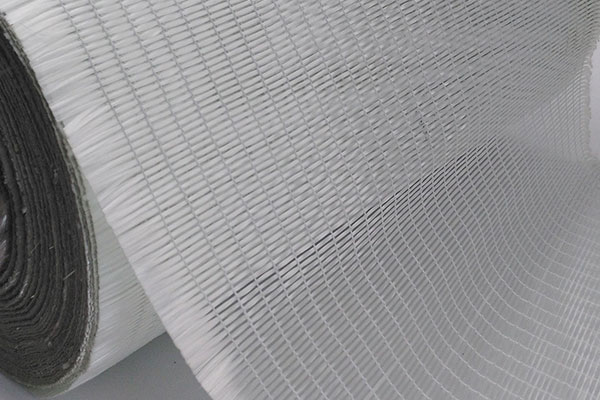

Glass fiber unidirectional fabric is a high-performance reinforcement material made from continuous glass fibers oriented in a single direction. It is typically used in composite manufacturing, providing enhanced strength, stiffness, E durability to a wide range of products. The fabric is produced by weaving or stitching glass fibers parallel to one another, which allows it to carry loads predominantly along the fibers' axis.

Introduzione alle prestazioni del prodotto

Unidirectional glass fiber fabric is most commonly used in applications requiring high tensile strength E low weight, such as aerospace, settore automobilistico, marine, E sports equipment industries. Its properties make it ideal for laminated composites where directional reinforcement is required, as the fibers align with the principal stress direction.

General Product Parameters:

-

Materiale: Glass fiber (E-glass, S-glass, or other specialized grades)

-

Weave type: Unidirectional, where all fibers are aligned in one direction

-

Peso: Typically between 150 to 1000 gsm (grams per square meter), depending on the application and performance requirements

-

Larghezza: Generally available in standard widths ranging from 100 mm to 1000 mm, but customized widths can be produced

-

Spessore: Varies depending on weight, typically ranging from 0.1 mm to 0.5 mm for standard fabrics

-

Fiber orientation: 0° (unidirectional) fibers with parallel alignment to the length of the fabric

-

Resin compatibility: Compatible with a range of resins, including epossidico, poliestere, E vinyl ester, depending on the final application and performance requirements

-

Tensile strength: Typically ranges from 3000 MPa to 4500 MPa depending on the fiber type (E-glass or S-glass)

-

Allungamento: Typically in the range of 2-5% depending on the type of glass fiber used

-

Thermal resistance: Can withstand temperatures up to 550°C, with minimal loss of strength, depending on the resin used

-

Moisture absorption: Very low, making it suitable for use in marine environments

-

Colore: Typically white or light grey, though other colors may be available with specific resin or finish applications

Applicazioni:

-

Aerospaziale: Used in manufacturing lightweight composite structures, such as wings, fuselage parts, and interior panels.

-

Settore automobilistico: Used in car body panels, reinforcement for structural parts, and lightweight composite components that require high mechanical properties.

-

Marino: Applied in boat hulls, decks, and other boat components exposed to harsh marine environments.

-

Wind Energy: Reinforcement of wind turbine blades and other composite structures subjected to high stress.

-

Attrezzatura sportiva: Used in the manufacturing of bicycle frames, ski poles, hockey sticks, and other equipment requiring high strength and light weight.

-

Costruzione: Glass fiber unidirectional fabric is also used in reinforcing concrete E structural composites to enhance the overall mechanical properties of the materials.

Benefici:

-

Directional strength: The primary benefit of unidirectional glass fiber fabric is its ability to provide high strength E stiffness in the direction of the fibers, which can be crucial for certain load-bearing applications.

-

Leggero: Offers excellent strength-to-weight ratios, making it an ideal solution for industries where minimizing weight is crucial, such as aerospace and automotive.

-

Personalizzabile: Can be tailored to specific requirements, such as varying fiber orientations, weight, and resin compatibility.

-

Durabilità: The fabric is resistant to wear, tear, and environmental degradation, making it suitable for long-lasting applications.

Glass Fiber Unidirectional Fabric

Serie:

Glass Fiber Fabric >applicazione

FAQ

Q :

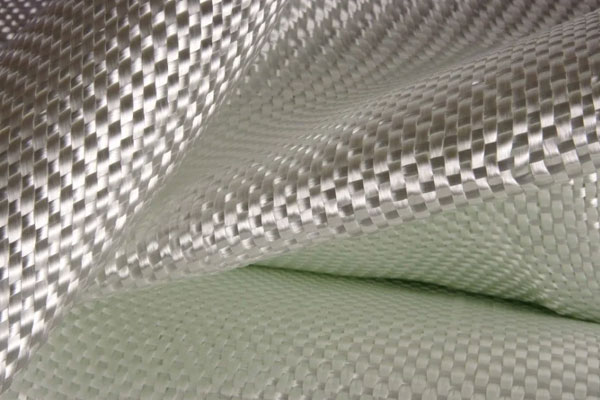

What is the difference between unidirectional and woven glass fiber fabric?

UN :

The primary difference lies in the fiber orientation: Unidirectional fabric has fibers aligned in a single direction, which provides high strength and stiffness along that axis but minimal strength in perpendicular directions. Woven fabric features fibers arranged in both warp (vertical) and weft (horizontal) directions, giving more balanced mechanical properties in both directions but typically less strength than unidirectional fabrics in a single direction.

Q :

What industries use glass fiber unidirectional fabric?

UN :

Glass fiber unidirectional fabric is widely used in industries such as: Aerospace (for lightweight and strong parts) Automotive (for reinforced body panels and structural parts) Marine (for boat hulls and deck reinforcements) Wind energy (for reinforcing turbine blades) Sports equipment (such as bicycles, skis, and sporting goods) Construction (for concrete reinforcement and structural composites)

Q :

What resin should I use with unidirectional glass fiber fabric?

UN :

Unidirectional glass fiber fabric is compatible with a variety of resins, but epoxy resin is most commonly used due to its strong adhesion, low viscosity, and superior mechanical properties. Other resins, such as polyester and vinyl ester, can also be used, but epoxy is preferred for applications that require higher strength, durability, and resistance to environmental factors.

Q :

How do I lay up glass fiber unidirectional fabric for composite manufacturing?

UN :

To lay up unidirectional glass fiber fabric, follow these general steps: Prepare the mold: Ensure the mold is clean and properly treated for resin bonding. Cut the fabric: Cut the fabric to the desired size and shape, ensuring the fibers are aligned with the primary stress direction. Apply resin: Wet out the fabric with resin, ensuring even saturation. Use a roller or brush to spread the resin across the surface of the fabric. Layer the fabric: Place each layer of fabric in the mold, aligning the fibers in the same direction for each layer. For increased strength, additional layers can be added, each with fibers in the same direction. Cure: Allow the composite to cure according to the resin manufacturer’s instructions (typically in an oven or at room temperature with hardener).

Q :

What are the benefits of using glass fiber unidirectional fabric in composite materials?

UN :

High strength-to-weight ratio: Provides exceptional reinforcement with minimal weight increase, crucial for industries such as aerospace and automotive. Tailored properties: By controlling the fiber orientation, the material's strength and stiffness can be optimized for specific load-bearing directions. Durability: Resistant to moisture, heat, and chemicals, making it ideal for use in harsh environments like marine and industrial applications. Cost-effectiveness: While stronger composites can be more expensive, glass fiber is generally a more cost-effective alternative to other materials like carbon fiber, especially for less demanding applications.

Altri prodotti correlati