation, and the passage of light, reducing water accumulation and ensuring better maintenance.

-

Personalizzabile:

- Can be tailored to meet specific load requirements, dimensions, and finishes for various applications.

Specifications of Heavy-Duty Steel Grating

1. Materials

- Carbon Steel:

- Most common material, offering excellent strength and cost-effectiveness.

- Typically hot-dip galvanized to prevent corrosion.

- Stainless Steel:

- Provides superior corrosion resistance and is used in environments exposed to chemicals, moisture, or extreme weather.

- Alloy Steel:

- Suitable for specialized applications requiring extra durability and resistance to wear.

2. Bar Dimensions

- Bearing Bar Size:

- Thickness: Commonly ranges from 6mm to 15mm.

- Depth: Ranges from 25mm to 200mm depending on load requirements.

- Spacing:

- Common spacing between bearing bars: 30mm, 40mm, 50mm, or custom configurations.

- Spacing between crossbars: 50mm or 100mm (standard).

3. Load Ratings

- Designed to support heavy vehicular loads (e.g., trucks, forklifts, cranes) and industrial machinery.

- Compliance with standards such as ANSI/NAAMM MBG 531 or BS 4592 ensures structural integrity under defined loads.

4. Surface Types

- Plain Surface:

- Smooth and clean, suitable for indoor or low-risk environments.

- Serrated Surface:

- Serrated bearing bars enhance grip and safety in wet, oily, or hazardous conditions.

5. Finishes

- Hot-Dip Galvanized:

- Provides a zinc coating for rust resistance, ideal for outdoor or corrosive environments.

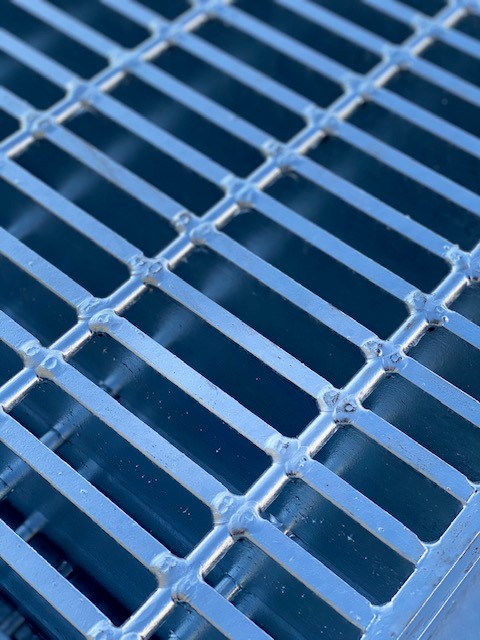

- Painted or Powder-Coated:

- Enhances appearance and adds a layer of protection.

- Untreated:

- Often used when additional coatings will be applied after installation.

