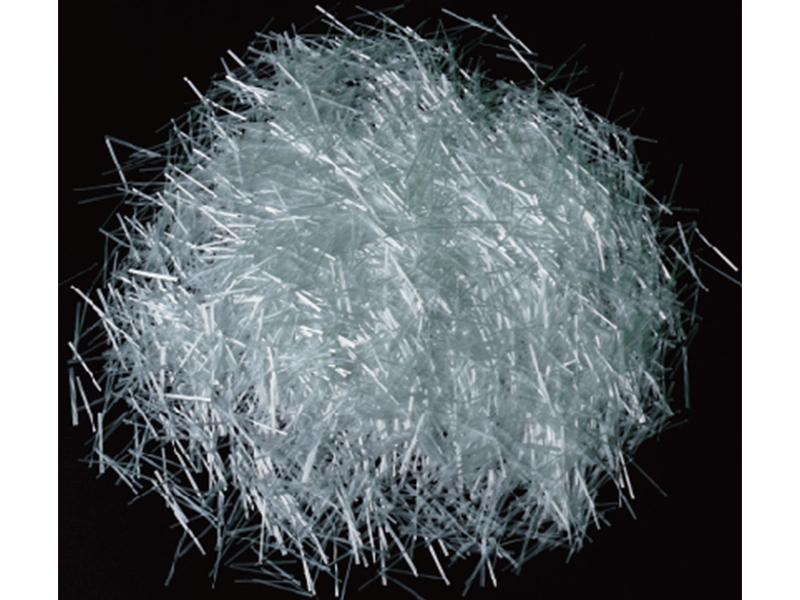

SMC Roving refers to a type of chopped strand fiberglass roving specifically engineered for use in the Sheet Molding Compound (SMC) process — a high-volume method of producing fiber-reinforced plastic (FRP) parts. The SMC process is commonly used to manufacture automotive body panels, electrical enclosures, bathroom fixtures, and industrial housings.

제품 성능 소개

SMC rovings are continuous glass fiber strands that are chopped and distributed uniformly in a resin paste to create semi-finished sheets. These sheets are then compression molded into complex components.

The selection of SMC roving is critical to ensuring the processability, mechanical properties, and surface finish of the final product. SMC roving must offer excellent chop ability, low static, uniform dispersion, good wet-out, and high compatibility with the resin matrix.

2. SMC Process Overview

The SMC process involves four major steps:

-

Compounding: SMC roving is chopped and spread onto a resin paste layer on a carrier film. A top film covers it, and the sheet is compacted to the desired thickness.

-

Maturation: The SMC sheet is rolled and aged (typically 24–72 hours) to increase its viscosity and molding consistency.

-

조형: Pre-cut sheets are placed into a heated compression mold and cured under pressure.

-

Demolding: After a brief cure cycle, the molded part is removed, trimmed, and finished as needed.

3. Key Features of SMC Roving

-

Excellent Chop Ability: Clean and consistent chopping with minimal fuzzing.

-

Rapid Wet-Out: Ensures efficient resin impregnation during sheet formation.

-

Strand Integrity: Maintains structural performance during mixing and compaction.

-

Low Static: Prevents fly and strand tangling, ensuring clean sheet surfaces.

-

Consistent Fiber Length Distribution: Critical for uniform mechanical performance in molded parts.

-

Compatible Sizing: Ensures chemical bonding with polyester or vinyl ester resins.

-

High Strength Retention: Enables strong, lightweight final components.

-

표면 마감: Helps in achieving Class A surface finishes for visible applications.

4. Applications of SMC Roving

4.1 Automotive

-

Hoods, trunk lids, roof panels

-

Structural supports, underbody shields

-

EV battery enclosures

4.2 Electrical & Energy

-

Transformer housings

-

Meter boxes

-

Cable trays

4.3 Sanitary Ware

-

Bathtubs, shower trays

-

Washbasin stands

-

Composite toilet seats

4.4 Construction & Infrastructure

-

Utility poles

-

Manhole covers

-

Decorative architectural panels

4.5 Industrial Equipment

-

Machine guards

-

Pump housings

-

Control panel boxes

5. Technical Requirements for SMC Roving

For optimal performance, SMC roving must meet several process-specific criteria:

| Requirement | 설명 |

|---|---|

| Tex or Yield | Typically 2400, 4800, 9600 tex. Heavier tex may be used for structural SMC. |

| Moisture Content | <0.10% to avoid porosity during molding. |

| Size Content | 1.2% – 2.0% depending on resin system. |

| Strand Count | Even strand distribution is critical to prevent defects. |

| 절단 가능성 | Clean cut with little to no fly, fuzz, or static. |

| Wet-Out Time | Fast wet-out for homogenous paste absorption. |

| Storage Stability | Good shelf life under recommended conditions. |

6. Technical Data Sheet (TDS)

제품 이름: SMC Roving

Glass Type: E-glass (Electrical grade)

