FRP (Fiberglass Reinforced Plastic) fermentation tanks are corrosion-resistant, lightweight, and highly durable vessels designed for microbial fermentation processes in industries such as pharmaceuticals, food and beverage, agriculture, chemical processing, and biofuel production. These tanks are engineered using advanced composite technology, combining a chemical-resistant inner lining with high-strength fiberglass reinforcement to create a sanitary, thermally stable, and long-lasting vessel capable of withstanding both biological and chemical agents.

제품 성능 소개

As the demand for cost-effective, long-life fermentation vessels increases, FRP fermentation tanks have become a preferred alternative to traditional stainless steel and carbon steel tanks, especially where chemical or pH exposure is a concern.

주요 특징들

-

Chemical & Corrosion Resistance: Excellent resistance to organic acids, bases, solvents, and disinfectants used in cleaning (CIP/SIP systems).

-

Thermal Stability: Maintains mechanical integrity under fermentation temperatures up to 120°C depending on resin system.

-

Sanitary Inner Surface: Smooth, non-porous, food-safe inner liner prevents contamination, easy to clean and sterilize.

-

Customizable Configurations: Built in vertical or horizontal form, with options for conical bottoms, heating/cooling jackets, agitators, and nozzles.

-

Lightweight & High Strength: Easy transportation and installation, especially for large-scale tanks.

-

비용 효율적: Lower lifecycle cost compared to metal fermentation tanks due to corrosion resistance and minimal maintenance.

애플리케이션

FRP fermentation tanks are suitable for aerobic and anaerobic fermentation processes in:

-

Pharmaceutical Industry: Antibiotics, insulin, enzymes, and probiotics.

-

Food & Beverage Industry: Yogurt, kombucha, vinegar, beer, wine, soy sauce, pickles, and kimchi.

-

Agriculture: Animal feed fermentation, silage, and biofertilizer production.

-

Biotechnology: Bioethanol, biogas, bioplastics, algae, and microbial biomass production.

-

폐수 처리: Anaerobic digestion for methane production.

-

Distilleries: Alcohol and spirit fermentation using molasses, grains, or fruits.

Construction & Materials

FRP fermentation tanks are fabricated through either filament winding, hand lay-up, 또는 vacuum infusion, using corrosion-resistant thermosetting resins and high-strength fiberglass.

1. Inner Liner (Corrosion Barrier)

| Liner Type | 설명 |

|---|---|

| 비닐 에스테르 수지 | Used for high chemical and thermal resistance; suitable for aggressive fermentation substrates. |

| 이소프탈산 폴리에스터 수지 | Cost-effective, general-purpose food-safe applications. |

| FDA-Approved Resin | Food-grade certified liners for direct contact with consumables. |

| Antimicrobial Coating (Optional) | Prevents microbial growth on the surface, reducing contamination risk. |

2. Structural Layer

-

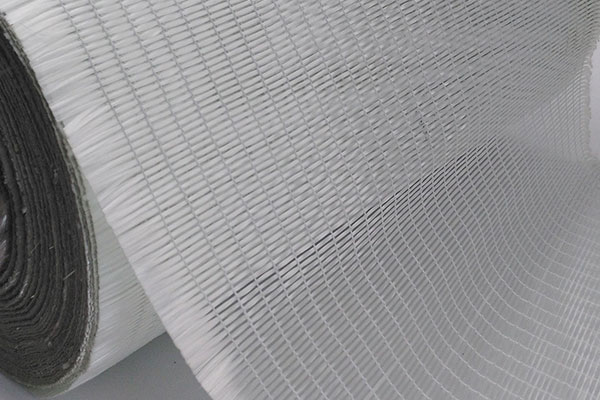

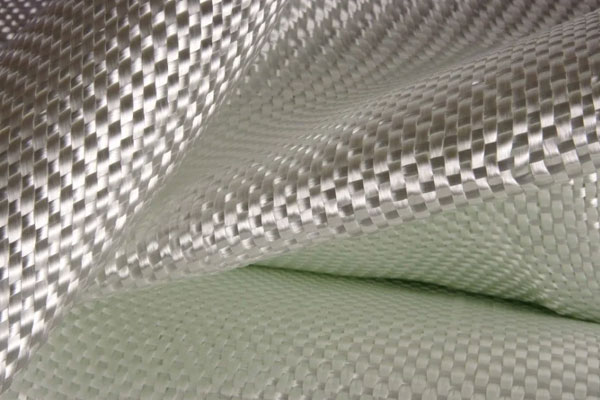

Reinforced with 다진 스트랜드 매트, woven roving, 또는 filament-wound continuous fibers.

