제품 성능 소개

Aluminum grating is a lightweight yet strong solution used for industrial, commercial, and architectural applications. Its inherent resistance to corrosion, durability, and ease of installation make it an ideal choice for environments where weight reduction, longevity, and aesthetics are critical.

Key Features of Aluminum Grating

-

경량:

- Aluminum is significantly lighter than steel, making it easier to handle and install.

-

부식 저항:

- Naturally resistant to rust and corrosion, even in marine or chemical environments.

-

Strength-to-Weight Ratio:

- Provides excellent load-bearing capacity while minimizing weight.

-

사용자 정의 가능:

- Available in various sizes, patterns, and finishes for specific applications.

-

스파크 방지:

- Ideal for environments where sparking could pose a hazard, such as oil refineries or chemical plants.

-

미적 매력:

- Its sleek, modern appearance makes it popular in architectural applications.

Specifications of Aluminum Grating

1. Materials

- Made from high-grade aluminum alloys such as:

- 6063-T6: Known for excellent corrosion resistance and strength.

- 6061-T6: Provides superior strength and toughness.

2. Types of Aluminum Grating

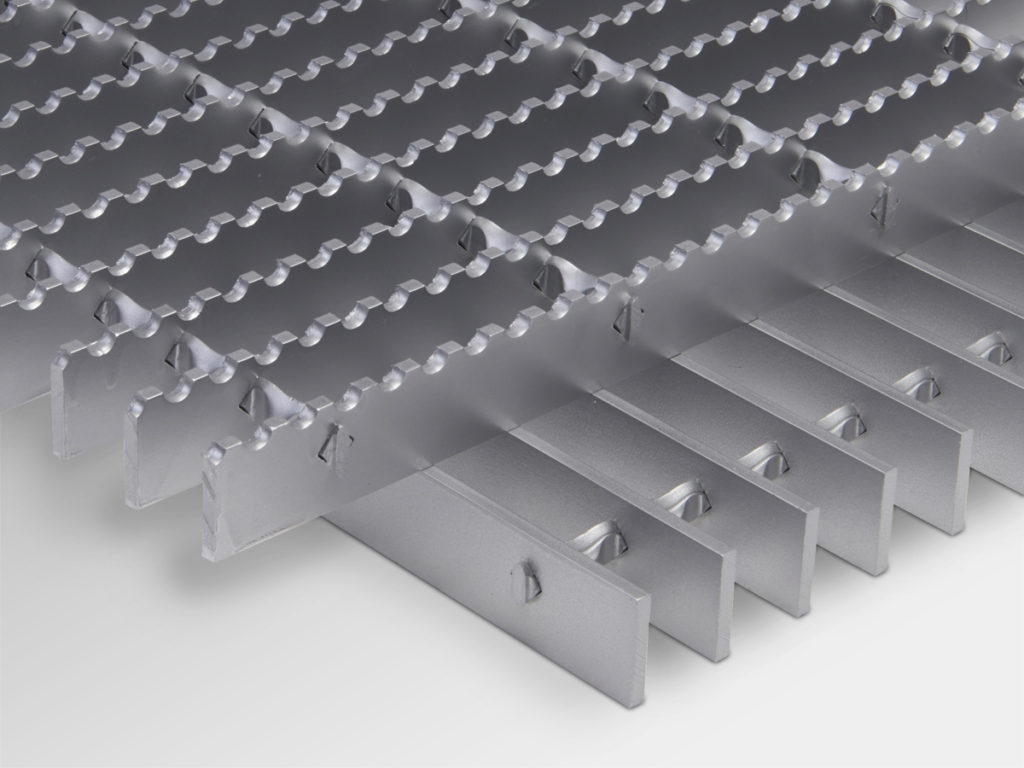

- Swaged Aluminum Grating:

- Crossbars are permanently locked to bearing bars using a swaging process, resulting in a rigid, durable panel.

