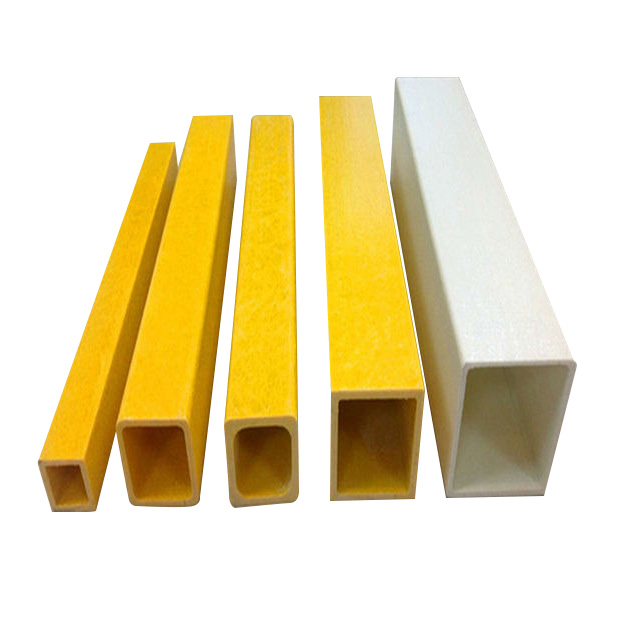

A GRP (Glass Reinforced Plastic) Box Section, also known as an FRP (Fiberglass Reinforced Plastic) Square or Rectangular Tube, is a hollow structural profile made from a composite of glass fibers and polymer resin. It is manufactured through the pultrusion process, ensuring high strength, durability, and uniform quality.

Introduzione alle prestazioni del prodotto

GRP Box Sections are commonly used as load-bearing structures in construction, industrial, marine, and electrical applications where corrosion resistance, lightweight properties, and high mechanical strength are required.

2. Conventional Specifications & Dimensions

GRP Box Sections are available in square and rectangular profiles, with different thicknesses based on load requirements.

Common Dimensions (mm & inches)

| Size (mm) | Wall Thickness (mm) | Size (inches) | Wall Thickness (inches) |

|---|---|---|---|

| 25 x 25 | 3, 4 | 1" x 1" | 0.12", 0.16" |

| 30 x 30 | 4, 5 | 1.18" x 1.18" | 0.16", 0.20" |

| 40 x 40 | 4, 5, 6 | 1.57" x 1.57" | 0.16", 0.20", 0.24" |

| 50 x 50 | 5, 6, 8 | 1.97" x 1.97" | 0.20", 0.24", 0.31" |

| 75 x 75 | 6, 8, 10 | 2.95" x 2.95" | 0.24", 0.31", 0.39" |

| 100 x 100 | 8, 10, 12 | 3.94" x 3.94" | 0.31", 0.39", 0.47" |

| 150 x 150 | 10, 12, 15 | 5.91" x 5.91" | 0.39", 0.47", 0.59" |

📌 Rectangular sections with different height/width ratios are also available upon request.

Standard Lengths

-

3m, 6m, 12m (custom lengths available)

Composizione del materiale

-

Rinforzo in fibra di vetro – Provides tensile strength and durability.

-

Polymer Resin Options:

-

Poliestere – Standard, cost-effective.

-

Vinilestere – Superior corrosion resistance.

-

Fenolico – Fire-resistant, low smoke emission.

-

Epoxy – High strength and impact resistance.

-

Opzioni colore

-

Standard: Gray, Green, Yellow, Red, Black

-

Custom colors available based on resin pigmentation.

3. Key Advantages of GRP Box Sections

| Caratteristica | GRP Box Section | Steel Box Section | Aluminum Box Section |

|---|---|---|---|

| Resistenza alla corrosione | ✅ Excellent (Resists chemicals, moisture, saltwater) | ❌ Prone to rust and corrosion | ⚠️ Corrosion-resistant but may oxidize |

| Peso | ✅ Lightweight (~75% lighter than steel) | ❌ Heavy | ✅ Lighter than steel but heavier than GRP |

| Strength-to-Weight Ratio | ✅ High | ✅ High | ✅ High |

| Electrical Insulation | ✅ Non-conductive | ❌ Conductive | ❌ Conductive |

| Thermal Conductivity | ✅ Low (Good insulation) | ❌ High (conducts heat) | ⚠️ Medium |

| Maintenance | ✅ Low maintenance | ❌ Requires painting, coating | ✅ Low maintenance |

| Installation | ✅ Easy (can be cut & drilled on-site) | ❌ Requires welding, heavy tools | ✅ Moderate |

| Lifespan | ✅ 20+ years | ❌ Subject to corrosion | ✅ 10–15 years |

📌 Key Takeaways

-

GRP Box Sections do not rust or corrode, making them ideal for outdoor and harsh environments.

-

Lighter than steel, making handling and installation easier.

-

Non-conductive, ideal for electrical safety applications.

-

Minimal maintenance required, reducing long-term costs.

4. Applications of GRP Box Sections

GRP Box Sections are used in multiple industries, including:

🏗 Construction & Infrastructure – Roof frames, structural supports, handrails.

⚡ Electrical Industry – Non-conductive framing, transformer enclosures.

🌊 Marine & Offshore – Dock structures, platforms, bridges.

🏭 Chemical Plants & Wastewater Facilities – Corrosion-resistant frameworks.

🚆 Trasporti – Railway signal poles, lightweight vehicle structures.

🌿 Agriculture & Greenhouses – Corrosion-resistant structures.

5. Installation & Processing

Can GRP Box Sections be cut and drilled?