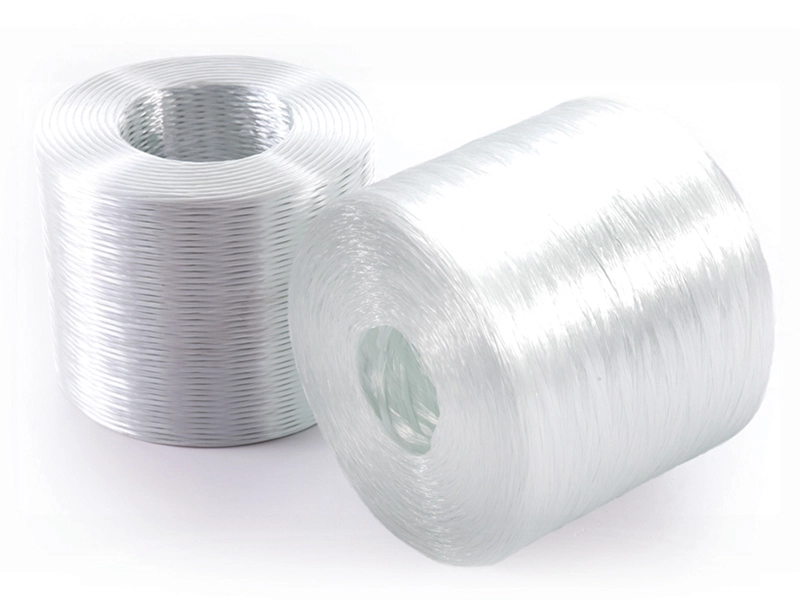

Product Form: Continuous strand roving on paper tube

Available Tex Sizes: 2400 / 4800 / 9600 tex

6.1 Physical and Chemical Properties

| 재산 | Typical Value | 시험 방법 |

|---|---|---|

| 필라멘트 직경 | 13–24 µm | ISO 1888 |

| Linear Density (Tex) | 2400 / 4800 / 9600 | ISO 1889 |

| Moisture Content (%) | ≤ 0.10 | ISO 3344 |

| Size Content (%) | 1.2 – 2.0 | ISO 1887 |

| Loss on Ignition (%) | 1.5 ± 0.2 | ISO 1887 |

| Sizing Compatibility | Polyester, Vinyl Ester, Epoxy | Internal Standards |

| Chop Performance | Excellent (Clean, minimal fuzz) | Internal Method |

| Static Buildup | Negligible | Observation/Rating |

6.2 Mechanical Properties (In Composite Form)

| 재산 | Typical Value | 시험 방법 |

|---|---|---|

| 인장강도 | > 2000 MPa | ASTM D638 |

| 굽힘 강도 | > 1000 MPa | ASTM D790 |

| 굽힘 탄성률 | > 20 GPa | ASTM D790 |

| 충격 강도 (노치) | > 80 kJ/m² | ISO 179 |

| 밀도 | 1.9 – 2.1 g/cm³ | ASTM D792 |

| Elongation at Break | 2.2 – 3.0% | ASTM D638 |

| Surface Quality | Class A finish possible | Visual ASTM D2563 |

7. Packaging and Labeling

포장

-

Wound on cylindrical paper tubes (3-inch diameter core)

-

Rolls weight: ~15–25 kg each (varies by tex)

-

Packed in individual PE bags, then stacked on pallets

-

Pallet size: 1.1m x 1.1m; 48–64 rolls per pallet

-

Pallet stretch-wrapped for stability and protection

Labeling

Each roll is labeled with:

-

Product name and grade

-

Tex/yield

-

순중량

-

Batch number

-

Production date

-

Manufacturer and handling instructions

8. Storage and Shelf Life

-

Store in a cool, dry, and well-ventilated warehouse

-

Ideal temperature: 15–35°C

-

Relative humidity: ≤ 65%

-

Keep sealed in original packaging until use

-

Avoid direct sunlight or high-moisture environments

Shelf Life: 12 months from production date under standard storage conditions.

9. Handling and Processing Guidelines

-

Unwinding: Use creel systems designed for even tension distribution.

-

Chopping: Ensure blades are sharp and clean to minimize fuzz.

