A GRP (Glass Reinforced Plastic) Wide Flange Beam, also known as an FRP (Fiberglass Reinforced Plastic) Wide Flange Beam, is a structural profile designed to provide high strength, lightweight, and superior corrosion resistance. Unlike traditional steel beams, GRP wide flange beams are non-corrosive, non-conductive, and require minimal maintenance, making them ideal for applications in marine, chemical, industrial, and outdoor environments.

Introduzione alle prestazioni del prodotto

1. What is a GRP Wide Flange Beam?

A GRP (Glass Reinforced Plastic) Wide Flange Beam, also known as an FRP (Fiberglass Reinforced Plastic) Wide Flange Beam, is a structural profile designed to provide high strength, lightweight, and superior corrosion resistance. Unlike traditional steel beams, GRP wide flange beams are non-corrosive, non-conductive, and require minimal maintenance, making them ideal for applications in marine, chemical, industrial, and outdoor environments.

📌 Caratteristiche principali:

✅ Corrosion-resistant – Ideal for chemical plants, marine environments, and industrial applications.

✅ Lightweight but strong – 75% lighter than steel, making it easier to transport and install.

✅ Non-conductive – Electrically and thermally insulating for safe use in electrical environments.

✅ Low maintenance – No rusting, repainting, or chemical treatments needed.

✅ Fire retardant options available – Complies with international fire safety standards.

GRP Wide Flange Beam

2. Conventional Specifications & Dimensions

GRP Wide Flange Beams are available in different sizes to suit a variety of structural applications.

Common Sizes of GRP Wide Flange Beams

| Size (mm) | Flange Width (mm) | Web Thickness (mm) | Size (inches) | Flange Width (inches) | Web Thickness (inches) |

|---|---|---|---|---|---|

| 100 x 100 x 6 | 100 | 6 | 4" x 4" x 0.24" | 4" | 0.24" |

| 150 x 150 x 8 | 150 | 8 | 6" x 6" x 0.31" | 6" | 0.31" |

| 200 x 200 x 10 | 200 | 10 | 8" x 8" x 0.39" | 8" | 0.39" |

| 250 x 250 x 12 | 250 | 12 | 10" x 10" x 0.47" | 10" | 0.47" |

| 300 x 300 x 15 | 300 | 15 | 12" x 12" x 0.59" | 12" | 0.59" |

📌 Standard Lengths: 3m, 6m, 12m (custom lengths available upon request).

3. Key Advantages of GRP Wide Flange Beams

✅ Resistenza alla corrosione – Perfect for use in harsh environments like marine, offshore, and chemical processing industries.

✅ Lightweight yet Strong – Up to 75% lighter than steel, allowing for easier transportation and installation without heavy equipment.

✅ Isolamento elettrico e termico – Does not conduct electricity or heat, making it safe for power plants and electrical substations.

✅ Weather Resistant – Resistant to UV exposure, moisture, and extreme temperatures.

✅ Opzioni ignifughe – Available in fire-resistant resin formulations meeting BS 476, ASTM E84, and EN 13501 standards.

✅ Bassa manutenzione – No need for repainting, coating, or rust prevention treatments.

✅ Easy to Process & Install – Can be cut, drilled, and bonded with standard tools.

4. Comparison: GRP Wide Flange Beam vs. Steel vs. Aluminum

| Proprietà | GRP Wide Flange Beam | Steel Wide Flange Beam | Aluminum Wide Flange Beam |

|---|---|---|---|

| Resistenza alla corrosione | ✅ Excellent | ❌ Prone to rust | ⚠️ Moderate |

| Peso | ✅ Lightweight | ❌ Heavy | ✅ Lighter than steel |

| Strength-to-Weight Ratio | ✅ High | ✅ High | ✅ High |

| Electrical Insulation | ✅ Non-conductive | ❌ Conductive | ❌ Conductive |

| Thermal Conductivity | ✅ Low | ❌ High | ⚠️ Medium |

| Maintenance | ✅ Minimal | ❌ Requires coatings | ✅ Minimal |

| Lifespan | ✅ 20+ years | ❌ Prone to corrosion | ✅ 10-15 years |

5. Types of GRP Wide Flange Beams Based on Resin Composition

📌 Polyester Resin – Cost-effective, general-purpose use.

📌 Resina Vinilestere – Superior chemical and corrosion resistance.

📌 Resina fenolica – Fire-resistant, low smoke emission.

📌 Resina epossidica – High mechanical strength, impact resistance.

6. Applications of GRP Wide Flange Beams

🏗 Construction & Infrastructure – Bridges, platforms, walkways, and support structures.

🏭 Industrial Plants – Used in corrosive environments for durable structural support.

🌊 Marine & Offshore – Shipbuilding, oil rigs, and seawater-exposed structures.

⚡ Electrical Installations – Safe framework for substations and power plants.

🚇 Transport & Rail – Lightweight reinforcements for railway and metro projects.

🏡 Architectural & Landscaping – Outdoor structures resistant to weathering.

7. GRP Wide Flange Beam Installation & Processing

🛠 Cutting: Can be cut with carbide or diamond-tipped saws.

🔩 Fastening: Can be drilled with standard HSS drill bits and secured with stainless steel bolts.

🛠 Incollaggio: Can be bonded using structural adhesives for added strength.

📌 Tip: Use protective equipment and proper ventilation when cutting or drilling GRP materials.

8. Fire Resistance of GRP Wide Flange Beams

🔥 Standard GRP – Moderate fire resistance.

🔥 Fire-Retardant GRP (FR-rated) – Complies with BS 476, ASTM E84, and EN 13501 standards for fire safety.