Yes! GRP Box Sections can be easily cut, drilled, and machined using:

-

Circular saws with diamond/tungsten carbide blades

-

Drills with HSS (High-Speed Steel) bits

-

Angle grinders for smooth finishing

💡 Tip: Always use dust extraction or wear a mask when cutting GRP to avoid inhaling fine dust.

Installation Methods:

-

Bolts & Fasteners – Pre-drilled for easy connection.

-

Adhesives & Bonding Agents – For seamless joints.

-

Brackets & Clamps – Used for structural connections.

6. Fire Resistance of GRP Box Sections

GRP Box Sections can be fire-retardant depending on the resin used:

🔥 Standard Polyester Resin – Basic fire resistance.

🔥 Resina Vinilestere – Moderate fire resistance.

🔥 Resina fenolica – High fire resistance, low smoke emissions, used in public spaces.

Always check fire safety regulations before selecting a resin type.

7. Cost Considerations

The cost of GRP Box Sections depends on:

💰 Size & thickness

💰 Resin type (Standard polyester is cheaper; phenolic is premium)

💰 Quantity ordered (Bulk orders receive better pricing)

💰 Personalizzazione (Custom colors, lengths, or fire-retardant versions may add costs)

📌 While the initial cost is higher than steel, GRP requires lower maintenance, making it cost-effective long-term.

8. Lifespan & Maintenance

⏳ Lifespan: 20+ years in normal conditions.

🧼 Manutenzione:

-

Regular cleaning – Use water and mild detergent.

-

Check for physical damage – Especially in high-load applications.

-

UV Protection (if needed) – Optional coatings can be applied.

Conclusione

GRP Box Sections are an excellent alternative to steel and aluminum, offering lightweight strength, corrosion resistance, and long-term durability. They are ideal for industrial, marine, construction, and electrical applications.

💡 Need a quotation or technical consultation? Let me know your project requirements! 🚀

GRP Box Section

Serie:

Prodotti principali >applicazione

✅ Industrial & Chemical Plants – Structural supports in corrosive environments. ✅ Marine & Offshore – Framing in docks, jetties, and oil platforms. ✅ Electrical Infrastructure – Insulating supports in substations. ✅ Wastewater Treatment Plants – Structural reinforcements in water tanks. ✅ Construction – Roof framing, wall supports, and lightweight structures. ✅ Transport Industry – Rail, automotive, and aerospace applications.

Marchio :

TFcomposito

Nome del prodotto :

GRP Box Section

Materiale :

Fibra di vetro

Colore :

Yellow,Gray,Other

FAQ

Q :

What are the standard sizes available?

UN :

GRP Box Sections are available in various sizes, with common dimensions including: 📌 Square Sections: 25 x 25 mm, 30 x 30 mm, 40 x 40 mm, 50 x 50 mm, 75 x 75 mm, 100 x 100 mm, 150 x 150 mm 📌 Rectangular Sections: 50 x 25 mm, 100 x 50 mm, 150 x 50 mm, 200 x 100 mm, etc. 📌 Wall Thickness Options: 3 mm to 15 mm 📌 Standard Lengths: 3m, 6m, 12m (Custom lengths available)

Q :

What are the main advantages of GRP Box Sections?

UN :

✅ Corrosion-resistant – No rust, ideal for harsh environments ✅ Lightweight – Up to 75% lighter than steel ✅ High strength-to-weight ratio – Strong but easy to handle ✅ Non-conductive – Safe for electrical applications ✅ Low maintenance – No need for painting or coatings ✅ Long lifespan – 20+ years in most conditions ✅ Easy to cut and install – No special tools required

Q :

Can GRP Box Sections be cut and drilled?

UN :

Yes! GRP can be easily cut, drilled, and machined using: Diamond or tungsten carbide saw blades High-speed steel (HSS) drill bits Angle grinders for finishing 📌 Tip: Wear a mask and use dust extraction to avoid inhaling fiberglass particles.

Q :

Are GRP Box Sections fire-resistant?

UN :

🔥 Standard GRP is fire-resistant to some extent, but enhanced fire-retardant resins can be used for better performance: Polyester Resin – Basic fire resistance Vinyl Ester Resin – Moderate fire resistance Phenolic Resin – High fire resistance, low smoke emission 📌 Always check fire safety regulations before selecting a resin type.

Q :

How are GRP Box Sections installed?

UN :

GRP Box Sections can be installed using: Bolts & fasteners – Pre-drilled for secure connections Brackets & clamps – Common for structural frames Adhesives – For bonding without drilling Fiberglass welding (resin bonding) – Permanent joint solution

Q :

What is the lifespan of a GRP Box Section?

UN :

🛠 20+ years with minimal maintenance. 🚫 No rust, no painting required. 📌 For extreme environments (chemical plants, offshore, etc.), lifespan may vary.

Q :

Can GRP Box Sections be painted?

UN :

Yes! GRP can be painted using UV-resistant coatings for additional protection. However, GRP profiles are available in different colors from the factory, so painting is usually unnecessary.

Q :

What industries use GRP Box Sections?

UN :

🔹 Construction & Infrastructure – Frames, walkways, handrails 🔹 Marine & Offshore – Platforms, docks, ladders 🔹 Electrical Industry – Transformer enclosures, supports 🔹 Chemical Plants & Factories – Corrosion-resistant structures 🔹 Agriculture & Greenhouses – Lightweight support frames

Q :

Are GRP Box Sections environmentally friendly?

UN :

♻️ Yes! GRP is highly durable, reducing waste over time. However, recycling GRP requires specialized facilities.

Altri prodotti correlati