Manufacturing and Construction

1. Fabrication Methods

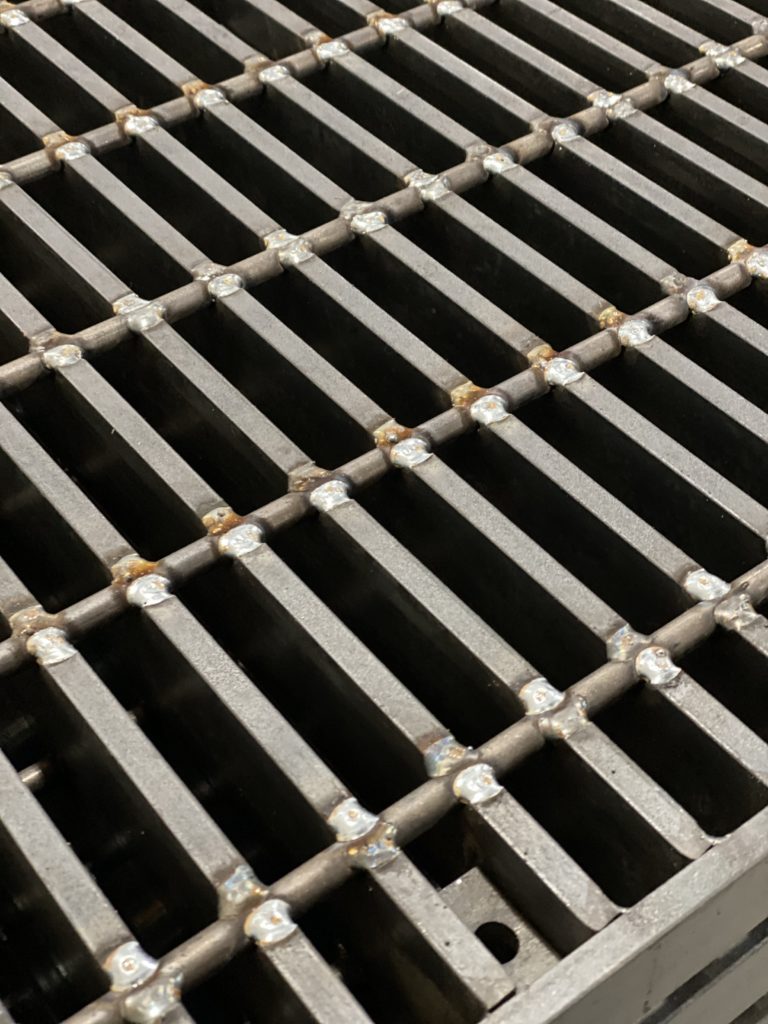

- Welded Grating:

- Bearing bars and crossbars are welded at intersections, creating a strong and rigid structure.

- Press-Locked Grating:

- Bars are mechanically pressed together without welding, offering a smoother surface and clean appearance.

- Grata rivettata:

- Crossbars are riveted to bearing bars, providing exceptional strength for heavy loads.

2. Types of Heavy-Duty Steel Grating

- Standard Rectangular Grating:

- The most common, with rectangular openings.

- Heavy-Duty Steel Plate Grating:

- Uses thicker and deeper bars for extreme load requirements.

- Trench Grates and Covers:

- Designed for drainage systems, capable of bearing heavy vehicular loads.

Applications of Heavy-Duty Steel Grating

-

Pavimentazione Industriale:

- Used in factories, warehouses, and processing plants to support heavy equipment.

-

Bridge Decking:

- Provides a lightweight yet strong alternative for bridge surfaces, capable of handling vehicle loads.

-

Trench and Drain Covers:

- Commonly installed in areas requiring drainage with the ability to support vehicular traffic.

-

Loading Docks and Ramps:

- Ideal for docks where forklifts and other heavy machinery operate.

-

Offshore Platforms:

- Durable and corrosion-resistant grating for oil rigs and marine environments.

-

Parking Garages:

- Used for ramp surfaces, ventilation covers, and pedestrian walkways.

-

High-Traffic Walkways and Catwalks:

- Provides sturdy, non-slip pathways in industrial and commercial settings.

Installation Guidelines

-

Proper Support Structure:

- Ensure the support beams or frame are capable of bearing the anticipated load.

-

Fastening Methods:

- Use clips, bolts, or welding to secure the grating to the structure.

- Avoid loose fittings, which can compromise safety.

-

Alignment and Spacing:

- Maintain uniform spacing to ensure even load distribution and safety.

-

Inspection and Maintenance:

- Regularly inspect for signs of wear, corrosion, or loosening fasteners.

Advantages of Heavy-Duty Steel Grating

- Forza: Can withstand immense loads without deformation.

- Safety: Slip-resistant surfaces and open design reduce risks in hazardous environments.

- Durabilità: Long-lasting performance with minimal maintenance.

- Versatility: Suitable for a wide range of industries and environments.

- Eco-Friendly: Steel is recyclable, making it an environmentally responsible choice.

Heavy-Duty Grating Standards

- ANSI/NAAMM MBG 531: Provides guidelines for metal bar grating in terms of load and deflection.

- ASTM A123/A123M: Standard for galvanization of steel.

- BS 4592: British standard for industrial flooring and stair treads.

- ISO 9001: Ensures consistent quality in manufacturing processes.

Customizations

-

Size and Shape:

- Custom dimensions to fit specific applications.

- Shapes include rectangular, square, or irregular configurations for special installations.

-

Load Capacities:

- Engineered to meet precise load and deflection criteria.

- Tailored for static or dynamic loads.

-

Coatings and Finishes:

- Additional options for environments requiring extra corrosion resistance or decorative elements.

-

Surface Patterns:

- Custom serration patterns for specialized slip-resistance requirements.

Conclusione

Heavy-duty steel grating is an essential material for applications demanding high strength, durability, and safety. Its wide range of specifications, materials, and finishes ensures it can be customized to meet the exact requirements of various industries, from industrial flooring to bridge decking. Proper selection, installation, and maintenance of heavy-duty grating guarantee long-term performance and reliability in even the harshest conditions.

Heavy-Duty Steel Grating: Detailed Overview and Specifications

Serie:

Prodotti proxy >applicazione

FAQ

Altri prodotti correlati