FRP EZ Angle is a lightweight, high-strength, and corrosion-resistant composite structural component designed for a variety of construction, industrial, and infrastructure applications. Manufactured using fiber-reinforced plastic (FRP) technology, EZ Angle provides an excellent alternative to traditional materials like steel, aluminum, and wood. It is widely used for framing, support structures, reinforcement, and quick assembly solutions due to its ease of installation and long-lasting durability.

제품 성능 소개

This detailed product description covers physical properties, specifications, advantages, disadvantages, and applications ~의 FRP EZ Angle.

1. Physical Properties of FRP EZ Angle

FRP EZ Angle is made from a combination of high-performance glass fibers and a polymer resin matrix, providing exceptional mechanical, chemical, and thermal properties.

1.1. Strength and Durability

-

높은 강도 대 중량비 – Stronger than wood and comparable to steel, but much lighter.

-

Flexural and Tensile Strength – Resists bending and pulling forces without deformation.

-

충격 저항 – Can withstand mechanical shocks and vibrations without cracking.

1.2. Corrosion and Weather Resistance

-

Non-Corrosive – Unlike steel, FRP EZ Angle does not rust, corrode, or degrade when exposed to moisture or chemicals.

-

Resistant to UV Radiation – Formulated with UV-resistant coatings to prevent fading and degradation from prolonged sun exposure.

-

Chemical Stability – Withstands exposure to harsh chemicals, acids, and alkalis, making it ideal for industrial environments.

1.3. Electrical and Thermal Properties

-

비전도성 – Does not conduct electricity, making it safe for electrical and telecommunications applications.

-

열 절연 – Has low thermal conductivity, reducing heat transfer and making it energy efficient.

1.4. Fire Resistance

-

Available in Fire-Retardant Formulations – Meets industry fire safety standards when using fire-retardant resins.

-

Low Smoke and Toxicity – Some versions produce minimal smoke and toxic emissions in the event of a fire.

2. Specifications and Dimensions

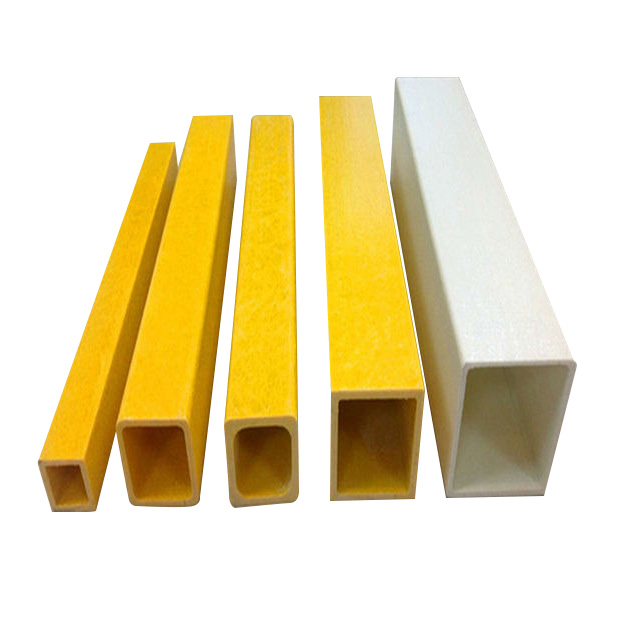

FRP EZ Angle is available in various sizes, thicknesses, and configurations to accommodate different project requirements.

2.1. Standard Dimensions

-

Leg Lengths: Typically ranges from 25 mm × 25 mm (1” × 1”) 에게 150 mm × 150 mm (6” × 6”)

-

두께: Ranges from 3 mm (1/8”) to 12 mm (1/2”)

-

길이: Standard lengths include 3 meters (10 feet) and 6 meters (20 feet), with custom lengths available upon request.

2.2. Material Composition

-

Fibers: E-glass (most common), S-glass (for higher strength), or carbon fiber (for specialty applications).

-

Resins:

-

폴리에스테르 – General-purpose, cost-effective, and durable.

-

비닐 에스테르 – Superior chemical and corrosion resistance.

-

Epoxy – Best mechanical performance and high durability.

-

페놀 – Fire-resistant and low smoke emission for high-temperature applications.

-

2.3. Mechanical Properties (Typical Values)

| 재산 | Typical Value |

|---|---|

| 인장강도 | 200-600 MPa |

| 굽힘 강도 | 200-500 MPa |

| 압축 강도 | 200-550 MPa |

| 밀도 | 1.5-2.0 g/cm³ |

| Modulus of Elasticity | 20-35 GPa |

3. Advantages of FRP EZ Angle

FRP EZ Angle offers several advantages over traditional construction materials, making it a preferred choice for many industries.

3.1. Lightweight and Easy to Handle

-

70% lighter than steel 그리고 30% lighter than aluminum, making transportation and installation easier.