-

Optimized laminate schedule for hoop and axial strength, especially for tall vertical tanks.

3. External Finish

-

Gelcoat Layer: UV-resistant coating for outdoor exposure.

-

색상 옵션: Grey, white, green, blue, or custom colors.

-

열 절연: Optional PU foam or rockwool jacketing for temperature-sensitive fermentation.

Design Configurations

| 모수 | Options |

|---|---|

| Shape | Vertical cylindrical, horizontal, conical bottom, flat bottom |

| Volume Range | 500 L – 300,000+ L |

| Tank Mounting | Skirt support, leg support, saddle-mounted (horizontal) |

| Agitation | Top-entry or side-entry agitators for aerobic mixing |

| Jacketed Systems | External coil or full-wall jacket for heating/cooling |

| Manway Access | Top manhole, side manhole, sanitary clamps |

| Instrumentation | pH sensor ports, temperature probes, sight glasses, CIP nozzles |

| Accessories | Breather valves, vent filters, level indicators, overflow outlets |

Sanitation & Sterility

-

Smooth inner surface with resin-rich liner prevents microbial buildup.

-

CIP/SIP Ready: Compatible with steam-in-place and clean-in-place systems.

-

Antimicrobial liners optional for high-purity applications.

Thermal Performance

-

Operating temperature range: -40°C to 120°C (resin-dependent)

-

Insulated versions maintain fermentation temperatures with minimal energy loss.

-

Optional thermal jackets (glycol or steam) support temperature control.

Technical Data Sheet (TDS)

기계적 성질

| 재산 | Typical Value | Test Standard |

|---|---|---|

| 인장강도 | 120–200 MPa | ASTM D638 |

| 굽힘 강도 | 180–300 MPa | ASTM D790 |

| 압축 강도 | 150–250 MPa | ASTM D695 |

| Modulus of Elasticity | 7,000–12,000 MPa | ASTM D790 |

| 충격 저항 | >100 J/m | ASTM D256 |

| 바콜 경도 | 40–50 | ASTM D2583 |

열적 특성

| 재산 | 값 |

|---|---|

| Max Operating Temperature (Vinyl Ester) | 110–120°C |

| Max Operating Temperature (Polyester) | 65–70°C |

| Thermal Conductivity | 0.3–0.5 W/mK |

| 열팽창 계수 | 2.5 × 10⁻⁵ /°C |

Chemical Resistance (Common Substances in Fermentation)

| Chemical/Substance | Resistance Rating |

|---|---|

| Lactic Acid | 훌륭한 |

| Ethanol (95%) | 훌륭한 |

| Acetic Acid | 훌륭한 |

| Citric Acid | 훌륭한 |

| Yeast Extract | 훌륭한 |

| Sodium Hydroxide (2–5%) | 훌륭한 |

| Hydrogen Peroxide (3%) | 좋은 |

| Ammonia | 좋은 |

| Phosphoric Acid | 좋은 |

| Cleaning Detergents | 훌륭한 |

Sanitation Properties

-

Inner surface finish: ≤ 0.5 μm (sanitary polish)

-

FDA/USDA compliance available

-

CIP/SIP tested (steam up to 121°C for 30 minutes)

Standards & Certifications

-

ASME RTP-1: For reinforced thermoset plastic vessels

-

ASTM D3299 / D4097: Filament-wound and contact-molded tanks

-

ISO 9001:2015: Quality management compliance

-

NSF/ANSI 61: Drinking water and food-grade compliance (optional)