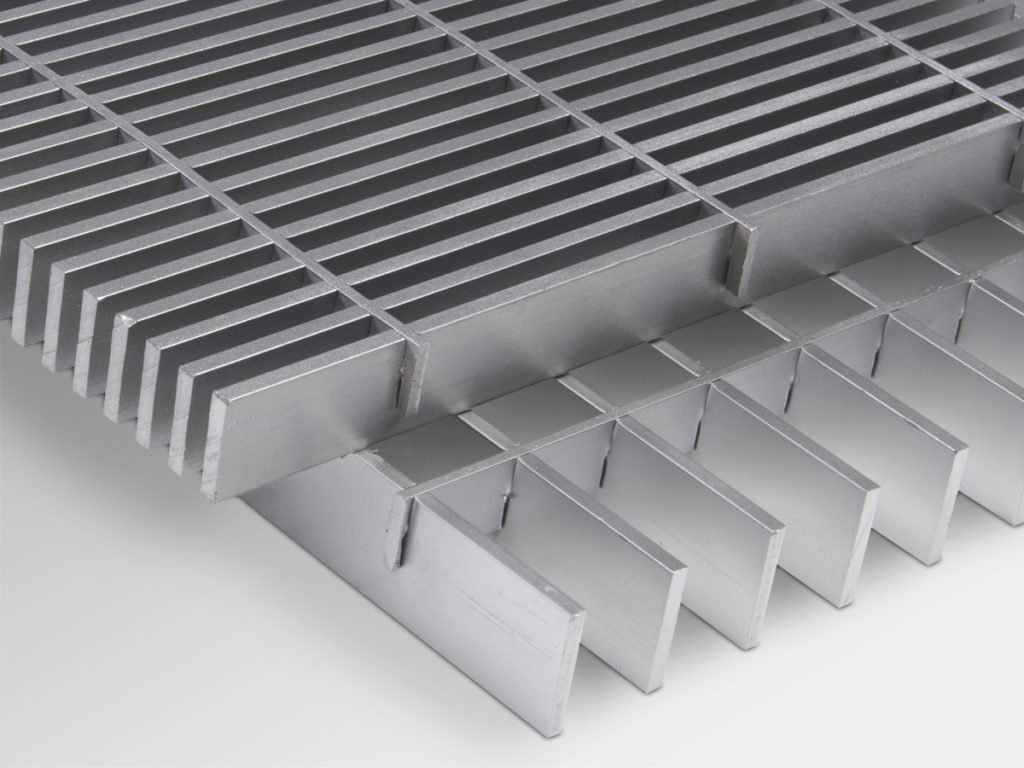

- Press-Locked Aluminum Grating:

- Bearing and crossbars are pressed together under pressure, creating a smooth, clean surface.

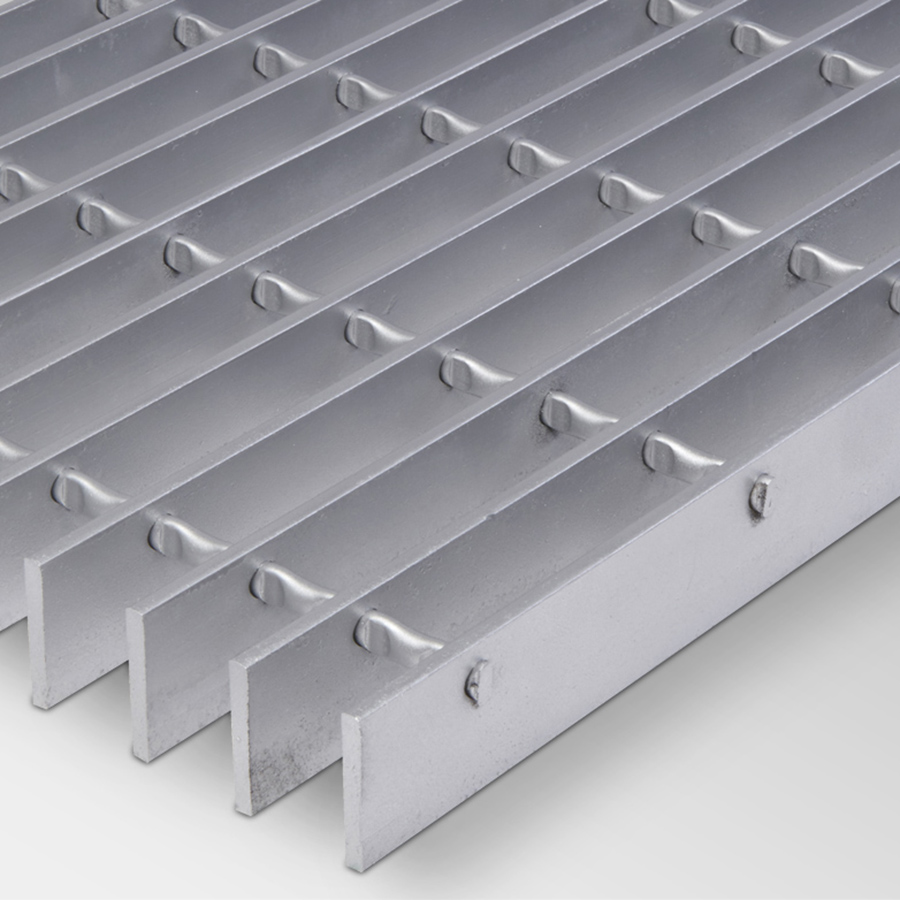

- Riveted Aluminum Grating:

- Crossbars are riveted to bearing bars, offering exceptional strength for heavy loads.

