Introduzione alle prestazioni del prodotto

Steel grating is a vital component in many industrial and commercial applications, offering strength, durability, and versatile design options. Standard steel grating refers to the most common form of steel grating, used in a wide variety of sectors such as construction, transportation, industrial platforms, and stairways. Its core function is to provide safe and reliable footing, as well as ventilation, drainage, and light passage. This document will provide an in-depth look at the specifications, models, dimensions, material choices, applications, and installation considerations of standard steel grating.

1. Specifications of Standard Steel Grating

Steel grating comes in many forms and specifications. The design is primarily determined by the bar spacing, material, and intended load capacity.

1.1 Composizione del materiale

The material selection of steel grating significantly impacts its strength, durability, and resistance to environmental factors like corrosion.

-

Carbon Steel: The most common and cost-effective material used in standard steel grating. It is strong, durable, and suitable for various applications, but it requires protective coatings like galvanizing or powder coating to resist rust.

-

Stainless Steel: Stainless steel is used in applications where corrosion resistance is crucial, such as in marine environments or chemical plants. It offers enhanced longevity and strength compared to carbon steel but comes at a higher cost.

-

Galvanized Steel: Steel grating made from carbon steel that has been coated with zinc for improved corrosion resistance. Galvanizing increases the material's lifespan, particularly in outdoor environments.

-

Aluminum: Although not as strong as steel, aluminum grating is lightweight, non-corrosive, and offers good durability for applications where weight and resistance to rust are important factors.

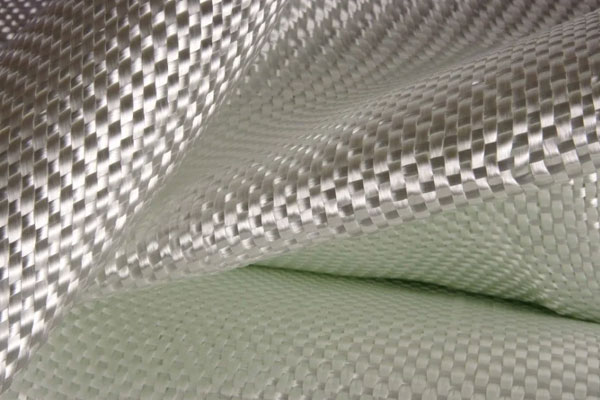

1.2 Bar Types

The design and layout of bars are central to the functionality of steel grating. The most common bar types include:

-

Flat Bars: These are commonly used in applications where a smooth, uniform surface is needed for pedestrian or vehicular traffic.

-

I-Bars: These bars have an "I" shaped cross-section and are known for their load-bearing strength, making them suitable for heavy-duty applications.

-

Rectangular Bars: Offering flexibility in spacing, rectangular bars are used for applications where specific load requirements or spacing needs must be met.

-

Serrated Bars: A serrated edge is added to flat or rectangular bars to improve traction and reduce the risk of slipping. This feature is particularly useful in high-traffic or wet environments.

1.3 Finitura superficiale

The surface finish of steel grating is crucial for both aesthetics and performance.

-

Mill Finish: A raw finish without any coating, usually applied to grating intended for indoor applications.

-

Hot-Dip Galvanized: A protective zinc coating applied to steel grating, commonly used to prevent rust and corrosion in outdoor or harsh environments.

-

Powder Coated: A layer of powdered paint is applied and baked to the surface of the grating, which offers additional protection and aesthetic value.

1.4 Capacità di carico

The load capacity of steel grating is a critical specification, particularly for industrial and commercial applications. Steel grating is designed to withstand different amounts of weight, with heavy-duty grating capable of supporting vehicles or large machinery.

-

Light Duty: Designed for pedestrian traffic or light equipment. These gratings typically have smaller bar sizes and wider spacing between bars.

-

Medium Duty: Suitable for areas with moderate foot traffic or lighter vehicular load. The bar sizes and spacing are moderate.

-

Heavy Duty: Designed for industrial applications with heavy machinery or vehicular traffic. These gratings feature larger bars and tighter spacing to handle greater weight loads.

2. Models and Types of Standard Steel Grating

Steel grating comes in various configurations to meet different functional requirements. These configurations are based on design, application, and load-bearing capacity.

2.1 Based on Load Classifications

Steel grating is categorized based on load-bearing capacity into:

-

Class A (Light Duty): Ideal for pedestrian applications like walkways, platforms, and staircases.

-

Class B (Medium Duty): Suitable for areas with medium traffic such as light-duty industrial applications and equipment platforms.

-

Class C (Heavy Duty): Used in industrial and commercial environments, including factory floors, roads, and areas with vehicular traffic.