-

FDA 21 CFR 177.2420: Food contact resin compliance

Advantages of FRP Over Stainless Steel Tanks

| 특징 | FRP Tank | Stainless Steel Tank |

|---|---|---|

| 부식 저항 | 훌륭한 | Prone to corrosion with acids/alkalis |

| 무게 | 경량 | Heavy |

| 비용 | 낮추다 | High initial & maintenance cost |

| Customizability | 높은 | Medium |

| 열 절연 | Built-in options | External insulation required |

| Maintenance | Minimal | Frequent cleaning required |

| Lead Time | Shorter | Longer |

Installation Guidelines

-

Foundation: Concrete slab or steel platform with level surface

-

Hoisting: Use built-in lifting lugs or straps; avoid side pressure

-

Anchoring: For outdoor or seismic zones, anchor to resist uplift

-

사이: Flexible couplings recommended to allow for thermal expansion

-

테스트: Hydrostatic leak testing prior to commissioning

Maintenance Tips

-

Inspect tank internals annually for wear or damage

-

Sanitize before and after each fermentation cycle

-

Use non-abrasive CIP solutions

-

Check gaskets, seals, and nozzles for cracks or buildup

Optional Upgrades

-

Stainless steel or HDPE nozzles

-

Anti-foam spray rings

-

External viewing windows

-

Agitator with VFD controller

-

PLC control system for real-time fermentation monitoring

-

Flame arrestors for alcohol fermentation

Customization Capabilities

We offer full customization:

-

Volume: 0.5 m³ – 300 m³

-

Geometry: Cylindrical, rectangular, squat-type

-

Port arrangements: Top, bottom, side

-

Heating/cooling: Coils, jackets, electric pads

-

Certifications: CE, ISO, NSF, FDA, ATEX (on request)

FRP (Fiberglass Reinforced Plastic) fermentation tanks

시리즈 :

프록시 제품 >애플리케이션

Pharmaceutical Industry: Antibiotics, insulin, enzymes, and probiotics. Food & Beverage Industry: Yogurt, kombucha, vinegar, beer, wine, soy sauce, pickles, and kimchi. Agriculture: Animal feed fermentation, silage, and biofertilizer production. Biotechnology: Bioethanol, biogas, bioplastics, algae, and microbial biomass production. Wastewater Treatment: Anaerobic digestion for methane production. Distilleries: Alcohol and spirit fermentation using molasses, grains, or fruits.

재료 :

FRP

유형 :

FRP (Fiberglass Reinforced Plastic) fermentation tanks

자주하는 질문

질문 :

What are the advantages of using FRP tanks for fermentation?

ㅏ :

Excellent corrosion and chemical resistance Lower cost than stainless steel tanks Lightweight and easier to transport/install Long service life (15–30 years) Customizable shapes, volumes, and connections Compatible with CIP/SIP systems for sanitation

질문 :

Are FRP tanks food-grade and safe for consumables?

ㅏ :

Yes. When manufactured with FDA-approved resins or NSF 61-certified linings, FRP fermentation tanks are 100% food-safe and suitable for direct contact with food or beverages like yogurt, beer, wine, soy sauce, and vinegar.

질문 :

What resin is best for fermentation tanks?

ㅏ :

Vinyl Ester Resin: For strong chemical resistance (e.g. acidic fermentation) Isophthalic Polyester Resin: For general food applications Bisphenol A (Epoxy-based): For high-temperature resistance FDA and antimicrobial-grade resin options are available

질문 :

What volumes are available?

ㅏ :

Small-scale: 500 L – 5,000 L Medium-scale: 10,000 L – 50,000 L Large-scale: 100,000 L – 300,000+ L All volumes can be customized according to your process needs.

질문 :

Can FRP fermentation tanks be used outdoors?

ㅏ :

Yes. FRP tanks can be designed with UV-resistant gelcoats and weatherproof exteriors for long-term outdoor use. Optional insulation and thermal jackets are available to stabilize temperature in fluctuating environments.

질문 :

What temperature ranges can FRP tanks withstand?

ㅏ :

Standard FRP tanks: up to 70°C (polyester) High-performance tanks (vinyl ester): up to 120°C Optional: thermal insulation and glycol/stainless steel jacketed systems

질문 :

How do I clean or sterilize an FRP fermentation tank?

ㅏ :

FRP tanks support CIP (Clean-in-Place) and SIP (Steam-in-Place) processes: Use mild alkaline/acidic solutions and warm water Max steam temperature: 121°C for 30 minutes (with high-temp resin) Smooth internal surface prevents bacterial buildup

기타 관련 제품