-

Requires fewer workers and minimal lifting equipment during installation.

3.2. Corrosion Resistance for Harsh Environments

-

No rusting, rotting, or degradation when exposed to water, chemicals, or industrial gases.

-

Ideal for marine, industrial, and outdoor applications where metal structures would deteriorate quickly.

3.3. Electrical and Magnetic Safety

-

Completely non-conductive, making it safe for use in power stations, electrical substations, and MRI facilities.

-

Non-magnetic, making it ideal for sensitive electronic and medical equipment environments.

3.4. Low Maintenance and Long Service Life

-

No need for painting, galvanizing, or protective coatings, reducing maintenance costs.

-

Resistant to biological degradation, such as mold, termites, and fungal growth.

3.5. Simple Fabrication and Installation

-

Easily cut, drilled, and assembled with standard tools.

-

No welding is required, eliminating the need for hot work permits and reducing installation risks.

3.6. Sustainability and Cost Savings

-

Longer lifespan than traditional materials, resulting in lower replacement costs over time.

-

No need for expensive coatings or anti-corrosion treatments, saving money on maintenance.

4. Disadvantages of FRP EZ Angle

Despite its many benefits, FRP EZ Angle has some drawbacks that should be considered.

4.1. Higher Initial Cost

-

More expensive than traditional materials like steel and aluminum on a per-unit basis.

-

However, reduced maintenance and longer lifespan can offset the initial investment.

4.2. Lower Stiffness Compared to Steel

-

More flexible than steel, which may require additional support in load-bearing applications.

-

Not always suitable for high-stress structural applications unless properly engineered.

4.3. UV Degradation Without Protection

-

Prolonged exposure to direct sunlight can cause color fading and surface degradation.

-

Requires UV-resistant coatings for long-term outdoor applications.

4.4. Limited High-Temperature Resistance

-

Standard FRP softens above 150-200°C, whereas metals can withstand much higher temperatures.

-

Fire-resistant formulations are available but may come at a higher cost.

4.5. Recycling Challenges

-

Difficult to recycle due to the composite nature of FRP materials.

-

Disposal options are limited, though some companies offer specialized composite recycling services.

5. Applications of FRP EZ Angle

FRP EZ Angle is widely used in various industries due to its unique properties.

5.1. Industrial Applications

-

화학공장 – Corrosion-resistant structural supports for chemical processing equipment.

-

Water and Wastewater Treatment Plants – Used in walkways, platforms, and handrails exposed to moisture and chemicals.

5.2. Marine and Offshore

-

Dock and Pier Construction – Saltwater-resistant alternative to steel and wood structures.

-

Shipbuilding – Used for non-structural components requiring lightweight and corrosion resistance.

5.3. Infrastructure and Construction

-

Bridges and Walkways – Used in pedestrian bridges and access structures.

-

Railway and Roadside Applications – Non-conductive structures for railway signal supports and power substations.

5.4. Electrical and Telecommunications

-

Power Distribution – Safe for high-voltage environments where metal structures would create electrical hazards.

-

Telecom Towers – Used for antenna structures and communication panel support.

6. Conclusion

FRP EZ Angle provides an excellent alternative to steel, aluminum, and wood, particularly in corrosive, high-voltage, and moisture-exposed environments. It is lightweight, durable, non-conductive, and easy to install, making it a preferred choice for industrial, marine, construction, and electrical applications.

FRP EZ Angle

시리즈 :

주요제품 >애플리케이션

Industrial Applications,Marine & Offshore,Infrastructure & Construction,Electrical & Telecommunication

상표명 :

TF컴포지트

상품명 :

FRP EZ Angle

재료 :

유리 섬유

색상 :

Gray,Other

자주하는 질문

질문 :

How long do FRP Special-Shaped Parts last?

ㅏ :

FRP Special-Shaped Parts have a service life of 25+ years, significantly outlasting many traditional materials such as wood (5-10 years) or steel (10-15 years, depending on conditions).

질문 :

Can FRP Special-Shaped Parts be used outdoors?

ㅏ :

Yes! FRP Special-Shaped Parts are highly UV-resistant and weatherproof, making them ideal for outdoor use in harsh environments like marine applications, chemical plants, and infrastructure.

질문 :

What are the typical dimensions and sizes of FRP Special-Shaped Parts?

ㅏ :

The dimensions of FRP Special-Shaped Parts vary greatly depending on the application and design. However, common sizes include: Length: Can be customized based on the project requirements (commonly 3m to 6m). Thickness: Typically 3mm to 50mm or more depending on strength needs. Width: Can be tailored based on the required shape and function (from small profiles to large sheets). Custom shapes such as curved, angled, and hollow profiles can be created to match exact design specifications.

기타 관련 제품