-

Sheet Formation: Maintain even resin flow and fiber dispersion during compounding.

-

Maturation: Allow proper aging time to stabilize viscosity.

-

Compression Molding: Match mold temperatures to resin cure characteristics; control cycle times carefully.

10. Health and Safety

Hazards

SMC roving is non-toxic but can cause mechanical irritation to skin, eyes, and lungs during processing.

Protective Measures

-

Wear gloves, goggles, and masks when handling

-

Use dust extraction systems in high-volume processing areas

-

Wash skin with soap and water after contact

First Aid

-

Eyes: Flush with water for 15 minutes

-

Skin: Rinse and apply moisturizer

-

Inhalation: Move to fresh air

Refer to the Material Safety Data Sheet (MSDS) for more details.

11. Quality Assurance and Standards

SMC rovings are typically certified to the following quality and compliance standards:

-

ISO 9001: Quality Management Systems

-

ISO 14001: Environmental Management

-

REACH and RoHS Compliance

-

UL, ASTM, or DIN Certifications (on request)

Routine QC checks include:

-

Moisture and size content analysis

-

Tensile testing

-

Choppability testing

-

Resin compatibility checks

12. Product Customization and Support

Leading manufacturers offer customization services including:

-

Tex range adjustments

-

Special sizing for unique resin systems

-

Surface treatment options

-

Pallet optimization for specific production lines

Technical Support Services Include:

-

On-site testing and troubleshooting

-

Process optimization

-

Composite design consulting

-

Mold flow simulation

13. Environmental Impact

-

Recyclability: Glass fiber scrap from SMC can be reused in filler-grade applications

-

지속 가능성: E-glass is non-toxic and chemically inert

-

Compliance: Products meet global environmental regulations including RoHS, REACH, and Proposition 65

14. Conclusion

SMC roving is a high-performance fiberglass reinforcement product designed for the production of sheet molding compounds used across a wide array of industries. With its balance of excellent processability, mechanical strength, and surface finish potential, it enables manufacturers to produce lightweight, corrosion-resistant, and structurally sound components with repeatable quality.

SMC Roving

시리즈 :

유리 섬유 조립 로빙 >애플리케이션

자동차 / 소비재 및 업무용 장비 / 스포츠 및 레저 / 전기전자 / 건축 및 건설 / 인프라

유리 종류 :

이자형

상품명 :

SMC Roving

자주하는 질문

질문 :

공장이세요? 당신은 어디 어디에 있습니까?

ㅏ :

우리는 FRP 격자 및 인발 성형 프로파일 제조업체, FRP 원사 재료 상인입니다. 우리는 중국 Jushi Co.의 최대 유통업체입니다. 또한 여러 FRP 원사 제조업체의 제품을 판매합니다. 우리는 중국 안후이에 있습니다.

질문 :

문의 시 어떤 정보를 추천하시나요?

ㅏ :

1. 어떤 텍스트가 필요합니까? 2. 어떤 용도로 사용하시나요? 아니면 기술이 직조, 인발 또는 와인딩입니까? 3. 수량은 얼마나 필요합니까? 4. 어떤 레진을 조합하나요? 폴리에스터 수지인가, 에폭시 수지인가? 5. FOB 또는 CIF 가격이 필요합니까? CIF인 경우 포트를 알려주십시오.

질문 :

MOQ는 무엇입니까?

ㅏ :

보통 1톤

질문 :

패키지 및 배송

ㅏ :

일반 패키지: 판지(단위 가격에 포함됨) 특수 패키지: 실제 상황에 따라 충전해야 합니다. 일반 배송: 귀하가 지정한 화물 운송.

질문 :

언제 제안할 수 있습니까?

ㅏ :

우리는 일반적으로 귀하의 문의를 받은 후 24시간 이내에 인용합니다. 당신이 가격을 얻기 위해 매우 긴급한 경우 pls는 저희에게 전화하거나 귀하의 이메일로 알려주십시오. 그래야 우리가 당신에게 우선 순위를 회신할 수 있습니다.

질문 :

샘플 비용은 어떻게 청구하나요?

ㅏ :

당사 재고에서 샘플이 필요한 경우 무료로 제공할 수 있지만 운임을 지불해야 합니다. 특별한 크기가 필요한 경우 주문할 때 환불 가능한 샘플 제작 수수료를 청구합니다.

질문 :

생산을 위한 당신의 배달 시간은 무엇입니까?

ㅏ :

재고가 있는 경우 7일 이내에 배송할 수 있습니다. 재고가 없는 경우 7~15일 소요됩니다!

기타 관련 제품