2.2 Based on Bar Type and Arrangement

-

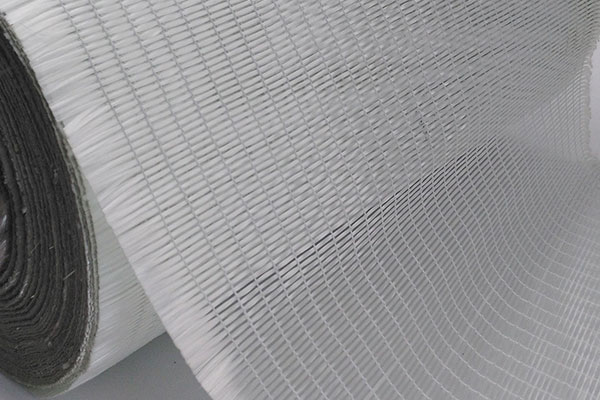

Welded Steel Grating: The most common form of steel grating, where bearing bars are welded to cross bars, providing a strong and durable structure. This type of grating is widely used in a variety of applications.

-

Swaged Steel Grating: This type of grating involves a swaging process to insert cross bars into bearing bars. It’s known for its uniform appearance and greater strength-to-weight ratio.

-

Press-Locked Steel Grating: Cross bars are pressed into bearing bars, without welding, creating a secure, mechanically locked connection. This type of grating is often used where welding could lead to material distortion.

2.3 Custom Steel Grating

Custom steel gratings are tailored to meet specific size requirements or to fit a particular load-bearing specification. For example, a custom grating may be manufactured for use in a specialized industrial facility or unique architectural design. These custom gratings may involve unique spacing, materials, or finishing.

3. Dimensions of Standard Steel Grating

Steel grating dimensions are flexible, depending on the specifications of the project. The following are common dimensions, though custom sizes are available:

3.1 Bar Dimensions

-

Bar Thickness: Typically ranges from 3 mm A 8 mm for light to heavy-duty applications.

-

Bar Height: Heights generally range from 20 mm A 50 mm, with higher bars used for heavier duty grating.

-

Bar Width: Bars are usually around 20 mm to 150 mm in width, depending on load requirements and spacing.

3.2 Panel Sizes

Standard steel grating panels typically come in sizes such as:

-

Standard Panel Size: 1,000 mm x 6,000 mm is a common size, though custom lengths and widths are available.

-

Custom Panel Sizes: Panels can be cut or fabricated to meet specific project needs, ensuring the grating fits perfectly within a designated space.

3.3 Spacing Between Bars

The spacing between bars is crucial for determining the strength, ventilation, and load distribution of the grating. Standard spacing ranges from 30 mm to 60 mm depending on the specific use, but custom spacing is available for more specialized applications.

4. Applications of Standard Steel Grating

Steel grating is used in a variety of industries and applications due to its versatility, strength, and durability.

4.1 Applicazioni industriali

-

Platform Flooring: Steel grating is often used as flooring for industrial platforms in factories and warehouses.

-

Gradini per scale: Steel grating is used in industrial staircases due to its strength and slip resistance.

-

Passerelle: Pedestrian walkways in industrial environments are often fitted with standard steel grating to prevent accidents and ensure proper drainage.

4.2 Architectural Applications

-

Building Facades: Steel grating can be used in the facade of buildings for aesthetic purposes as well as ventilation.

-

Privacy Screens: In commercial and residential applications, steel grating can be used to create privacy screens for balconies and patios.

4.3 Transportation and Infrastructure

-

Roadways: Steel grating is used in bridges, roads, and other transportation infrastructure to facilitate drainage while supporting traffic.

-

Railroad Bridges: Used for railway bridges to provide support and reduce weight while allowing water to pass through.

4.4 Safety and Security

-

Scherma: Steel grating can be used as part of fencing systems to enhance security while maintaining visibility.

-

Coperture di drenaggio: Steel grating is often used for covering drainage channels to prevent debris from entering while allowing water flow.

5. Installation Considerations

Proper installation is essential for ensuring that steel grating meets safety and performance standards.

5.1 Installation Methods

-

Welding: Common for welded steel grating to secure it in place.

-

Bolting or Clipping: Used for removable grates or where welding isn’t possible.

-

Direct Fixing: In some applications, steel grating can be directly fixed to the surface with adhesives or mechanical fasteners.

5.2 Maintenance

-

Pulizia: Regular cleaning is important to prevent debris buildup and ensure proper drainage.

-

Ispezione: Periodic inspections are needed to check for signs of wear, corrosion, or damage, especially in high-traffic areas.

Conclusione

Standard steel grating is a highly versatile material that offers an excellent combination of strength, durability, and functionality for a wide range of applications. By selecting the right material, bar arrangement, and finish, steel grating can be customized to meet the specific needs of any project, whether in industrial, commercial, or architectural settings. The dimensions and load-bearing capacities allow for a broad range of design possibilities, ensuring that steel grating remains an essential building material for decades to come.

Standard Steel Grating

Serie:

Prodotti proxy >applicazione

Building Facades: Enhances aesthetics while providing sun shading and ventilation. Parking Structures: Allows natural ventilation and prevents heat buildup. Mechanical Screens: Conceals HVAC units and mechanical equipment while ensuring airflow. Security Fencing: Offers visibility control and privacy for sensitive areas. Industrial Facilities: Provides ventilation in environments with high heat or moisture levels.

FAQ

Altri prodotti correlati