📌 Ensure you choose the right resin type for your fire safety requirements.

9. Lifespan & Durability of GRP Wide Flange Beams

⏳ 20+ years lifespan due to corrosion resistance, UV stability, and high mechanical strength.

10. Maintenance & Care of GRP Wide Flange Beams

🧼 Pulizia: Wash with mild detergent and water.

🔍 Ispezione: Regularly check for surface damage, especially in high-load areas.

🌞 Protezione UV: UV-resistant coatings can extend lifespan in prolonged outdoor exposure.

11. Cost of GRP Wide Flange Beams vs. Steel Beams

💰 Initial cost: Slightly higher than steel.

💰 Long-term cost: Lower due to minimal maintenance, ease of installation, and extended service life.

12. Customization Options for GRP Wide Flange Beams

📌 Available Customizations:

✅ Size & Thickness – Custom dimensions to meet project requirements.

✅ Resin Type – Fire-retardant, corrosion-resistant, or general-purpose.

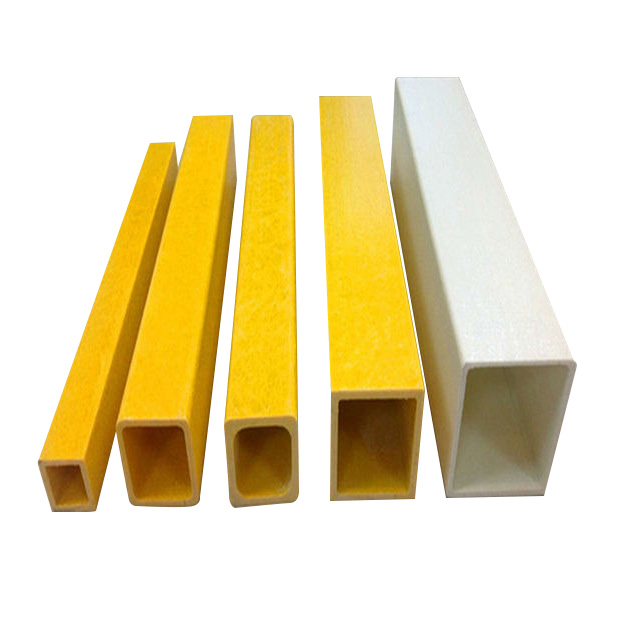

✅ Colore – Gray, green, yellow, red, black, or custom.

✅ Lunghezza – Standard lengths (3m, 6m, 12m) or cut-to-size.

13. International Standards & Certifications

GRP Wide Flange Beams comply with major industry standards, including:

✅ ISO 9001 (Quality Management)

✅ EN 13706 (Structural GRP Profiles)

✅ ASTM D4385 (Pultruded GRP Standards)

✅ BS 476 (Fire Resistance Tests)

💡 Need a quotation or technical consultation? Let me know your project details! 🚀

GRP Wide Flange Beam

Serie:

Prodotti principali >applicazione

🌉 Construction & Infrastructure – Bridges, walkways, platforms, and support structures. ⚡ Electrical & Power Industry – Structural framing for electrical enclosures. 🏗 Industrial Plants – Chemical-resistant frameworks for factories. 🌊 Marine & Offshore – Used in shipbuilding, offshore oil rigs, and seawater-exposed structures. 🏭 Chemical Plants – Structural supports in corrosive environments. 🚇 Rail & Transport – Lightweight framing and structural reinforcements.

Marchio :

TFcomposito

Nome del prodotto :

GRP Wide Flange Beam

Materiale :

Fibra di vetro

Colore :

Yellow,Gray,Other

FAQ

Q :

How strong is a GRP Wide Flange Beam compared to steel?

UN :

While GRP is not as strong as steel in absolute terms, its strength-to-weight ratio is comparable or even superior. GRP wide flange beams can support significant loads without adding excessive weight, making them ideal for lightweight structural applications.

Q :

Are GRP Wide Flange Beams fire-resistant?

UN :

🔹 Standard GRP: Moderate fire resistance. 🔹 Fire-retardant GRP (FR-GRP): Available in special formulations meeting BS 476, ASTM E84, and EN 13501 fire resistance standards. 📌 If fire resistance is a priority, use phenolic resin-based GRP for the best fire performance.

Q :

Can GRP Wide Flange Beams replace steel beams?

UN :

Yes, in many cases. GRP wide flange beams are commonly used in: ✔ Marine and offshore structures ✔ Chemical plants and corrosive environments ✔ Electrical substations (non-conductive, safe) ✔ Construction frameworks where lightweight materials are preferred 📌 However, for very high-load applications, steel may still be necessary.

Q :

How do you install a GRP Wide Flange Beam?

UN :

🛠 Cutting: Use a diamond or carbide-tipped saw. 🔩 Fastening: Use stainless steel bolts or GRP-specific adhesives. 🛠 Bonding: Structural adhesives like epoxy can provide strong joints. 📌 Tip: Wear protective gear when cutting GRP to avoid inhaling fiberglass dust.

Q :

How long do GRP Wide Flange Beams last?

UN :

⏳ Over 20 years, even in harsh conditions, due to: ✅ Corrosion resistance ✅ UV and weather protection ✅ Low maintenance requirements

Q :

Are GRP Wide Flange Beams customizable?

UN :

Yes! Customization options include: ✔ Size & thickness – Tailored dimensions available ✔ Resin type – Polyester, vinyl ester, epoxy, phenolic ✔ Fire resistance – Fire-retardant versions available ✔ Color – Gray, yellow, green, red, black, or custom ✔ Length – Standard or cut-to-size

Altri prodotti correlati