- Expanded Aluminum Grating:

- A single aluminum sheet cut and stretched into a diamond-shaped mesh, providing lightweight and cost-effective solutions.

3. Dimensions

- Bearing Bar Size:

- 두께: 3/16 inch (4.8 mm) 에게 1/4 inch (6.35 mm).

- 깊이: 1 inch (25.4 mm) 에게 4 inches (101.6 mm).

- Spacing:

- Standard bearing bar spacing: 7/16 inch (11.1 mm), 1/2 inch (12.7 mm), 또는 1 inch (25.4 mm).

- Crossbar spacing: Typically 4 inches (101.6 mm) 또는 6 inches (152.4 mm).

4. Load Ratings

- Load capacities depend on bearing bar size, depth, and spacing. Aluminum grating is typically designed to support pedestrian traffic and light-to-moderate vehicle loads.

5. Finishes

- Mill Finish:

- Natural aluminum surface, suitable for indoor or low-corrosion environments.

- Anodized:

- Provides enhanced corrosion resistance and aesthetics, available in various colors.

- Powder-Coated:

- Adds a layer of durability and visual appeal, with customizable color options.

6. Surface Options

- Plain Surface:

- Smooth for general use; suitable for non-hazardous environments.

- Serrated Surface:

- Offers slip resistance, ideal for wet, oily, or icy conditions.

7. Compliance Standards

- Meets industry standards such as:

- NAAMM MBG 531: Guidelines for bar grating performance.

- ASTM B221: Specifications for aluminum alloy extruded bars.

Manufacturing Processes

- Extrusion:

- Aluminum is extruded into bearing and crossbars with precise dimensions.

- Swaging:

- Crossbars are swaged into bearing bars for a secure and rigid fit.

- Press-Locking:

- Bearing and crossbars are mechanically locked under pressure.

- Anodizing or Coating:

- Surface treatments are applied to enhance durability and aesthetics.

Applications of Aluminum Grating

-

산업용 플랫폼:

- Lightweight and corrosion-resistant grating for chemical plants, refineries, and marine environments.

-

Walkways and Catwalks:

- Commonly used in areas where lightweight materials are preferred, such as oil rigs and processing plants.

-

Architectural Design:

- Aesthetic grating for facades, sunscreens, and decorative elements in modern buildings.

-

해양 응용:

- Ideal for docks, ship decks, and offshore platforms due to its resistance to saltwater corrosion.

-

계단 보행:

- Pre-fabricated treads for indoor or outdoor stairs with slip-resistant surfaces.

-

배수 커버:

- Open design allows water and debris to pass through, making it suitable for drainage systems.

-

HVAC Platforms:

- Durable and lightweight grating for access platforms in HVAC systems.

Advantages of Aluminum Grating

- 부식 저항: Suitable for harsh environments, including chemical and marine settings.

- 내구성: Long-lasting with minimal maintenance.

- Eco-Friendly: Aluminum is 100% recyclable, making it an environmentally responsible choice.

- 쉬운 설치: Lightweight nature reduces handling and installation costs.

- 사용자 정의 가능: Available in various sizes, patterns, and finishes to meet specific project requirements.

Installation Guidelines

-

Preparation:

- Ensure proper support structure with adequate spacing for grating panels.

- Verify measurements and alignment before installation.

-

Fastening:

- Use clips, bolts, or welding to secure the grating to the supporting structure.

- Non-corrosive fasteners are recommended, especially for outdoor or marine applications.

-

Alignment:

- Align panels to ensure uniform load distribution and aesthetic consistency.

-

점검:

- Check for sharp edges, burrs, or surface imperfections that could affect safety during installation.

Maintenance Tips

- Regular Cleaning:

- Remove dirt, debris, and chemical residues to maintain surface integrity and appearance.

- 점검:

- Periodically inspect for signs of wear or damage, especially in high-traffic areas.

- Coating Maintenance:

- Touch up or reapply finishes as needed to maintain corrosion resistance and aesthetics.

결론

Aluminum grating is a versatile, lightweight, and corrosion-resistant solution suitable for a wide range of applications, from industrial platforms to architectural designs. Its strength-to-weight ratio, durability, and aesthetic appeal make it a preferred choice for projects where performance and appearance matter. By selecting the appropriate type, dimensions, and finishes, aluminum grating ensures safety, functionality, and long-term value for any application.

기타 관련 제품